A kind of production method of smelting furnace body lining material for sodium silicate processing

A production method and smelting furnace technology, applied in silicate, alkali metal silicate and other directions, can solve the problems of low strength, affecting the service life of furnace lining materials, etc., to achieve strong use safety, ensure efficient processing, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

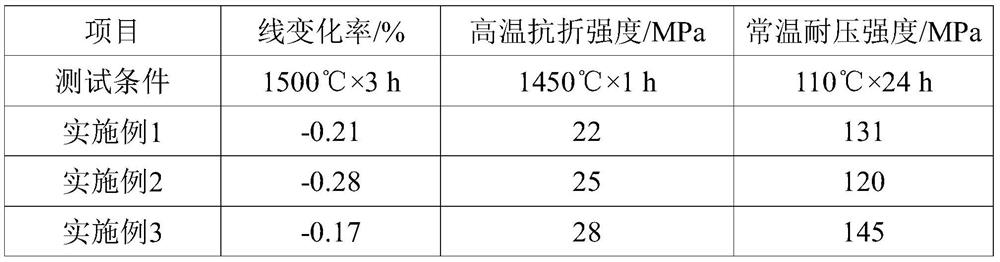

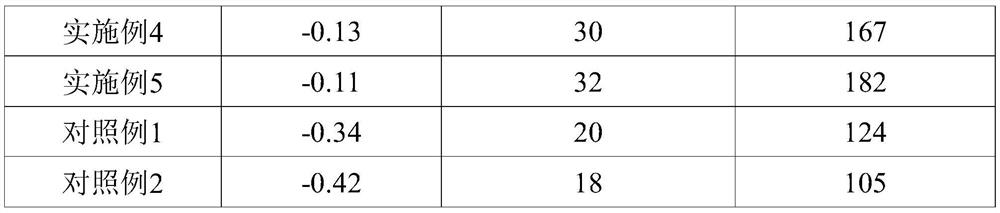

Examples

Embodiment 1

[0035] (1) Formula design: made of 10kg bauxite, 2.5kg wollastonite, 0.8kg asbestos wool, 0.5kg sucrose and 0.05kg lanthanum oxide;

[0036] (2) Mixing: Add the above-mentioned raw materials into a high-speed mixer, and mix for 10 minutes at 800r / min to obtain the mixture;

[0037] (3) Paste preparation: add 10kg of water to the mixture, and make paste through high-speed stirring;

[0038] (4) Heat treatment: heat the prepared paste to 120-125°C at a heating rate of 5°C / min and keep it warm until the water evaporates, and continue to heat at a heating rate of 5°C / min to 175-180°C and keep it for 0.5h , then immediately transferred to 70°C environment for 1 hour, then transferred to 0°C environment for 1 hour, and finally returned to 25°C naturally;

[0039] (5) Flour making: The solid obtained after heat treatment is made into coarse powder through a crusher, and then fine powder is made through a grinding machine to obtain the furnace body lining of the melting furnace.

Embodiment 2

[0041] Taking Example 1 as a comparison, set Example 2 in which phenolic resin 2123 is used as the binding agent instead of sucrose, and the rest of the operation steps are exactly the same as Example 1.

Embodiment 3

[0043] Taking Example 1 as a comparison, set up Example 3 in which the binding agent is sucrose derivatives instead of sucrose, and the rest of the operation steps are exactly the same as Example 1.

[0044] Preparation of sucrose derivatives: Add 70% ethanol dropwise to the mixture of 200g sucrose and 400g myristic acid until it is completely dissolved, then add 5g concentrated sulfuric acid dropwise, heat to reflux state and keep it warm for 4 hours, after the reaction, concentrate and recover under reduced pressure Ethanol, concentrate the residue and dry it in an oven at 75°C to constant weight, and then grind the dried solid into powder to obtain sucrose derivatives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com