Treatment method of low-concentration acetic acid wastewater containing inorganic metal ions and organic impurities

A low-concentration acetic acid and organic impurity technology, used in natural water treatment, chemical instruments and methods, heating water/sewage treatment, etc. The effect of reducing costs, reducing industrial costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

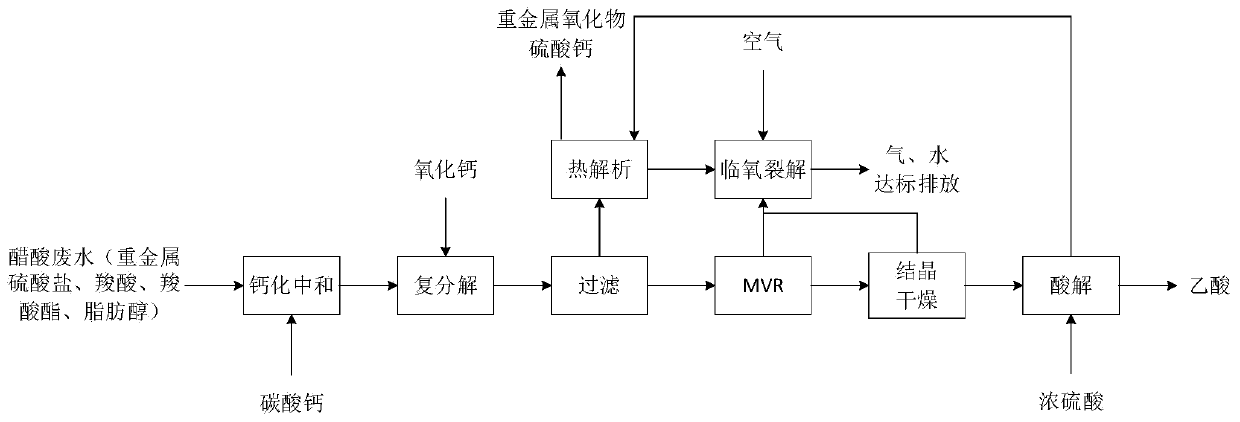

Method used

Image

Examples

Embodiment 1

[0031] The composition of acetic acid wastewater: acetic acid mass fraction 5.5%, iron sulfate mass fraction 3.2%, zinc sulfate mass fraction 0.02%, magnesium sulfate mass fraction 0.02%, manganese sulfate mass fraction 0.04%, methanol mass fraction 0.2%, tert-butanol mass fraction 0.05%, the mass fraction of propanol is 0.05%, the mass fraction of methyl acetate is 0.1%, the mass fraction of propyl acetate is 0.03%, the mass fraction of tert-butyl acetate is 0.02%, the mass fraction of sulfuric acid is 2.7%, and the rest is moisture.

[0032] Add 2000kg of the above-mentioned acetic acid wastewater into the reactor, slowly add 147.9kg of calcium carbonate under stirring, stir at room temperature for 1 hour, the pH value of the wastewater rises to 6.5, then add 48kg of calcium oxide into the reactor, and continue stirring for 1 hour , forming a suspension containing hydroxide, calcium sulfate and calcium acetate.

[0033] Obtain filter cake (wet weight 232.4kg) after above-men...

Embodiment 2

[0036] The composition of acetic acid wastewater: 8.5% mass fraction of acetic acid, 3.9% mass fraction of iron sulfate, 0.02% mass fraction of zinc sulfate, 0.02% mass fraction of magnesium sulfate, 0.04% mass fraction of manganese sulfate, 0.2% mass fraction of methanol, 0.05% mass fraction of ethanol , 0.05% mass fraction of propanol, 0.1% mass fraction of ethyl acetate, 0.03% mass fraction of propyl acetate, 0.02% mass fraction of methyl acetate, 4.5% mass fraction of sulfuric acid, and the rest is moisture.

[0037] Add 10000kg of the above-mentioned acetic acid waste water in the reaction kettle, slowly add 1083.7kg of calcium carbonate under stirring state, stir at room temperature for 2 hours, the pH value of the waste water rises to 6.8, then add 174.9kg of calcium oxide in the reaction kettle, and continue to stir for 1.5 Hours, a suspension containing hydroxide, calcium sulfate and calcium acetate is formed.

[0038] After the above-mentioned suspension is filtered,...

Embodiment 3

[0041] The composition of acetic acid waste water: acetic acid mass fraction 7.5%, iron sulfate mass fraction 3.9%, zinc sulfate mass fraction 0.02%, magnesium sulfate mass fraction 0.02%, copper sulfate mass fraction 0.02%, manganese sulfate mass fraction 0.04%, methanol mass fraction 0.2 %, mass fraction of tert-butyl alcohol is 0.05%, mass fraction of propanol is 0.05%, mass fraction of methyl acetate is 0.1%, mass fraction of propyl acetate is 0.03%, mass fraction of tert-butyl acetate is 0.02%, mass fraction of sulfuric acid is 3.6%, and the rest for moisture.

[0042] Add 8000kg of the above-mentioned acetic acid wastewater in the reactor, slowly add 784.8kg of calcium carbonate under stirring, stir at room temperature for 1.5 hours, the pH value of the wastewater rises to 6.4, then add 103.9kg of calcium oxide in the reactor, and continue to stir for 1 Hours, a suspension containing hydroxide, calcium sulfate and calcium acetate is formed.

[0043] After filtering the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com