Preparation method of low-surface-residual-alkali nickel cobalt manganese ternary positive electrode material

A nickel-cobalt-manganese ternary and positive electrode material technology, which is applied in chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of active lithium loss, material specific capacity reduction, and difficulty in industrialization, etc., to reduce residual alkali , reduce pH value, improve the effect of consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

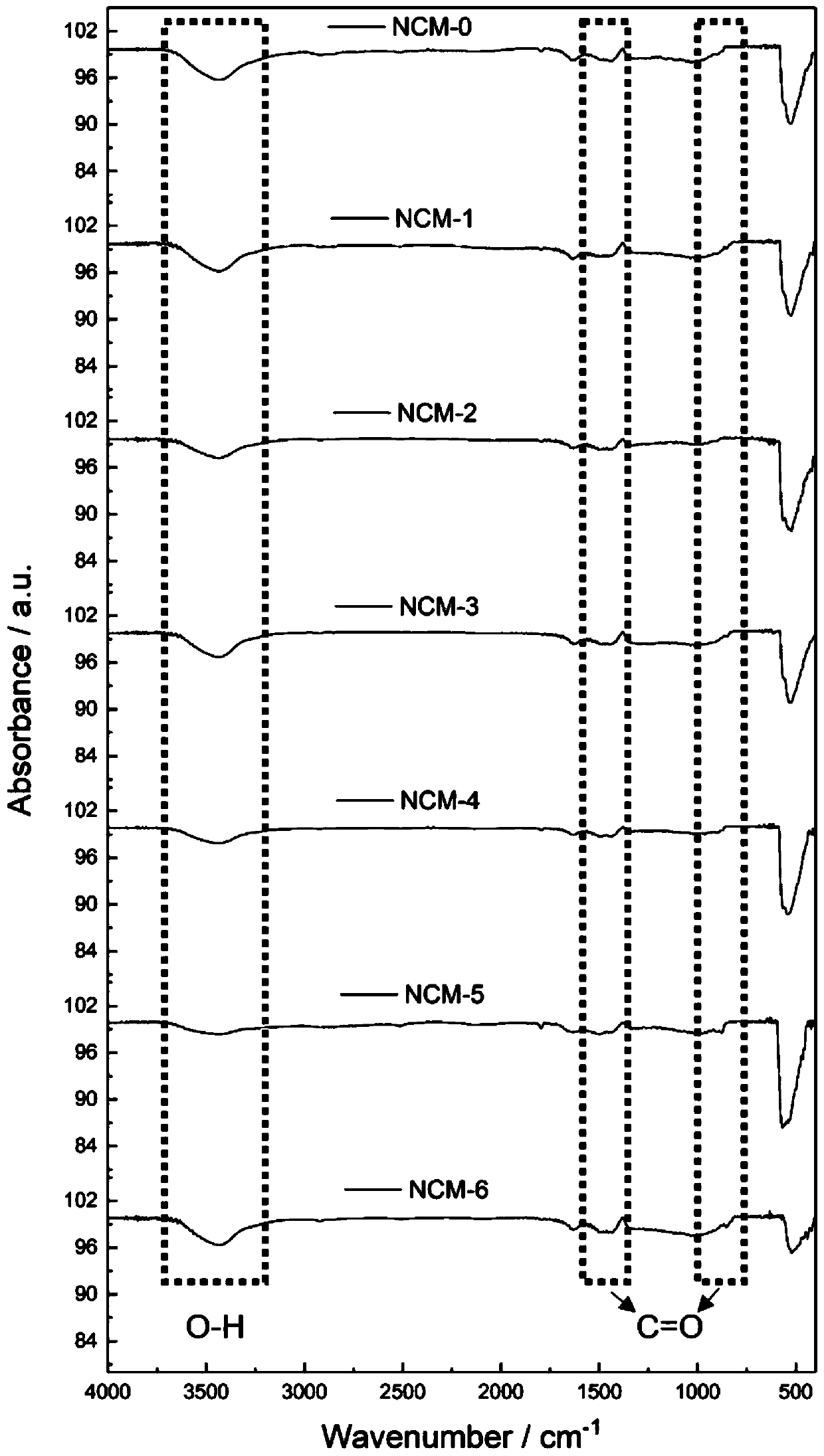

Embodiment 1

[0062] Step (1): take boric acid (H 3 BO 3 ) solid powder 0.006g, it was added to 100mL ethanol and stirred until dissolved to obtain a boric acid concentration of 0.001mol / L ethanol solution containing boric acid, measure 1mL for subsequent use.

[0063] Step (2): Weigh 1g of nickel-cobalt-manganese ternary cathode material LiNi 0.90 co 0.06 mn 0.04 o 2 , the material was added to 1 mL of ethanol solution containing boric acid, stirred for 1 min, filtered, and the obtained precipitate was repeatedly washed with absolute ethanol three times, and then dried in a vacuum oven at 80° C. for 2 h.

[0064] Step (3): put the dried nickel-cobalt-manganese ternary positive electrode material into a tube furnace, and calcine it in an oxygen atmosphere, calcine it at 400°C for 240 minutes, and cool it down to room temperature naturally to obtain a nickel with low residual alkali on the surface. Cobalt-manganese ternary cathode material, the obtained material is marked as NCM-1.

[...

Embodiment 2

[0073] Step (1): take boric acid (H 3 BO 3 ) solid powder 0.0025g, it was added to 5mL ethanol and stirred until dissolving to obtain a boric acid concentration of 0.008mol / L containing boric acid ethanol solution.

[0074] Step (2): Weigh 1g of nickel-cobalt-manganese ternary cathode material LiNi 0.90 co 0.06 mn 0.04 o 2 , put the material into 5 mL ethanol solution containing boric acid, stir for 5 min, filter, and rinse the obtained precipitate with absolute ethanol three times, and then dry it in a vacuum oven at 80° C. for 2 h.

[0075] Step (3): Put the dried nickel-cobalt-manganese ternary positive electrode material into a tube furnace, calcinate in an oxygen atmosphere, calcinate at 400°C for 260min, and cool naturally to room temperature to obtain a nickel with low surface residual alkali Cobalt-manganese ternary cathode material, the obtained material is marked as NCM-2.

[0076] ICP-AES test results show that the elemental composition is LiNi 0.901 co 0.05...

Embodiment 3

[0084] Step (1): take boric acid (H 3 BO 3 ) solid powder 0.0099g, it was added to 10mL ethanol and stirred until dissolving to obtain a boric acid concentration of 0.016mol / L containing boric acid ethanol solution.

[0085] Step (2): Weigh 1g of nickel-cobalt-manganese ternary cathode material LiNi 0.90 co 0.06 mn 0.04 o 2 , the material was put into 10 mL of ethanol solution containing boric acid and stirred for 5 min, filtered, and the obtained precipitate was repeatedly washed with absolute ethanol three times, and then dried in a vacuum oven at 80° C. for 2 h.

[0086] Step (3): Put the dried nickel-cobalt-manganese ternary positive electrode material into a tube furnace, calcinate it in an oxygen atmosphere, and calcinate it at 420°C for 240 minutes, then cool it naturally to room temperature to obtain a nickel with low surface residual alkali Cobalt-manganese ternary cathode material, the obtained material is marked as NCM-3.

[0087] ICP-AES test results show that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com