Garbage and sludge high pressure themolysis processing method, system and application thereof

A treatment method and pyrolysis reactor technology, applied in the field of solid waste treatment technology, can solve problems such as waste of resources and energy, deterioration of natural properties and stability of landfill land, secondary pollution of leachate, etc., and achieve improvement Treatment efficiency, reducing the probability of dioxin generation, and the effect of solving air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

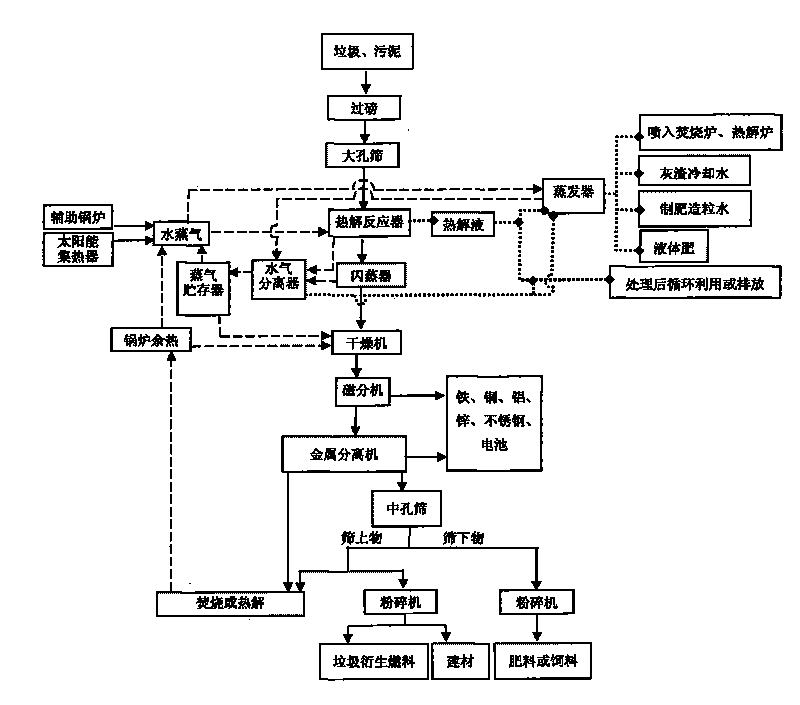

[0062] See the basic process flow figure 1 . A brief description is as follows:

[0063] The dewatered sludge composition of a sewage treatment plant in a city in Guangdong Province is as follows, organic matter (C) 29.5% (by dry weight), N 2.1% (by dry weight), P 2 o 5 1.9% (by dry weight), K 2 O 0.7% (by dry weight), calorific value is 2800Kcal / Kg, and moisture content is 80%.

[0064] The composition of domestic waste in this city is as follows (calculated by wet weight): 0.79% metal, 3.06% plastic, 69.78% kitchen waste, 18.39% paper, 3.32% textile, 4.66% inert substance, and 42% water content.

[0065]The above domestic garbage and sludge are weighed, and the garbage is sent to a large-hole sieve. After the garbage with a size larger than 400mm is screened out, it is mixed with the sludge at a volume ratio of 7:3, and the material is sent to the pyrolysis reactor by the conveyor belt. Saturated water vapor is provided by the solar heat collector, and when the amount ...

Embodiment 2

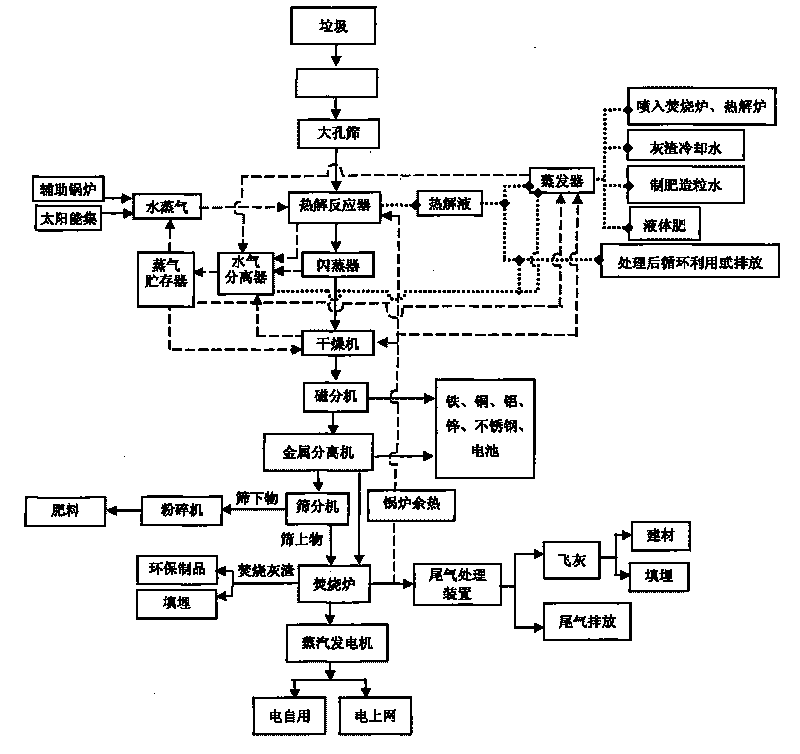

[0067] Waste-to-energy pretreatment process see figure 2 . A brief description is as follows:

[0068] The composition of a municipal solid waste is as follows (by wet weight): metal 1.88%, plastic 14.60%, kitchen waste 39.18%, paper 15.9%, dust 23.32%, other 5.12%, moisture content 54%.

[0069] The above-mentioned domestic garbage is weighed and sent to a large-hole sieve, and after the garbage with a size larger than 500mm is screened out, the material is sent to the pyrolysis reactor through a conveyor belt. Saturated water vapor is provided by the solar heat collector, and when the amount of steam is insufficient, add the steam generated by the auxiliary boiler to make the internal pressure of the pyrolysis reactor reach 14atm, and the temperature is 180-190°C, keep it for 1 hour and then discharge the steam, when the pressure drops to 6atm , open the drain valve to discharge the pyrolysis solution. Continue to reduce the pressure of the pyrolysis reactor, and when th...

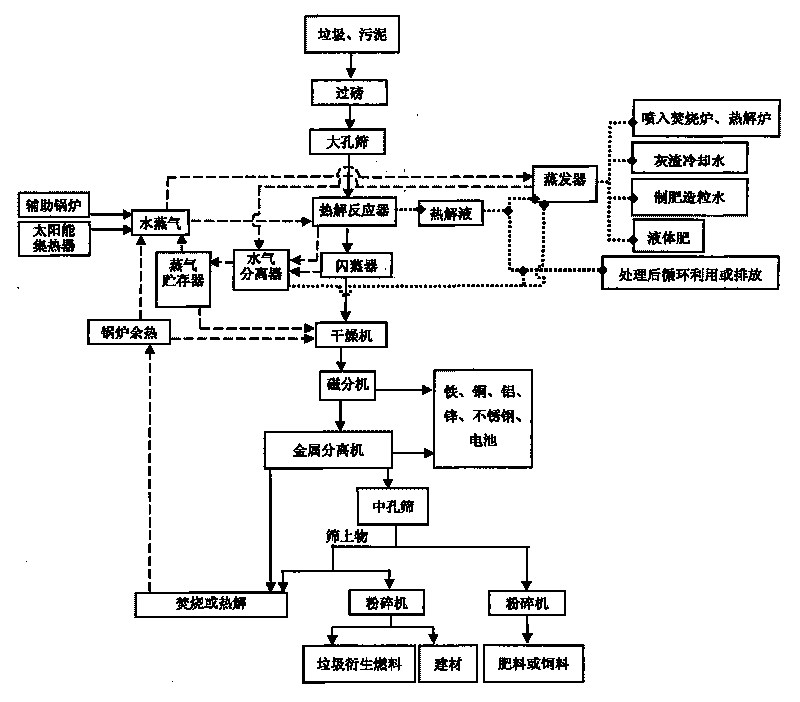

Embodiment 3

[0071] The composition of domestic waste in a large community is (by wet weight): 0.79% metal, 18.06% plastic, 39.78% kitchen and yard waste, 13.39% paper, 4.32% textile, 23.66% inert material, and 36% moisture content. The domestic garbage is sent into the pyrolysis reactor through the conveyor belt, and steam is introduced to make the temperature of the reactor reach 190° C., and the pressure is controlled at 15 atm for 0.5 hours. Reduce the pressure, open the drain valve, and discharge the pyrolysis solution. Close the drain valve, continue to reduce the pressure, and then discharge the material into the flash evaporator. After the flash evaporation is completed, the material is transported from the flash evaporator to the dryer with a screw conveyor. The steam generated by decompression, the secondary steam generated by the evaporator and the steam generated by flash evaporation are led to the water-gas separator through the pipeline, and the steam part is led to the stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com