Discharge plasma diffusion bonding method for silicon carbide ceramic

A technology of discharge plasma and silicon carbide ceramics is applied in the field of connection of ceramic materials, which can solve the problems of stress concentration at the connection, poor air tightness of the joint, and poor heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

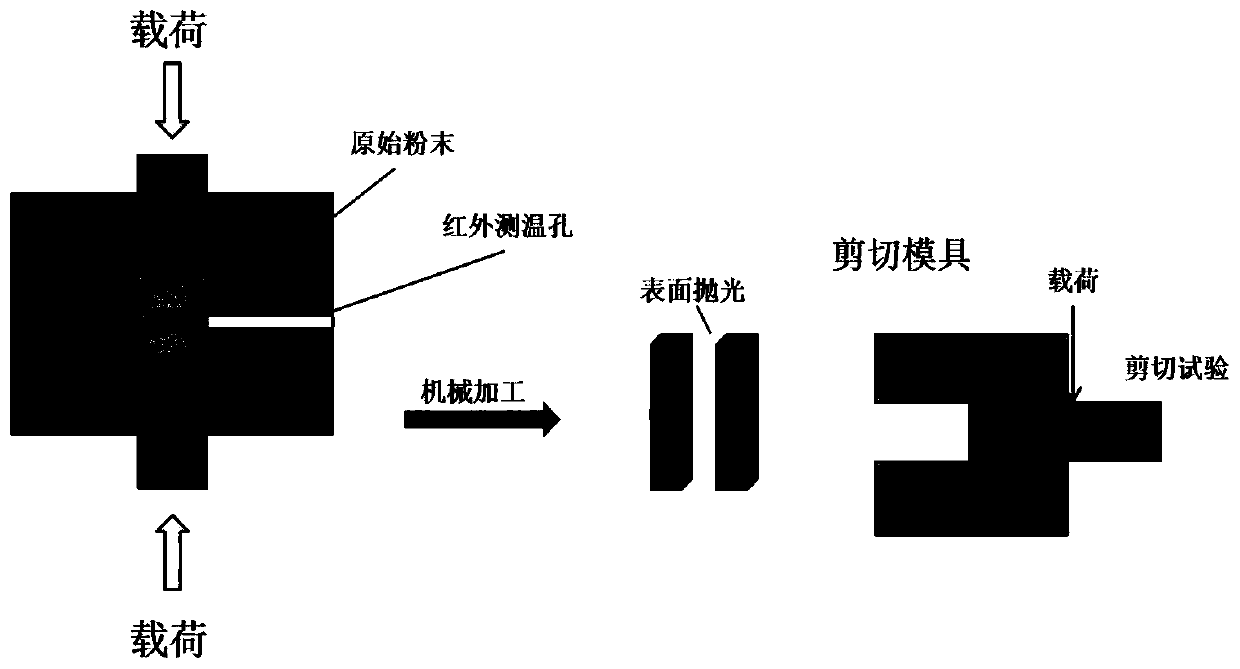

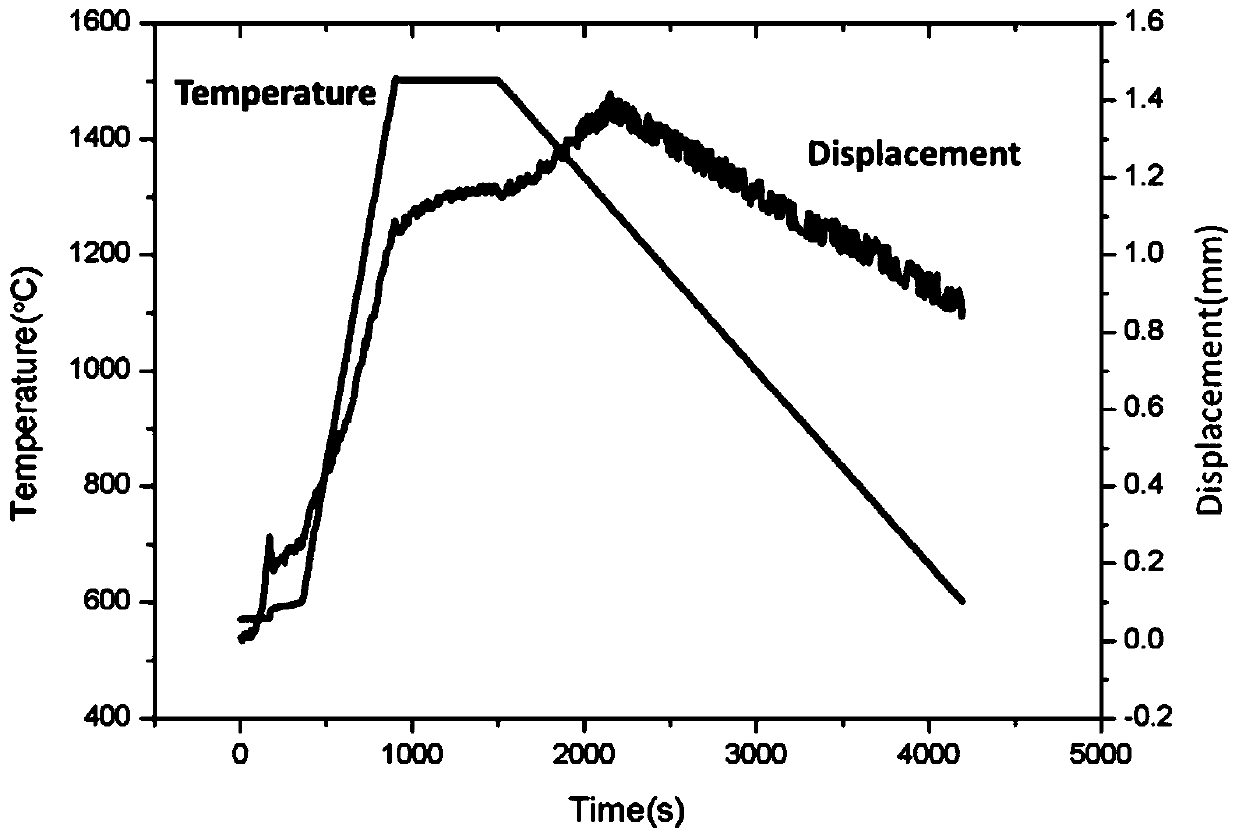

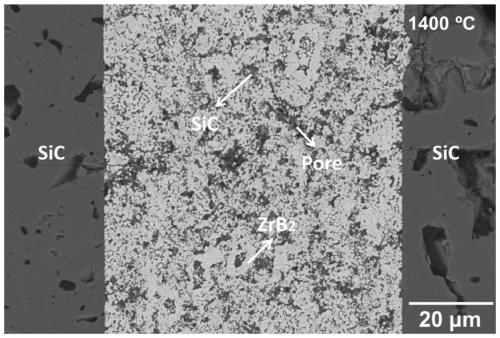

[0033] In this embodiment, the connection method of the SiC ceramic connected by the discharge plasma diffusion connection of the multiphase ceramic connection layer is as follows:

[0034] 1. Preparation of connecting layer powder

[0035] With 69.1% ZrH 2 powder, 10.5% Si powder and 20.4% B 4 C powder is mixed as the raw material and poured into the agate grinding bowl, using absolute alcohol as the grinding medium, grinding for 3 hours until completely mixed, and then placed in a vacuum drying oven at 60°C for 6 hours to obtain the connecting layer powder;

[0036] 2. Preparation before diffusion connection

[0037] Cylindrical SiC ceramics were sliced with an internal circle slicer Cut into SiC ceramic sheets with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing fluids to polish the connecting surface of the SiC ceramic sheets in turn, put the polished SiC ceramic sheets into an alcohol solution for ultrasonic cleaning, and air-dry at room te...

Embodiment 2

[0043] In this embodiment, the connection method of the SiC ceramic connected by the discharge plasma diffusion connection of the multiphase ceramic connection layer is as follows:

[0044] 1. Preparation of connecting layer powder

[0045] With 69.1% ZrH 2 powder, 10.5% Si powder and 20.4% B 4 C powder is mixed as the raw material and poured into the agate grinding bowl, using absolute alcohol as the grinding medium, grinding for 3 hours until completely mixed, and then placed in a vacuum drying oven at 60°C for 6 hours to obtain the connecting layer powder;

[0046] 2. Preparation before diffusion connection

[0047] Cylindrical SiC ceramics were sliced with an internal circle slicer Cut into SiC ceramic sheets with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing fluids to polish the connecting surface of the SiC ceramic sheets in turn, put the polished SiC ceramic sheets into an alcohol solution for ultrasonic cleaning, and air-dry at room te...

Embodiment 3

[0053] In this embodiment, the connection method of the SiC ceramic connected by the discharge plasma diffusion connection of the multiphase ceramic connection layer is as follows:

[0054] 1. Preparation of connecting layer powder

[0055] With 69.1% ZrH 2 powder, 10.5% Si powder and 20.4% B 4 C powder is mixed as the raw material and poured into the agate grinding bowl, using absolute alcohol as the grinding medium, grinding for 3 hours until completely mixed, and then placed in a vacuum drying oven at 60°C for 6 hours to obtain the connecting layer powder;

[0056] 2. Preparation before diffusion connection

[0057] Cylindrical SiC ceramics were sliced with an internal circle slicer Cut into SiC ceramic sheets with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing fluids to polish the connecting surface of the SiC ceramic sheets in turn, put the polished SiC ceramic sheets into an alcohol solution for ultrasonic cleaning, and air-dry at room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com