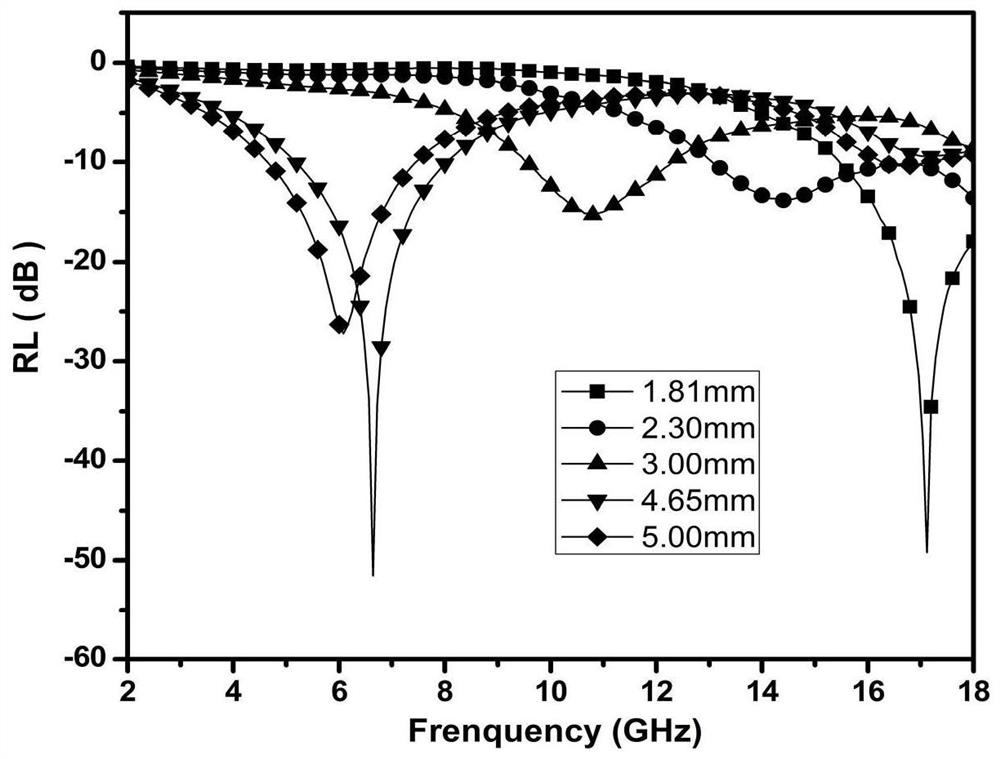

a kind of hals-fe 3 o 4 @cComposite materials and their preparation methods and applications

A composite material and core material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor electromagnetic matching, low applicable frequency band, high density, etc., and achieve the elimination of retroreflection, increase the probability of weakening, and high performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

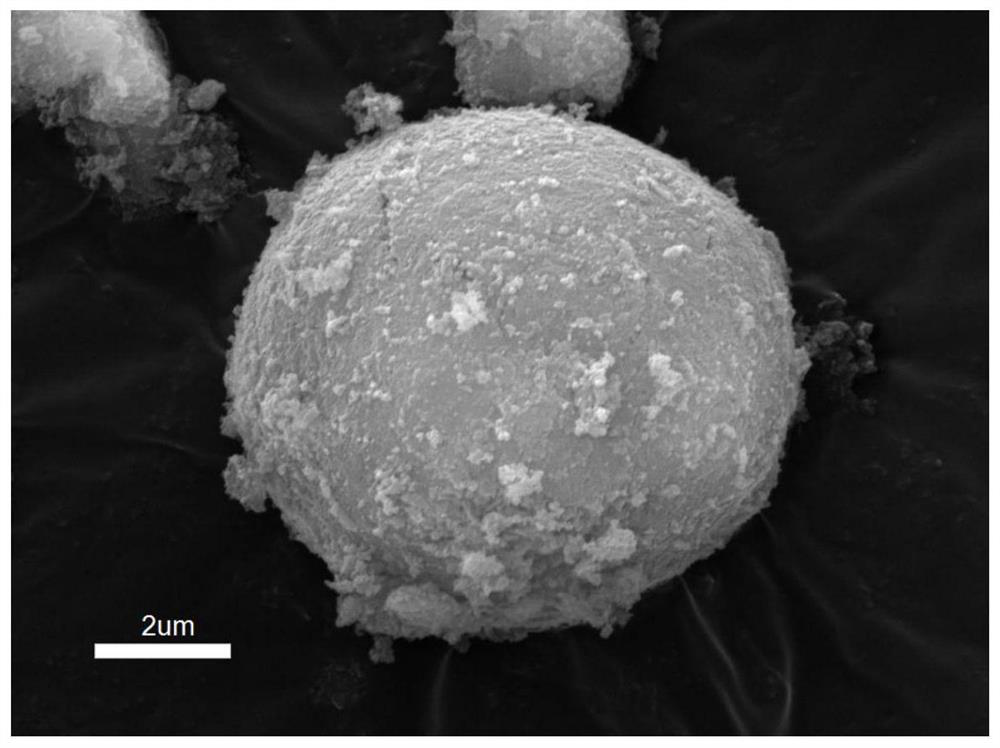

[0056] Take 50g of halloysite through a 200-mesh standard sieve and disperse it in 50mL of deionized water, prepare the halloysite powder into a suspension with a solid content of 30%, then add 1.5g of polyethylene glycol, ultrasonic for 30min, and magnetically After stirring for 2 hours, a cloudy solution was obtained. After stirring for 2 hours, the cloudy solution was spray-granulated in a drying tower at 200°C to obtain microspheres with an average particle size of 5 μm, which were calcined at 500°C for 2 hours.

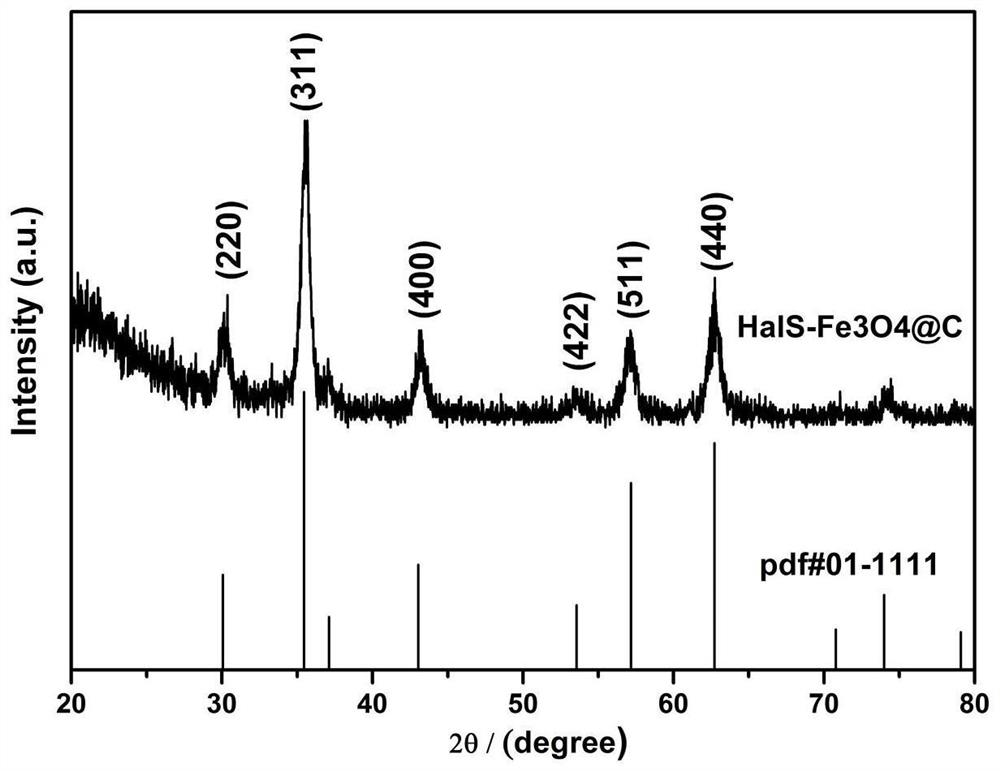

[0057] Get calcined halloysite microspheres 0.05g, (NH 4 ) 2 FeSO 4 ·6H 2 O 0.322g, (NH 4 Fe(SO 4 ) 2 12H 2 (O) 0.793g into a three-necked flask, add 150ml of deionized water, stir and heat at a constant speed to 50°C, add 5ml of ammonia water drop by drop, react for 30min and then magnetically separate, wash 3 times with water, wash 3 times with ethanol, and return to 60°C Dry in a vacuum oven for 12h to obtain halloysite balls / Fe 3 o 4 . Take 0.1g of ...

Embodiment 2

[0059] Take 40g of halloysite through a 200-mesh standard sieve and disperse it in 60mL of deionized water, prepare the halloysite powder into a suspension with a solid content of 40%, then add 2g of sodium hexametaphosphate, sonicate for 30min, and stir magnetically at room temperature After 2 hours, a cloudy solution was obtained. After stirring for 2 hours, the cloudy solution was spray-granulated in a drying tower at 190°C to obtain microspheres with an average particle size of 5 μm, which were calcined at 600°C for 2 hours.

[0060] Get calcined halloysite microspheres 0.1g, (NH 4 ) 2 FeSO 4 ·6H 2 O 0.322g, (NH 4 Fe(SO 4 ) 2 12H 2 O) 0.793g into a three-necked flask, add 150ml of deionized water, stir and heat at a constant speed to 50°C, add 5ml of ammonia water drop by drop, react for 30min, then magnetically separate, wash 3 times with water, wash 3 times with ethanol, and return to 60°C Dry in a vacuum oven for 12h to obtain halloysite balls / Fe 3 o 4 . Take ...

Embodiment 3

[0064] According to the method of Example 1, the halloysite powder is prepared into a suspension and a turbid liquid with a solid content of 30%. After stirring for 2 hours, the liquid is sprayed and granulated in a drying tower at 180°C to obtain a powder with an average particle size of 5 μm. The microspheres were calcined at 700°C for 2h. Get calcined halloysite microspheres 0.2g, (NH 4 ) 2 FeSO 4 ·6H 2 O 0.322g, (NH 4 Fe(SO 4 ) 2 12H 2 O) 0.793g was put into a three-necked flask, stirred at a constant speed and heated to 50°C, and 5ml of ammonia water was added dropwise, reacted for 30 minutes, separated by magnetic force, washed 3 times with water and 3 times with ethanol, then dried in a vacuum oven at 60°C for 12 hours to obtain Halloy Ball / Fe 3 o 4 . Take 0.1g of the dried product and disperse it in a mixture containing 8ml of water, 3.2ml of ethanol and 0.04ml of ammonia water. After ultrasonic dispersion for 30min, add 0.06g of resorcinol and continue stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com