Steam burning supporting type torch burner

A torch combustion and burner technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of not obvious smoke suppression effect, black smoke from the torch, and large steam volume, etc., and achieve the improvement of steam carrying air The effect of high capacity, smokeless combustion capacity and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

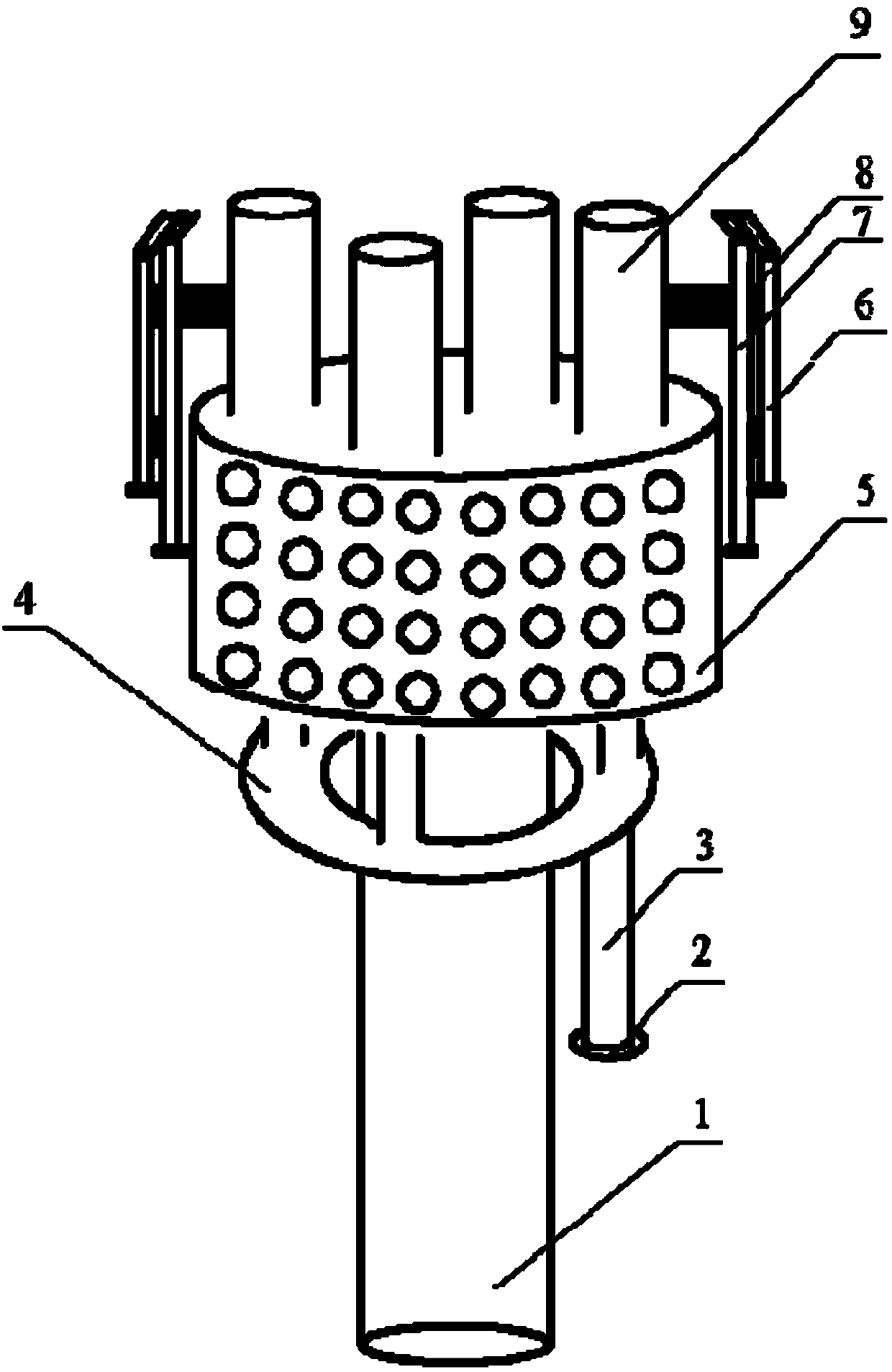

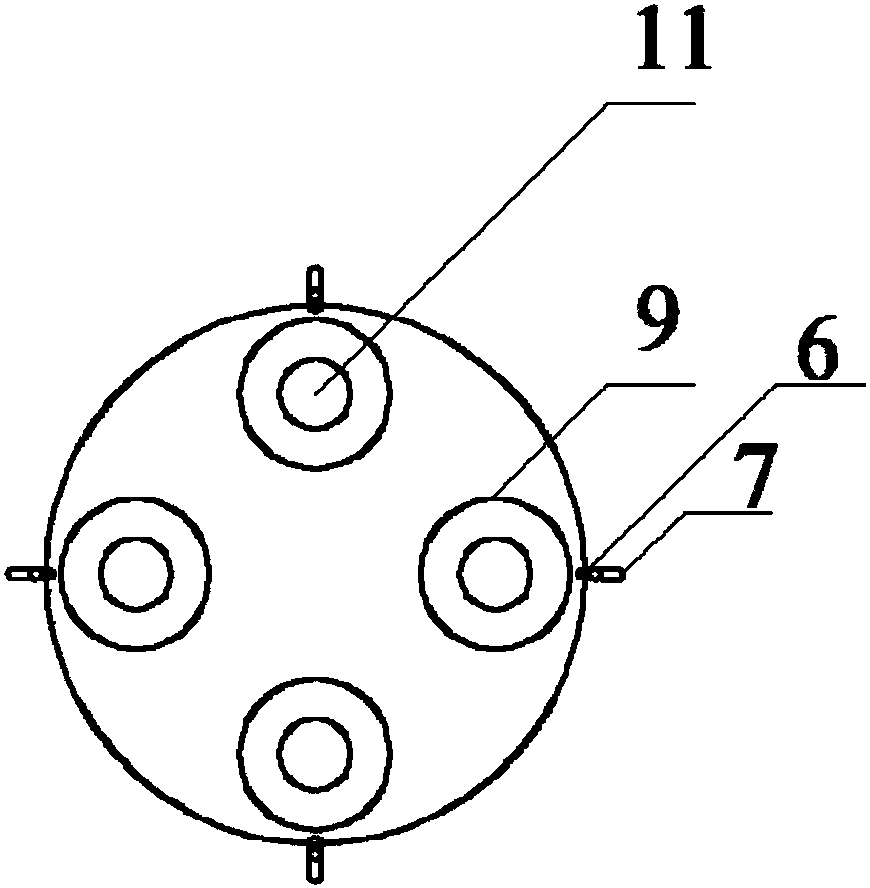

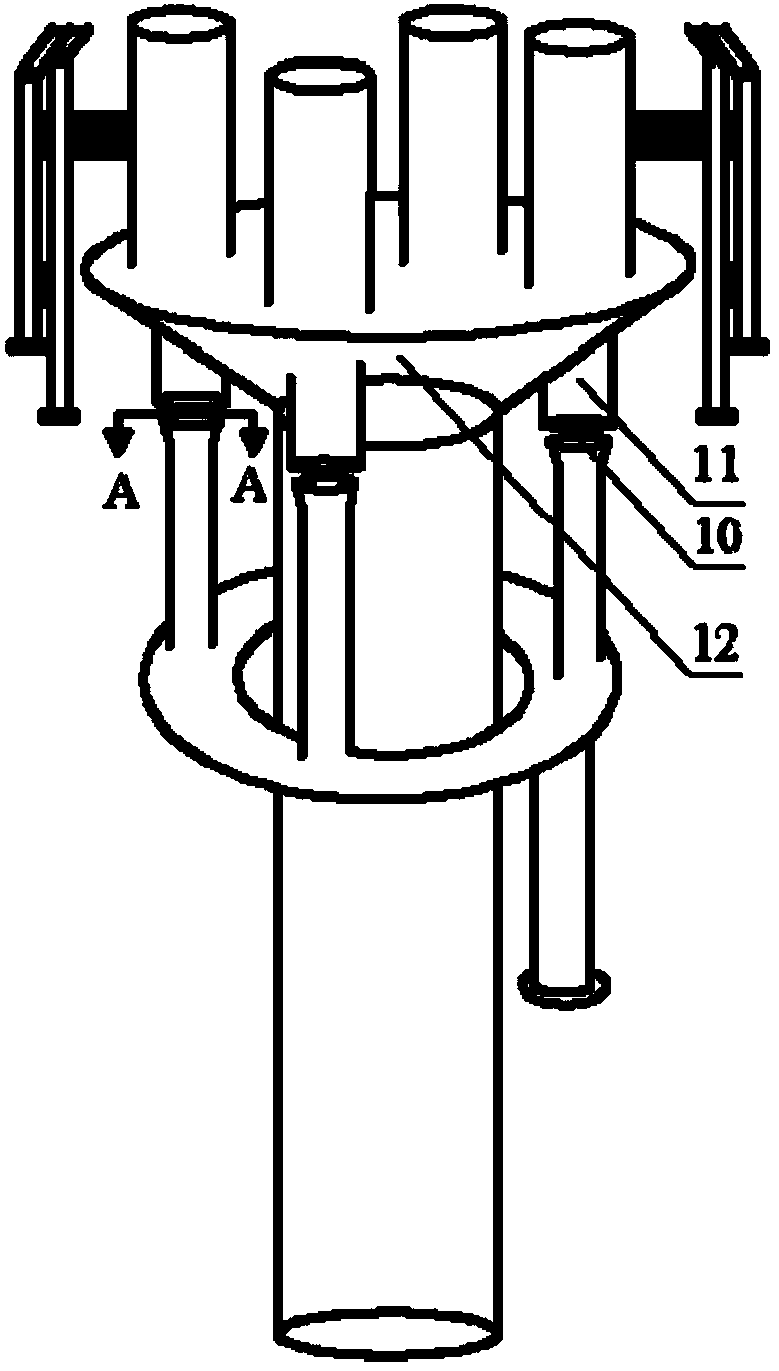

[0026] A steam-assisted combustion type flare burner, such as Figure 1-4 as shown,

[0027] 1 Flare gas main pipe, the main pipe and the flare pipe network are connected by flange;

[0028] 2 The smoke elimination steam inlet, the smoke elimination steam inlet and the steam pipeline are connected by flanges;

[0029] 3 steam main pipe;

[0030] 4 Steam coil, the diameter of the coil should be slightly larger than the diameter of the flare gas main pipe, and the coil is equipped with steam branch pipes with the same number as the number of burners;

[0031] 5 Noise-absorbing cover, the porosity is 1%-, the material is stainless steel, the thickness is 5mm, and 50mm sound-absorbing cotton is installed inside;

[0032] 6 igniter, the height of the top of the igniter is the same as that of the long light;

[0033] 7 permanent lights, the top of the permanent lamp should be slightly higher than the top of the burner;

[0034] 8 The fixed wing plate, the igniter and the long l...

Embodiment 2

[0043] A steam-assisted combustion type flare burner, such as Figure 1-4 as shown,

[0044] 1 Flare gas main pipe, the main pipe and the flare pipe network are connected by flange;

[0045] 2 The smoke elimination steam inlet, the smoke elimination steam inlet and the steam pipeline are connected by flanges;

[0046] 3 steam main pipe;

[0047] 4 Steam coil, the diameter of the coil should be slightly larger than the diameter of the flare gas main pipe, and the coil is equipped with steam branch pipes with the same number as the number of burners;

[0048]5 Noise-absorbing cover, the porosity is 3%, the material is stainless steel, the thickness is 10mm, and 100mm sound-absorbing cotton is installed inside;

[0049] 6 igniter, the height of the top of the igniter is the same as that of the long light;

[0050] 7 permanent lights, the top of the permanent lamp should be slightly higher than the top of the burner;

[0051] 8 The fixed wing plate, the igniter and the long l...

Embodiment 3

[0060] A steam-assisted combustion type flare burner, such as Figure 1-4 as shown,

[0061] 1 Flare gas main pipe, the main pipe and the flare pipe network are connected by flange;

[0062] 2 The smoke elimination steam inlet, the smoke elimination steam inlet and the steam pipeline are connected by flanges;

[0063] 3 steam main pipe;

[0064] 4 Steam coil, the diameter of the coil should be slightly larger than the diameter of the flare gas main pipe, and the coil is equipped with steam branch pipes with the same number as the number of burners;

[0065] 5 Noise-absorbing cover, the porosity is 2%, the material is stainless steel, the thickness is 7mm, and 70mm sound-absorbing cotton is installed inside;

[0066] 6 igniter, the height of the top of the igniter is the same as that of the long light;

[0067] 7 permanent lights, the top of the permanent lamp should be slightly higher than the top of the burner;

[0068] 8 The fixed wing plate, the igniter and the long li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com