Degradable plastic bag and production method thereof

A technology for plastic bags and materials, applied in the field of degradable plastic bags and their preparation, can solve problems such as unsatisfactory antibacterial properties, and achieve the effects of reducing white pollution, improving wettability, and increasing mesh density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

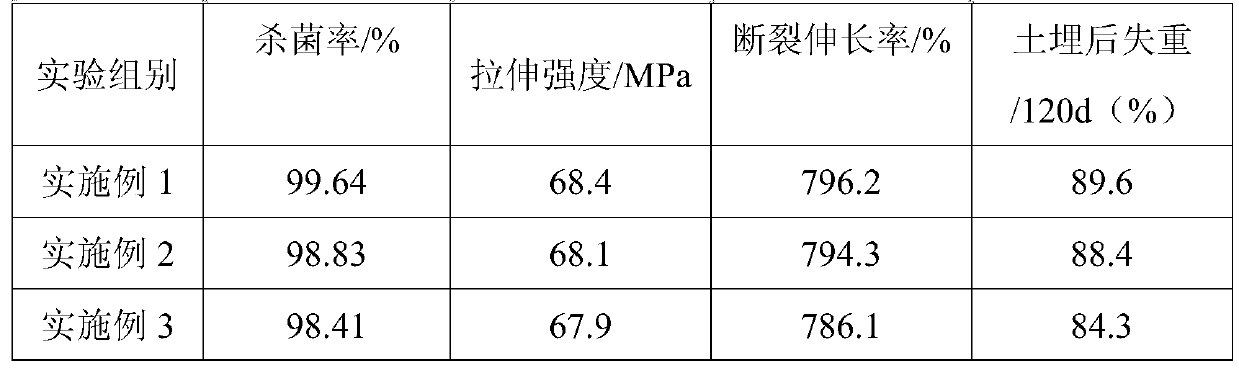

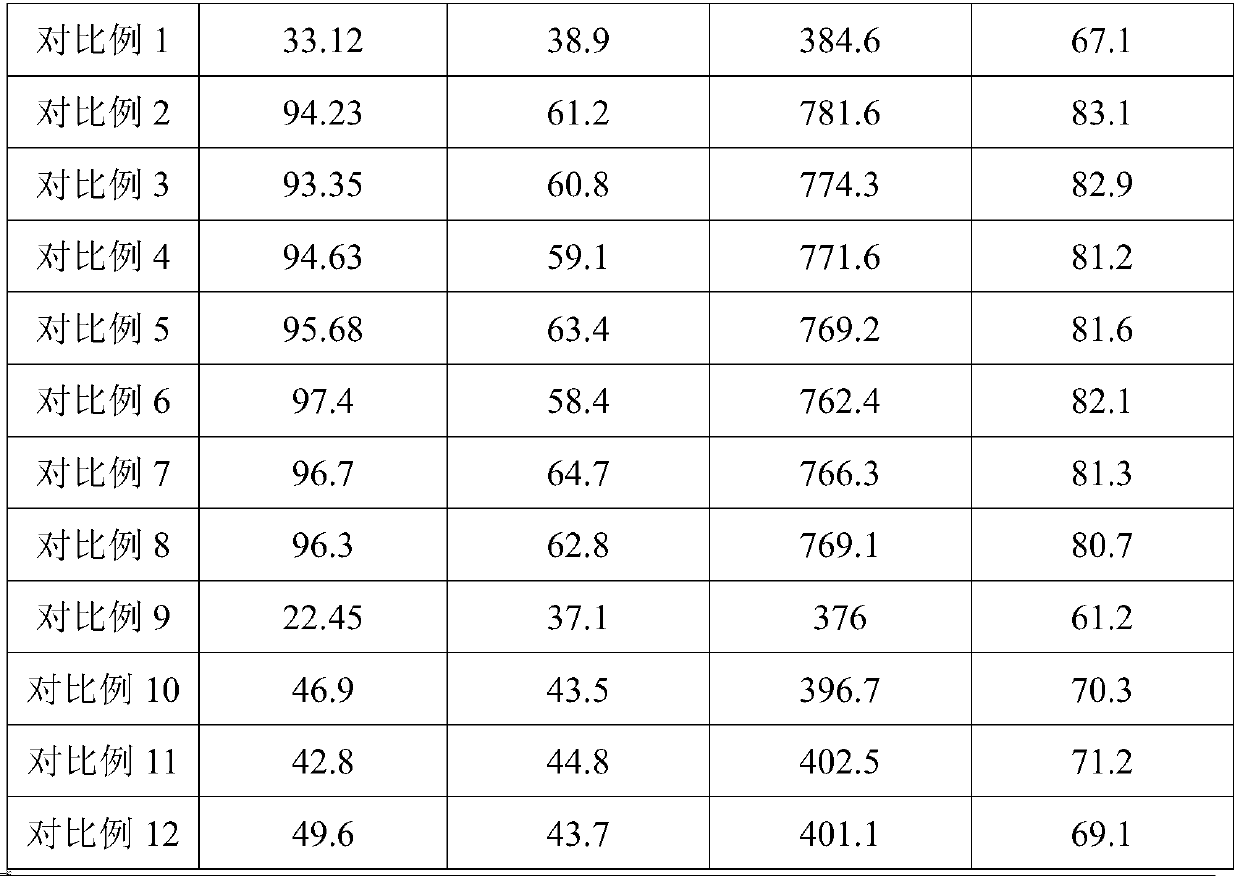

Examples

preparation example Construction

[0026] A kind of preparation method of degradable plastic bag that the present invention proposes, comprises the following steps:

[0027] S1: After drying the lignosulfonate, dissolve it in NaOH solution with a substance concentration of 10mol / L, heat and stir in a water bath, and raise the temperature to 70-80°C, then add epichlorohydrin and mix evenly, at 70-75°C After stirring under constant temperature reflux for 4-6 hours, washing until the pH value is 7, and vacuum drying at 100-110°C, the material I is obtained;

[0028] S2: Mix pentaerythritol, suberic acid and polylactic acid evenly, and carry out polycondensation reaction at 150-180° C. for 2-4 hours under nitrogen atmosphere to obtain material II;

[0029] S3. Add ethylene-acrylic acid copolymer, linear low-density polyethylene and polyvinyl alcohol to the material II, mix evenly, let cool, wash until neutral, and finally perform solid-liquid separation to obtain material III;

[0030] S4, mix material III with di...

Embodiment 1

[0033] A kind of degradable plastic bag, in weight part, comprises following raw material: ethylene-acrylic acid copolymer 100 parts, lignin sulfonate 18 parts, epichlorohydrin 6.5 parts, modified antibacterial agent 7.5 parts, linear low Density polyethylene 11 parts, polyvinyl alcohol 20 parts, polylactic acid 6 parts, pentaerythritol 6 parts, suberic acid 4.5 parts, diphenylmethane diisocyanate 3.5 parts, dioctyl phthalate 6.4 parts, silane coupling agent KH -5702.3 parts, 13 parts of bamboo fiber, 5.8 parts of potato starch, 4.9 parts of montmorillonite, 2.8 parts of konjac glucomannan, 5.2 parts of calcium carbonate, 3.3 parts of liquid paraffin, 5.8 parts of ethylene ethyl acrylate, 6.3 parts of glycerin, fat Acyl diethanolamine 5.8 parts.

[0034] The modified antibacterial agent is prepared according to the following process: 5.8 parts by weight of 3,4-dihydroxybenzaldehyde, 6.5 parts of sodium hexametaphosphate, 4.7 parts of diphenylmethane diisocyanate, 2.9 parts of ...

Embodiment 2

[0042] A degradable plastic bag, in parts by weight, comprising the following raw materials: 80 parts of ethylene-acrylic acid copolymer, 24 parts of lignosulfonate, 4 parts of epichlorohydrin, 10 parts of modified antibacterial agent, linear low Density polyethylene 8 parts, polyvinyl alcohol 25 parts, polylactic acid 4 parts, pentaerythritol 8 parts, suberic acid 3 parts, diphenylmethane diisocyanate 5 parts, dioctyl phthalate 4 parts, silane coupling agent KH -5703 parts, 9 parts of bamboo fiber, 8 parts of potato starch, 2 parts of montmorillonite, 5 parts of konjac glucomannan, 4 parts of calcium carbonate, 5 parts of liquid paraffin, 4 parts of ethylene ethyl acrylate, 9 parts of glycerin, fat Acyl diethanolamine 3 parts.

[0043]The modified antibacterial agent is prepared according to the following process: 4 parts by weight of 3,4-dihydroxybenzaldehyde, 9 parts of sodium hexametaphosphate, 2 parts of diphenylmethane diisocyanate, 5 parts of nitric acid with a mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com