A kind of anti-scouring hydraulic surface protection block and its preparation method

A face protection block and anti-scouring technology, which is applied in chemical instruments and methods, cement production, coastline protection, etc., can solve the problem of low benefit of anti-scouring and wear protection, failure to improve crack resistance, and insufficient bonding strength of concrete substrates Ideal and other problems, to achieve the effect of good adhesion performance, extended service life and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

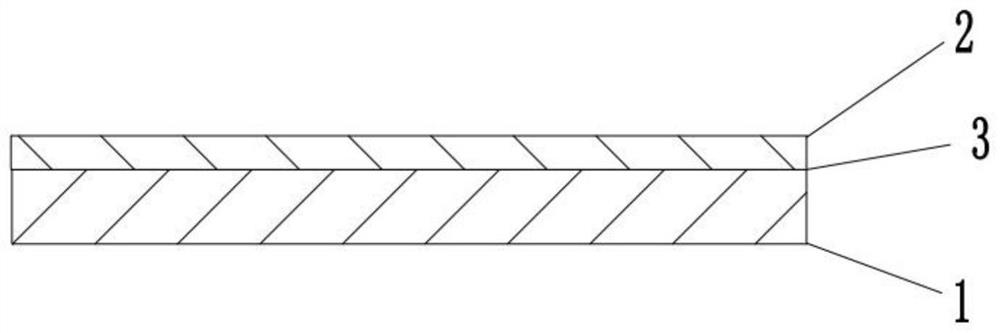

[0037] This embodiment provides an anti-scouring hydraulic face protection block, which includes a concrete block 1 and a geopolymer layer 2 covered on its surface, the geopolymer layer 2 and the concrete block 1 An adhesive is provided between them; the geopolymer layer 2 is the geopolymer in the form of a coating, which is bonded to the surface of the concrete block 1 through an adhesive. like figure 1 As shown, there is an adhesive interface 3 between the concrete block 2 and the geopolymer layer 1 .

[0038] The construction steps are:

[0039] In step a, the raw materials are mixed, and water is added to form a gelled material;

[0040] Step b, the configuration of the alkali excitation solution;

[0041] Step c, uniformly mixing the gelling material in step a and the alkali excitation solution in step b;

[0042] Step d, coating the adhesive on the surface of the concrete block;

[0043] Step e, coating the mixture obtained in step c on the surface of the concrete b...

Embodiment 2

[0053] The geopolymer selected in this embodiment comprises the following components by weight: 22 parts of slag powder, 35 parts of fly ash, 22 parts of desulfurized gypsum, 7 parts of liquid water glass, 8 parts of sodium hydroxide, 35 parts of fine sand, 25 parts of water. The selected adhesive is carbene interface agent.

[0054] The specific steps of preparing the abrasion-resistant hydraulic face armor block in this embodiment are the same as those in Embodiment 1. The hydraulic face protection block comprises a concrete block 1 and a geopolymer layer 2 covered on its surface, and an adhesive is provided between the geopolymer layer 2 and the concrete block 1 . Compared with the traditional concrete block for hydraulic face protection, the hydraulic face protection block prepared in this embodiment has better anti-abrasion performance.

Embodiment 3

[0056] The geopolymer selected in this embodiment comprises the following components by weight: 20 parts of slag powder, 32 parts of fly ash, 25 parts of desulfurized gypsum, 8 parts of liquid water glass, 9 parts of sodium hydroxide, 38 parts of fine sand, 28 parts of water. The adhesive of choice is an acrylic adhesive.

[0057]The specific steps of preparing the abrasion-resistant hydraulic face armor block in this embodiment are the same as those in Embodiment 1. The hydraulic face protection block comprises a concrete block 1 and a geopolymer layer 2 covered on its surface, and an adhesive is provided between the geopolymer layer 2 and the concrete block 1 . Compared with the traditional concrete block for hydraulic face protection, the hydraulic face protection block prepared in this embodiment has better anti-abrasion performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com