Preparation method of nickle-based high temperature and corrosion resistant welding wire

A technology of high temperature resistance and corrosion resistance, which is applied in the field of preparation of nickel-based high temperature resistance and corrosion resistance welding wire, can solve the problems of high corrosion rate and low corrosion rate, achieve good high temperature resistance and corrosion resistance, reduce intergranular corrosion, and improve resistance to corrosion. The effect of corrosion resistance and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

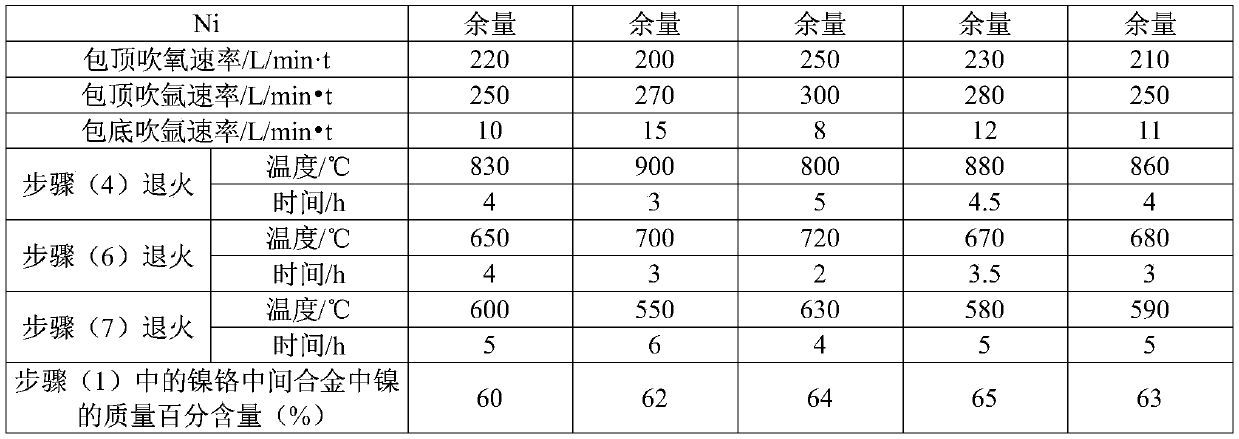

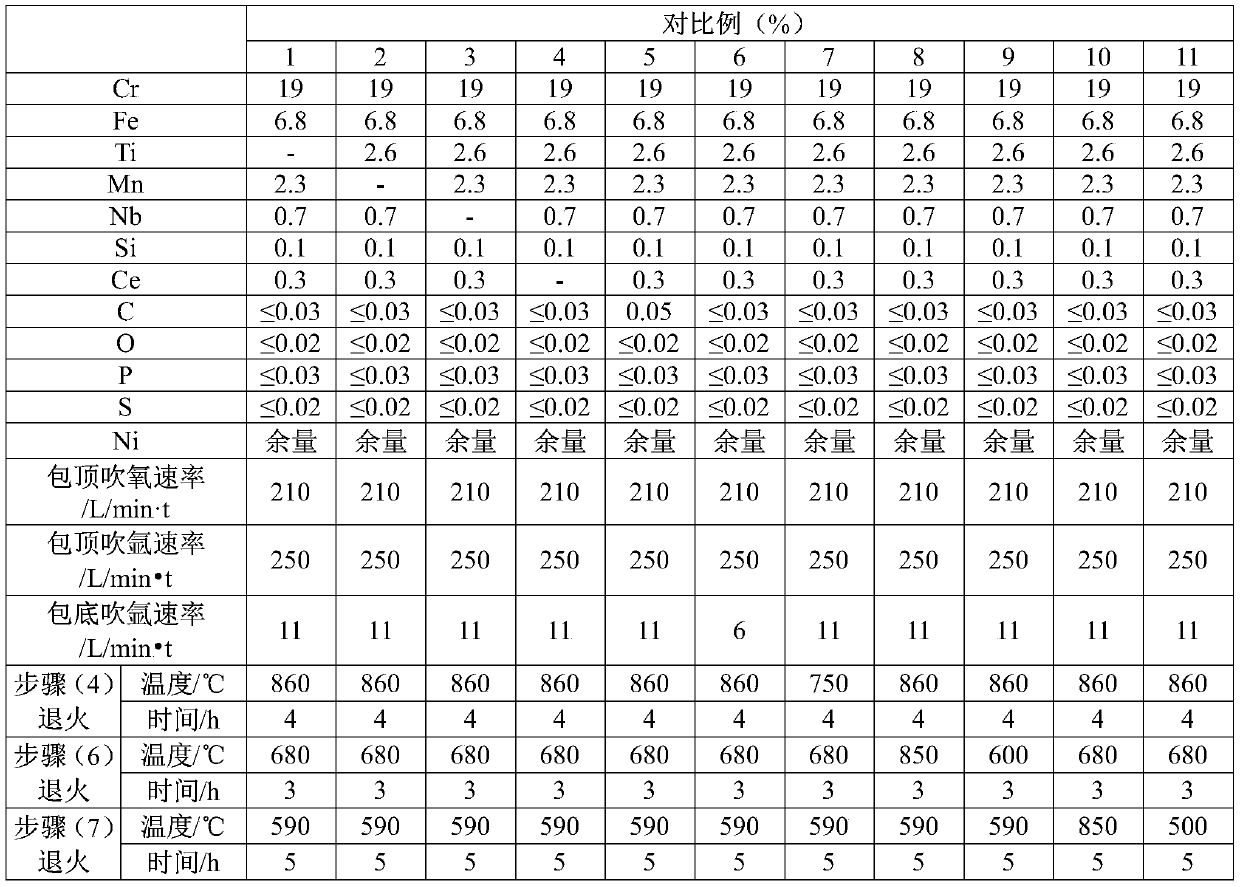

[0030] A preparation method for a nickel-based high-temperature-resistant and corrosion-resistant welding wire comprises the following steps:

[0031] (1) Raw materials are prepared in proportion, among which chromium and part of nickel are prepared in the form of nickel-chromium master alloy, other raw materials except titanium, chromium and part of nickel are added to the vacuum induction furnace for melting, and argon gas is blown from the bottom of the ladle Carry out degassing and stirring, and after all the raw materials are melted, start blowing oxygen from the top of the ladle for decarburization;

[0032] (2) After blowing oxygen at the top of the ladle for 20-30 minutes, add titanium and nickel-chromium master alloy to melt and disperse them. When the C content drops below 0.03%, stop blowing oxygen and blow argon from the top and bottom of the ladle simultaneously. ;

[0033] (3) Keep blowing argon at the bottom of the ladle, add ferrosilicon and aluminum blocks to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com