A kind of yb for white light led 2+ Excited nitrogen oxide green fluorescent material and preparation method thereof

A green fluorescence and nitrogen oxide technology, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of inapplicable nitrogen oxide stable production, unsuitable for market-oriented batch production, and affecting the commercialization process, etc. , to achieve the effects of large-scale production, green and environmentally friendly synthesis process, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

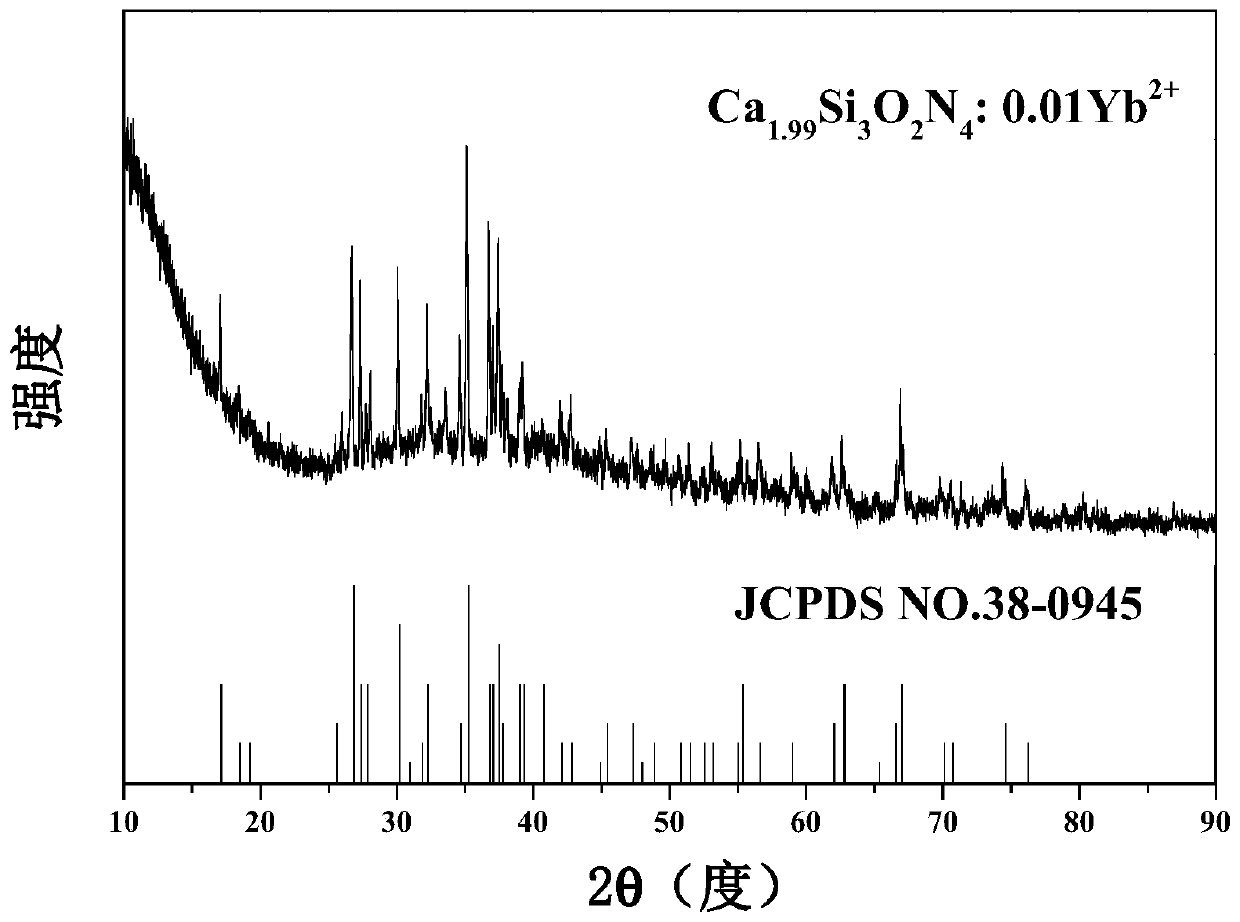

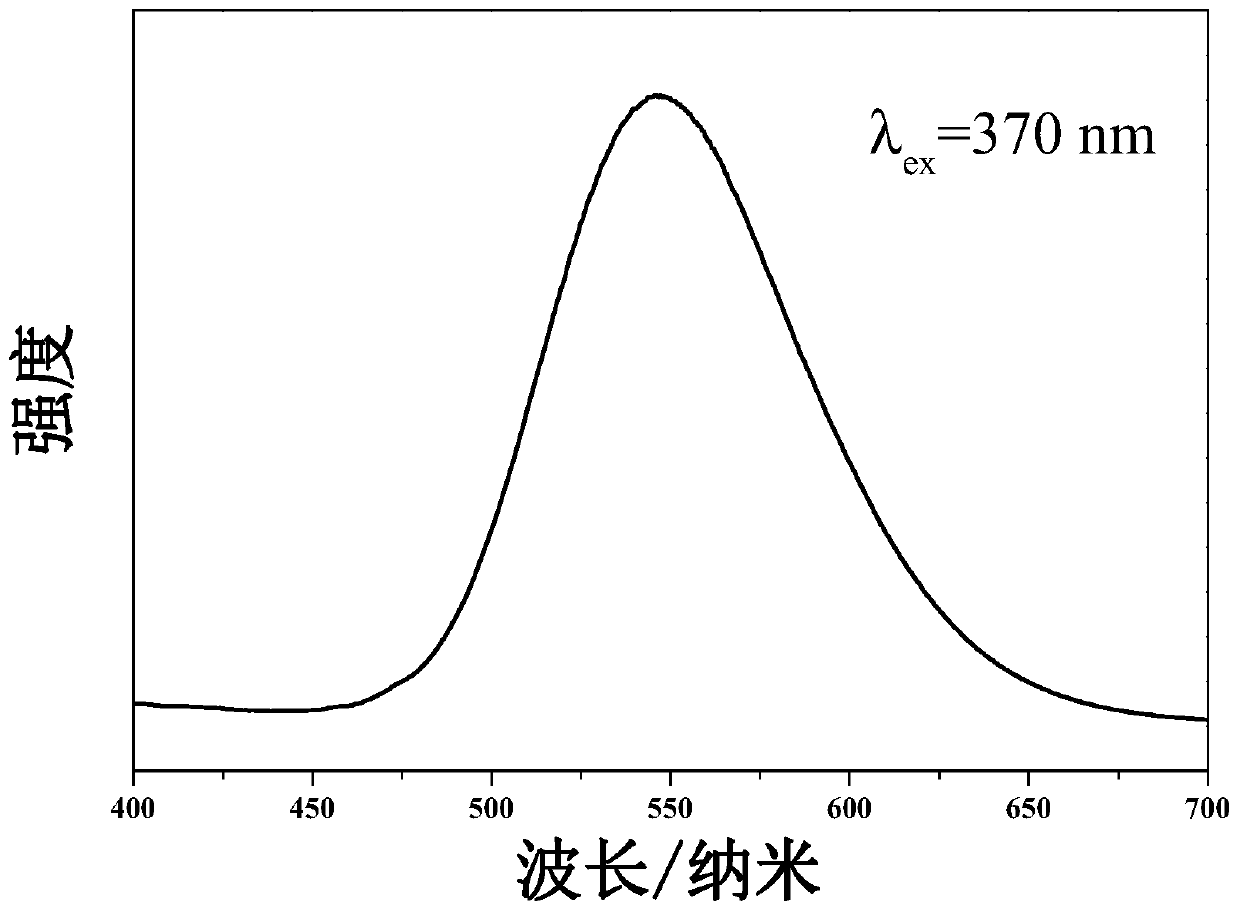

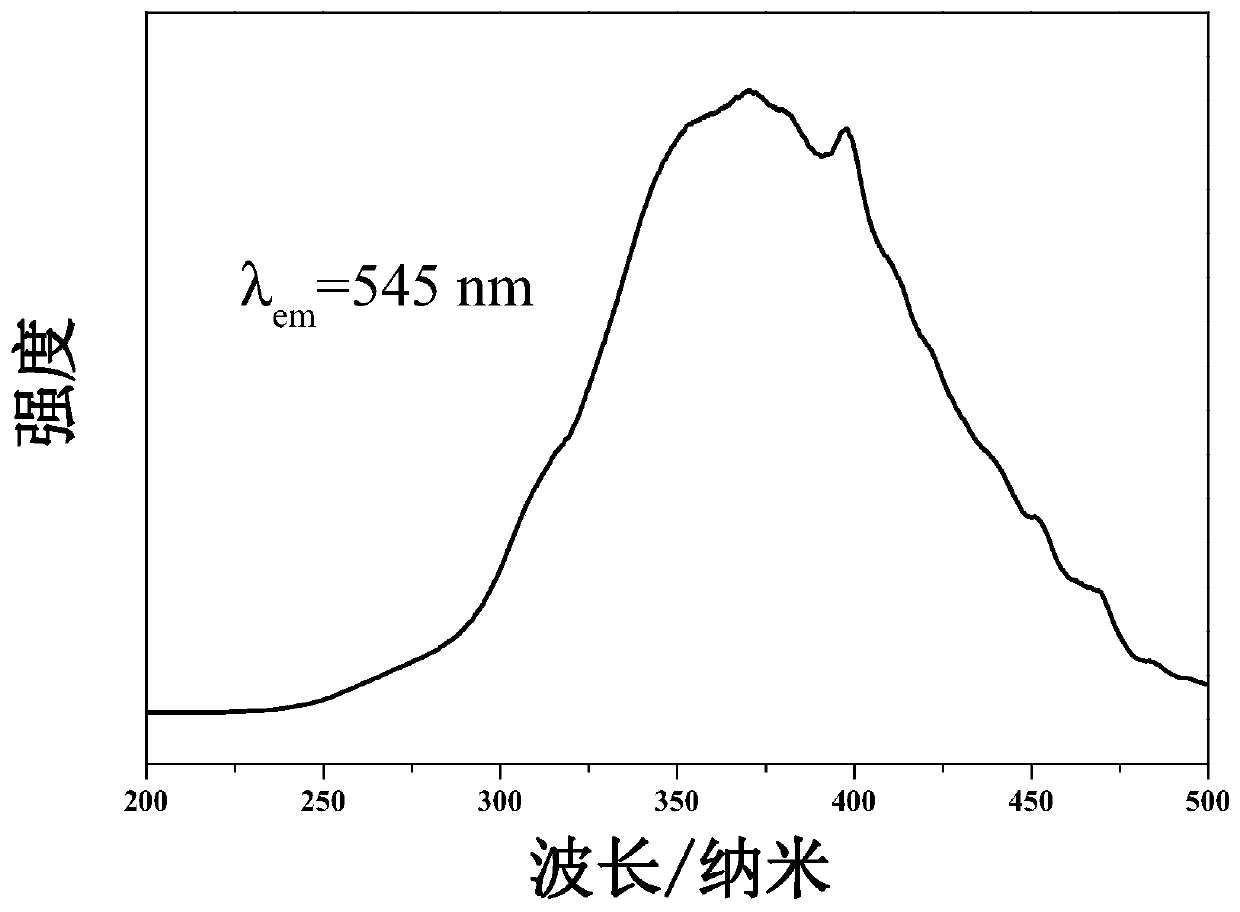

Embodiment 1

[0037] According to the chemical molar ratio of 2.985:2:0.0075, accurately weigh 0.39835g CaCO 3 , 0.30674g NH 4 h 2 PO 4 and 0.00394g Yb 2 o 3 , mix the raw materials and add 1 mL of ethanol for trituration. After grinding evenly, add high-purity Al 2 o 3 The crucible was sintered in a tube furnace at 1200 °C for 2 h, cooled to room temperature and ground to obtain the precursor Ca 3-x (PO 4 ) 2 : 2x / 3Yb 3 + (x=0.01). The resulting precursor and 0.41333g Si 3 N 4 The powders were mixed, then put into an agate mortar and 1mL of ethanol was added for thorough grinding. The mixture obtained after grinding and drying was put into a high-purity graphite ark, kept and sintered in a high-temperature tube furnace at 1400 ° C for 5 h, and the gas flow rate was 400 mL / min. 2 / H 2 mixed gas. The nitrogen oxide green fluorescent material is obtained by grinding after being cooled to room temperature in the furnace.

Embodiment 2

[0039] According to the chemical molar ratio of 2.97:2:0.015, accurately weigh 0.39636g CaCO 3 , 0.30674g NH 4 h 2 PO 4 and 0.00788g Yb 2 o 3 , mix the raw materials and add 1 mL of ethanol for trituration. After grinding evenly, add high-purity Al 2 o 3 The crucible was sintered in a tube furnace at 1200 °C for 2 h, cooled to room temperature and ground to obtain the precursor Ca 3-x (PO 4 ) 2 : 2x / 3Yb 3+ (x=0.02). The resulting precursor and 0.41333g Si 3 N 4 The powders were mixed, then put into an agate mortar and 1mL of ethanol was added for thorough grinding. The mixture obtained after grinding and drying was put into a high-purity graphite ark, kept and sintered in a high-temperature tube furnace at 1400 ° C for 5 h, and the gas flow rate was 400 mL / min. 2 / H 2 mixed gas. The nitrogen oxide green fluorescent material is obtained by grinding after being cooled to room temperature in the furnace.

Embodiment 3

[0041] According to the chemical molar ratio (2.955): 2:0.0225, accurately weigh 0.39435g CaCO 3 , 0.30674gNH 4 h 2 PO 4 and 0.01182g Yb 2 o 3 , mix the raw materials and add 1 mL of ethanol for trituration. After grinding evenly, add high-purity Al 2 o 3 The crucible was sintered in a tube furnace at 1200 °C for 2 h, cooled to room temperature and ground to obtain the precursor Ca 3-x (PO 4 ) 2 :2x / 3Yb 3+ (x=0.03). The resulting precursor and 0.41333g Si 3 N 4 The powders were mixed, then put into an agate mortar and 1mL of ethanol was added for thorough grinding. The mixture obtained after grinding and drying was put into a high-purity graphite ark, kept and sintered in a high-temperature tube furnace at 1400 ° C for 5 h, and the gas flow rate was 400 mL / min. 2 / H 2 mixed gas. The nitrogen oxide green fluorescent material is obtained by grinding after being cooled to room temperature in the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com