High-efficiency and durable exhaust gas degradation material and preparation method thereof

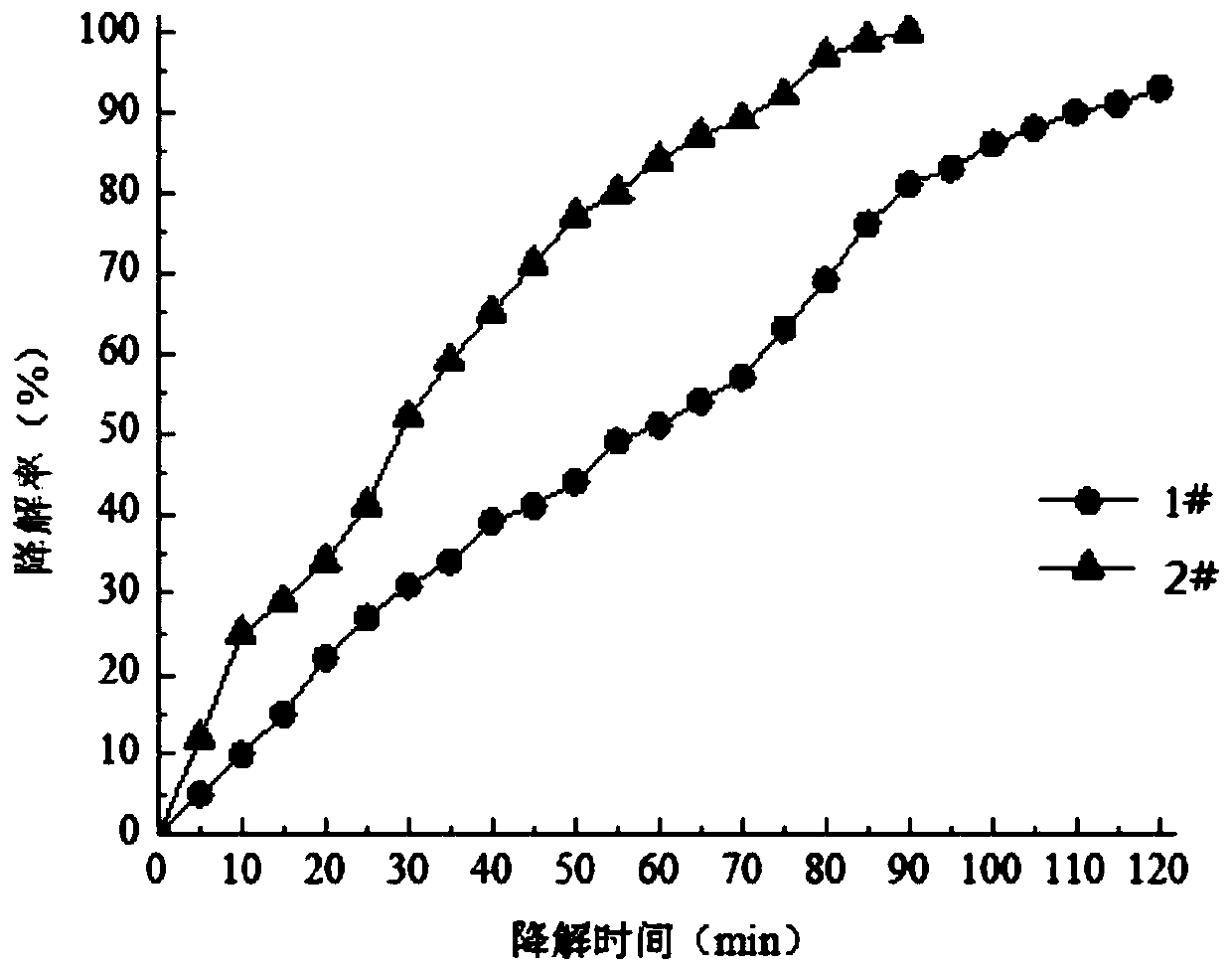

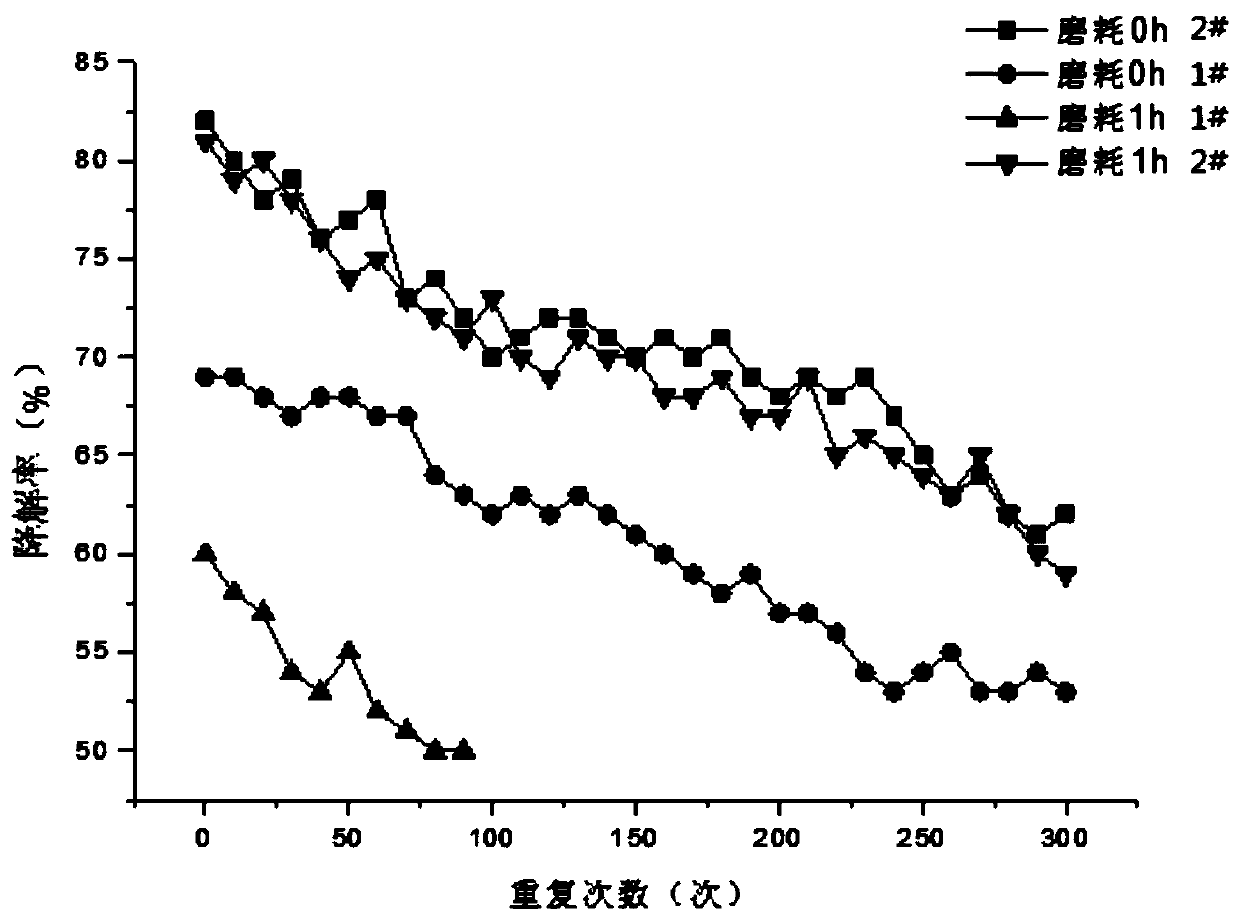

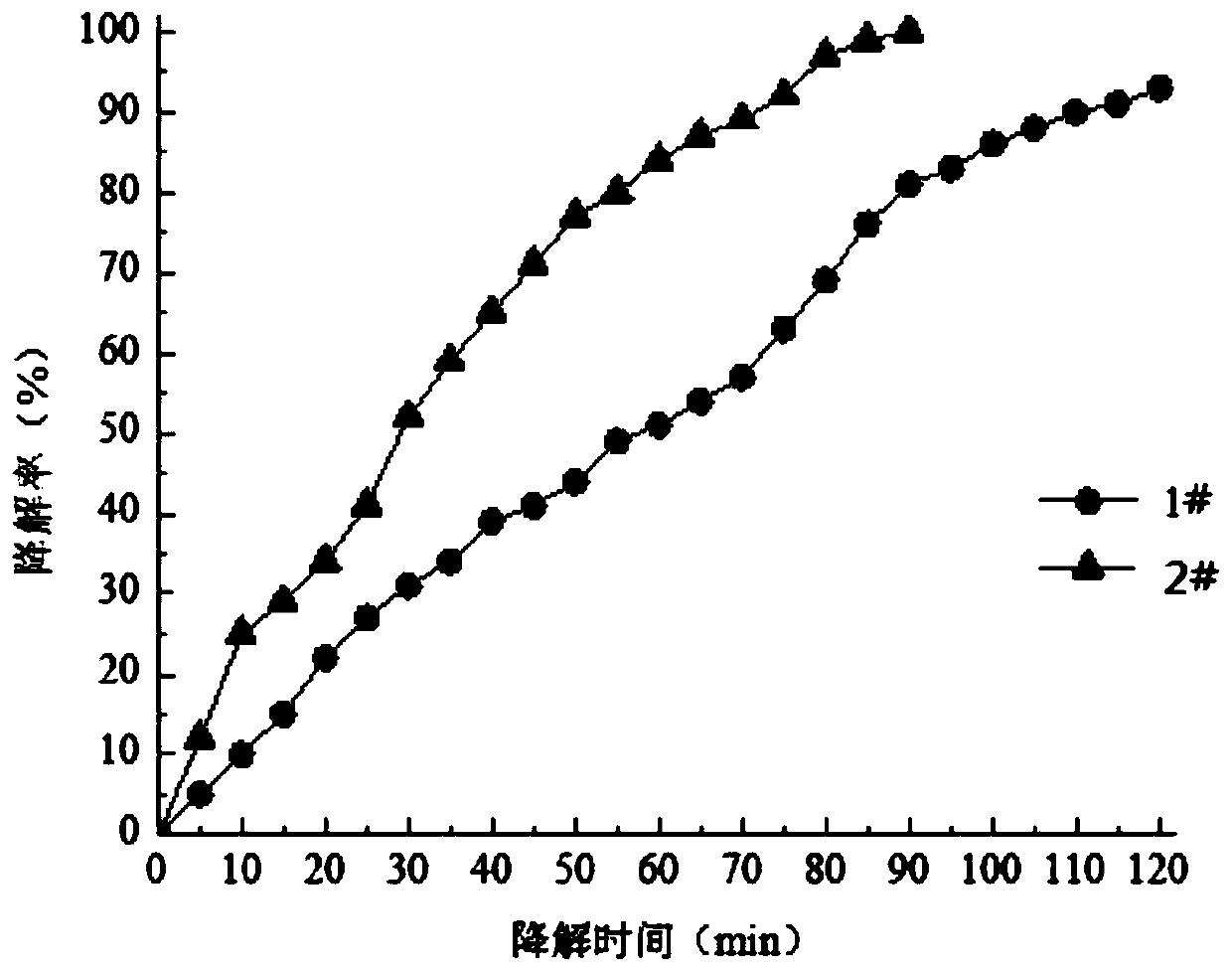

An exhaust gas degradation and durability technology, applied in unspecified rubber coatings, coatings, etc., can solve the problems of poor durability and low exhaust gas degradation efficiency, and achieve the effect of maintaining performance, improving wear resistance, and uniform particle distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An efficient and durable exhaust gas degradation material, including the following components by mass ratio: 45% nano-TiO 2 , 45% Al 2 o 3 and 10% rubber powder. The specific preparation method is as follows:

[0033] (1) Preparation of nano-TiO by sol-gel method 2 / Al 2 o 3 Composite carrier: according to the formula ratio, first dissolve tetra-n-butyl titanate in absolute ethanol (dispersant), the molar ratio of tetra-n-butyl titanate to dispersant is 1:10, then add 20% glacial acetic acid ( hydrolysis inhibitor), the molar ratio of tetra-n-butyl titanate to hydrolysis inhibitor is 1:1, stir to form a colloidal solution, then add deionized water, the molar ratio of tetra-n-butyl titanate to deionized water is 1 :4, while adding Al 2 o 3 , stir evenly to form a gel; dry the gel in a constant temperature oven at 100±5°C for 24 hours to obtain crystals, and place the prepared crystals in a muffle furnace at 500°C for 5 hours to obtain nano-TiO 2 / Al 2 o 3 Comp...

Embodiment 2

[0037] An efficient and durable exhaust gas degradation material, including the following components by mass ratio: 45% nano-TiO 2 , 43%Al 2 o 3 and 12% rubber powder. The specific preparation method is as follows:

[0038] (1) Preparation of nano-TiO by sol-gel method 2 / Al 2 o 3 Composite carrier: according to the formula ratio, first dissolve tetra-n-butyl titanate in isopropanol (dispersant), the molar ratio of tetra-n-butyl titanate to dispersant is 1:5, then add 20% glacial acetic acid ( hydrolysis inhibitor), the molar ratio of tetra-n-butyl titanate to hydrolysis inhibitor is 1:1, stir to form a colloidal solution, then add deionized water, the molar ratio of tetra-n-butyl titanate to deionized water is 1 :3, while adding Al 2 o 3 , stir evenly to form a gel; dry the gel in a constant temperature oven at 100±5°C for 24 hours to obtain crystals, and place the prepared crystals in a muffle furnace at 500°C for 5 hours to obtain nano-TiO 2 / Al 2 o 3 Composite c...

Embodiment 3

[0042] An efficient and durable exhaust gas degradation material, including the following components by mass ratio: 40% nano-TiO 2 , 48% Al 2 o 3 and 12% rubber powder. The specific preparation method is as follows:

[0043] (1) Preparation of nano-TiO by sol-gel method 2 / Al 2 o 3 Composite carrier: according to the formula ratio, first dissolve tetra-n-butyl titanate in n-butanol (dispersant), the molar ratio of tetra-n-butyl titanate to dispersant is 1:15, then add 20% glacial acetic acid ( hydrolysis inhibitor), the molar ratio of tetra-n-butyl titanate to hydrolysis inhibitor is 1:2, stir to form a colloidal solution, then add deionized water, the molar ratio of tetra-n-butyl titanate to deionized water is 1 :5, while adding Al 2 o 3 , stir evenly to form a gel; dry the gel in a constant temperature oven at 100±5°C for 24 hours to obtain crystals, and place the prepared crystals in a muffle furnace at 500°C for 5 hours to obtain nano-TiO 2 / Al 2 o 3 Composite c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com