Preparation of Ni-pillared manganese-based montmorillonite (Ni/Mn-MMT) low-temperature denitration catalyst

A low-temperature denitrification and montmorillonite technology, applied in the field of flue gas denitrification, can solve the problems of widening interlayer spacing, poor stability, small specific surface area, etc., and achieve the effects of low-temperature denitrification rate improvement, good low-temperature activity, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Take 20 g of purified montmorillonite, swell it with 1000 mL of deionized water for 6 h, and then take Ni(CH 3 COO) 2 4H 2 O solid, dissolved with appropriate amount of distilled water and added to montmorillonite with sufficient swelling, heated and stirred at 180 °C for 6 h, after the stirring was completed, move the suspension into a high-pressure reactor, and react at 180 °C for 5 h Then take it out and wash it by centrifugation for 3-4 times. After drying in an oven at 100 °C, it was baked in a muffle furnace at 500 °C for 4 hours to obtain nickel-based pillared montmorillonite (5%Ni-MMT). Ni / Mn-MMT catalysts were prepared by isometric impregnation method. Weigh 15 g of montmorillonite carrier, manganese load 15% (mass fraction), the required mass of MnSO 4 · H 2 O and the same molar ratio of (NH 4 ) 2 S 2 o 8 Dissolve in appropriate amount of distilled water. The prepared solution was added to the nickel-based pillared montmorillonite, heated and sti...

Embodiment 2

[0022] Ni(CH 3 COO) 2 4H 2 O solid, all the other steps are with embodiment 1, promptly obtain 10%Ni / Mn-MMT catalyst.

Embodiment 3

[0024] Ni(CH 3 COO) 2 4H 2 O solid, all the other steps are with embodiment 1, promptly obtain 15%Ni / Mn-MMT catalyst.

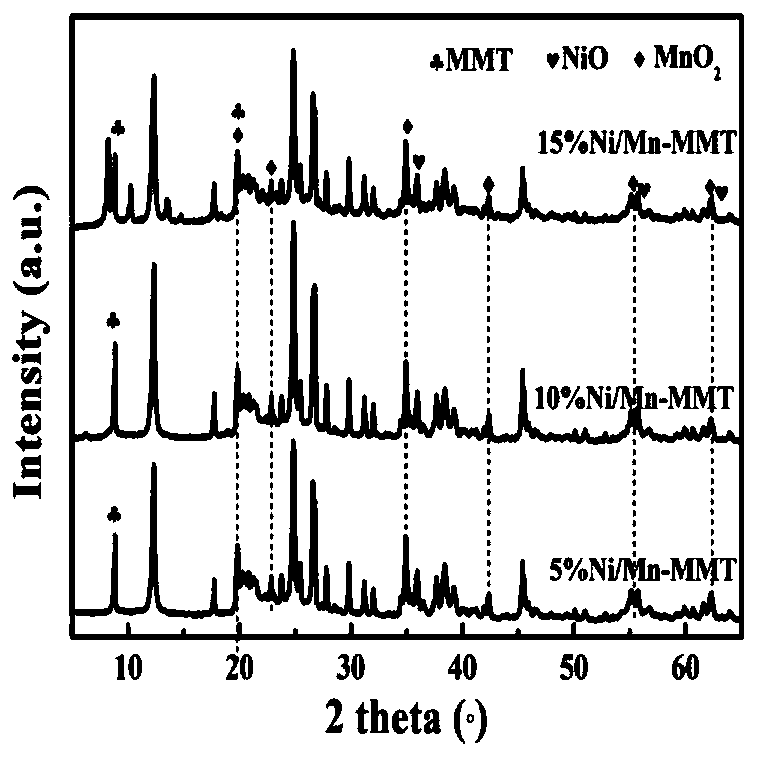

[0025] figure 1 It is the XRD figure of the Ni / Mn-MMT catalyst prepared in embodiment 1. It can be seen from the figure that in 2 θ The peak at 19.9º belongs to the (100) crystal plane, which is a characteristic peak of montmorillonite. None of the peaks changed after impregnation with the impregnation solution, indicating that the loaded active ingredient did not affect the structure of the carrier. at 2 θ =37.2°, 43.2°, 62.8° NiO diffraction peaks were detected, corresponding to (111), (200), (220) crystal planes of NiO, and at the same time at 2 θ =19.86°, 22.82°, 35.04°, 42.42°, 5.84°, 62.36° observed MnO 2 The peaks correspond to (100), (110), (040), (140), (240), (151) crystal planes, indicating that Ni and Mn are well pillared between the montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com