Arc ion plating adopting composite filtering of combined magnetic field, lined straight pipe and multihole baffle

The technology of arc ion plating and porous baffle plate is applied in the field of arc ion plating, which can solve the problems of vacuum chamber space and deposition position limitation, low arc plasma transmission efficiency, limitation of target element use, etc., so as to achieve effective control and improve Effectiveness of utilization efficiency, arc reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

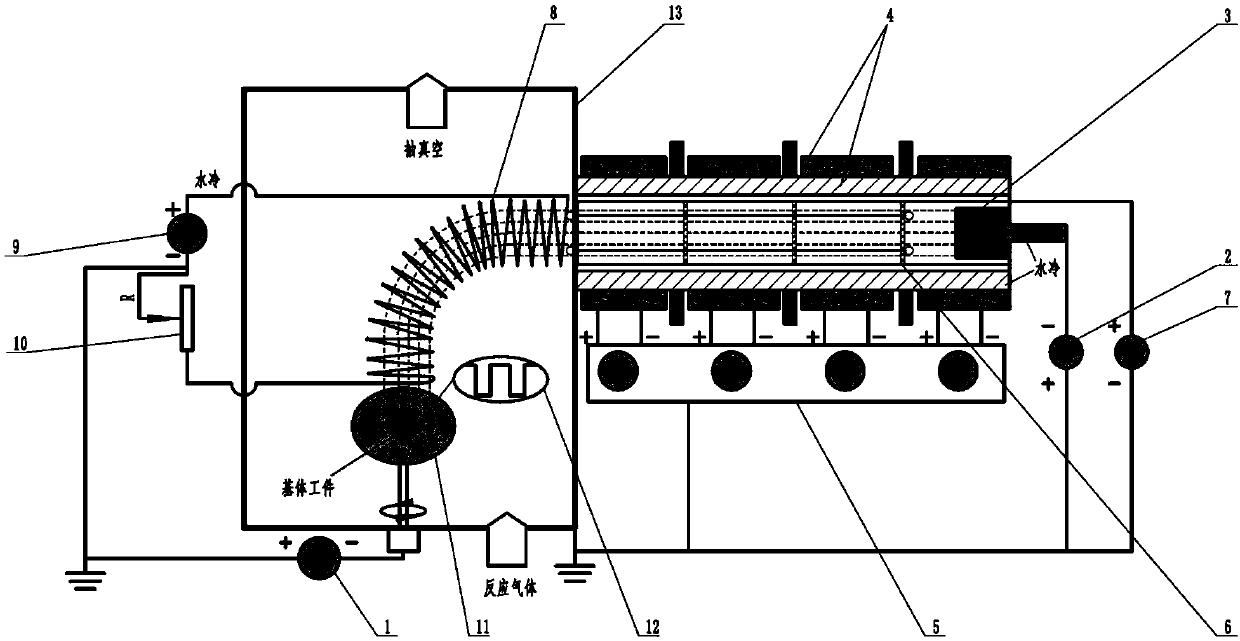

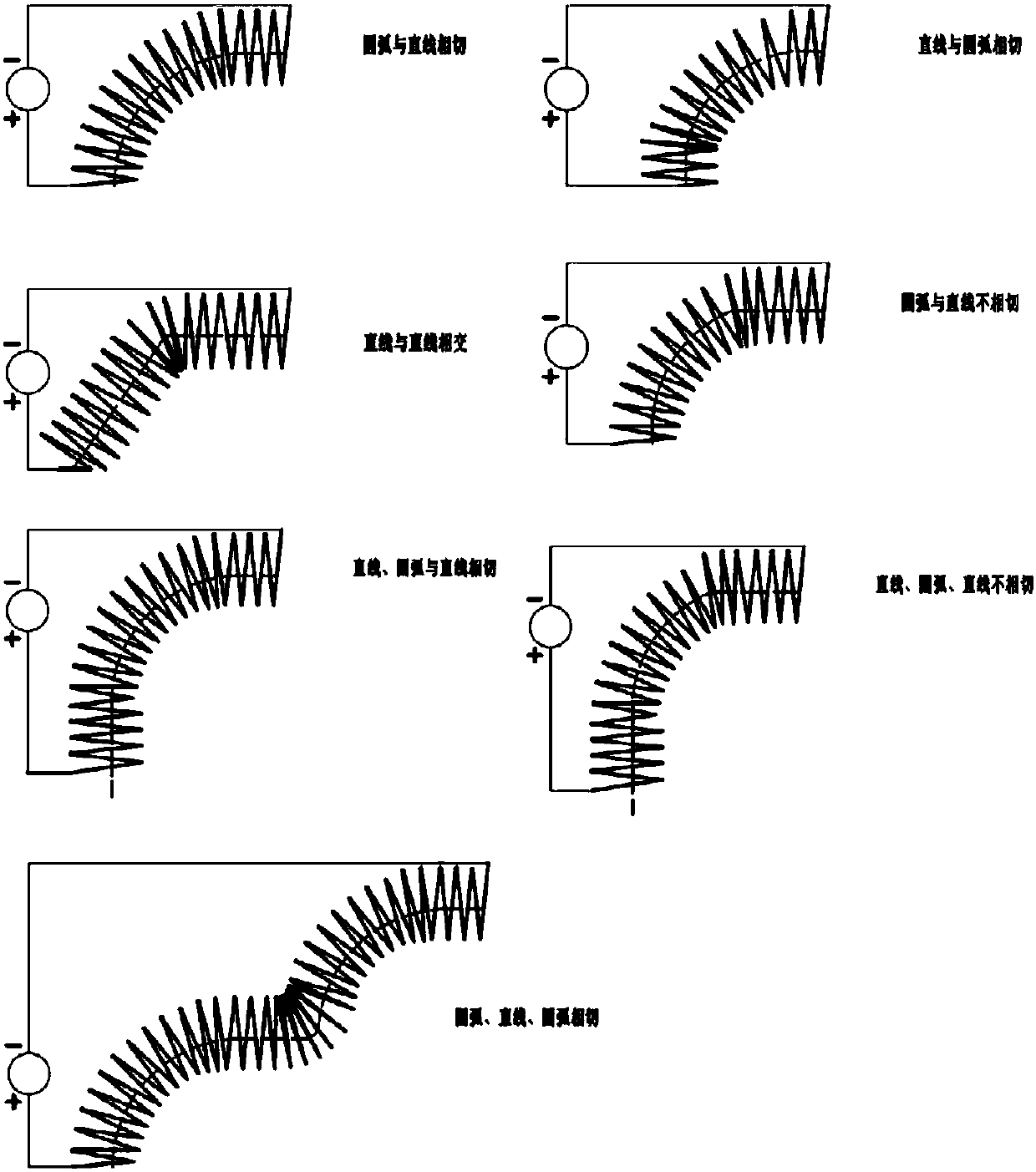

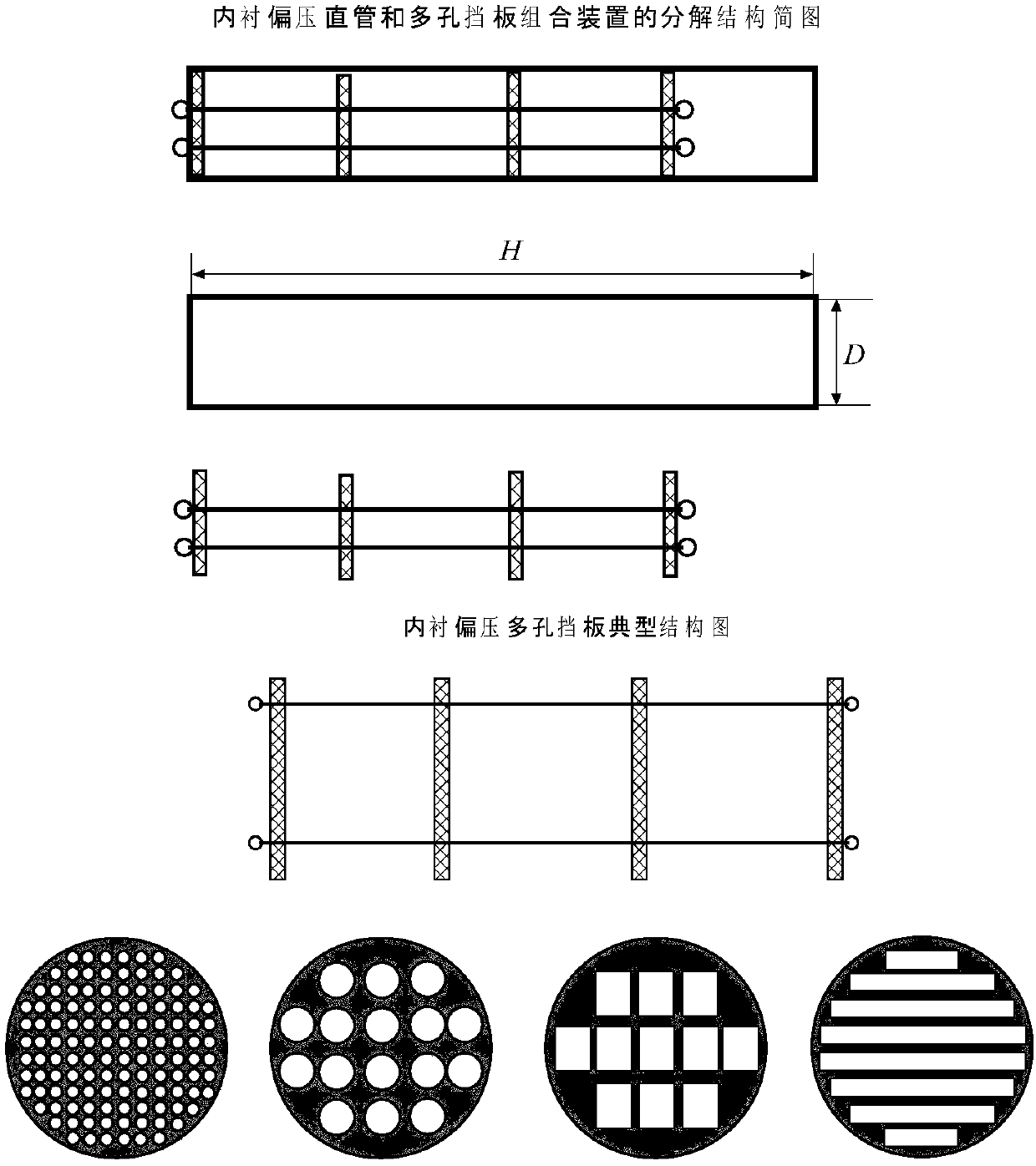

[0020] Specific implementation mode one: the following combination figure 1 , 2 and 3 illustrate the present embodiment, the present embodiment combines the magnetic field and the arc ion plating of the liner straight pipe and the porous baffle compound filter, and the device used includes the bias power supply (1), the arc power supply (2), the arc ion plating target source ( 3), multi-level magnetic field device (4), multi-level magnetic field power supply (5), liner bias straight tube and porous baffle combined device (6), liner bias power supply (7), movable coil device (8) , a movable coil device power supply (9), a rheostat device (10), a sample stage (11), a bias power supply waveform oscilloscope (12) and a vacuum chamber (13);

[0021] In this device:

[0022] The substrate workpiece to be processed is placed on the sample stage (11) in the vacuum chamber (13), the multi-stage magnetic field device (4), the combination device of the lined bias straight tube and the ...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the device can also realize other functions: it can combine traditional DC magnetron sputtering, pulse magnetron sputtering, traditional arc ion plating and pulse cathode arc Combination of one or more than two methods, and then apply DC bias, pulse bias, DC pulse composite bias or bipolar pulse bias device on the workpiece for thin film deposition to prepare pure metal thin films and compounds with different element ratios Ceramic films, functional films and high-quality films with nano-multilayer or gradient structures.

specific Embodiment approach 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the combined magnetic field is connected to the arc ion plating of the liner straight pipe and the porous baffle composite filter, the arc power supply (2) is turned on, and the multi-stage magnetic field power supply ( 5) Adjust the multi-stage magnetic field device (4), turn on the lining bias power supply (7), the liner bias straight tube and porous baffle combination device (6) maintain the DC positive bias, turn on the bias power supply (1), Turn on the power supply of the movable coil device (9), adjust the movable coil device (8), adjust the output resistance of the rheostat device (10), adjust the process parameters, and perform film deposition to prepare multilayer structure films with different stress states, microstructures and element ratios , and the others are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com