Stainless steel acid pickling sludge briquette, as well as preparation method and application thereof

A technology for pickling sludge and stainless steel is applied in the field of stainless steel pickling sludge briquetting and its preparation. , protect the environment, increase the effect of lime consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

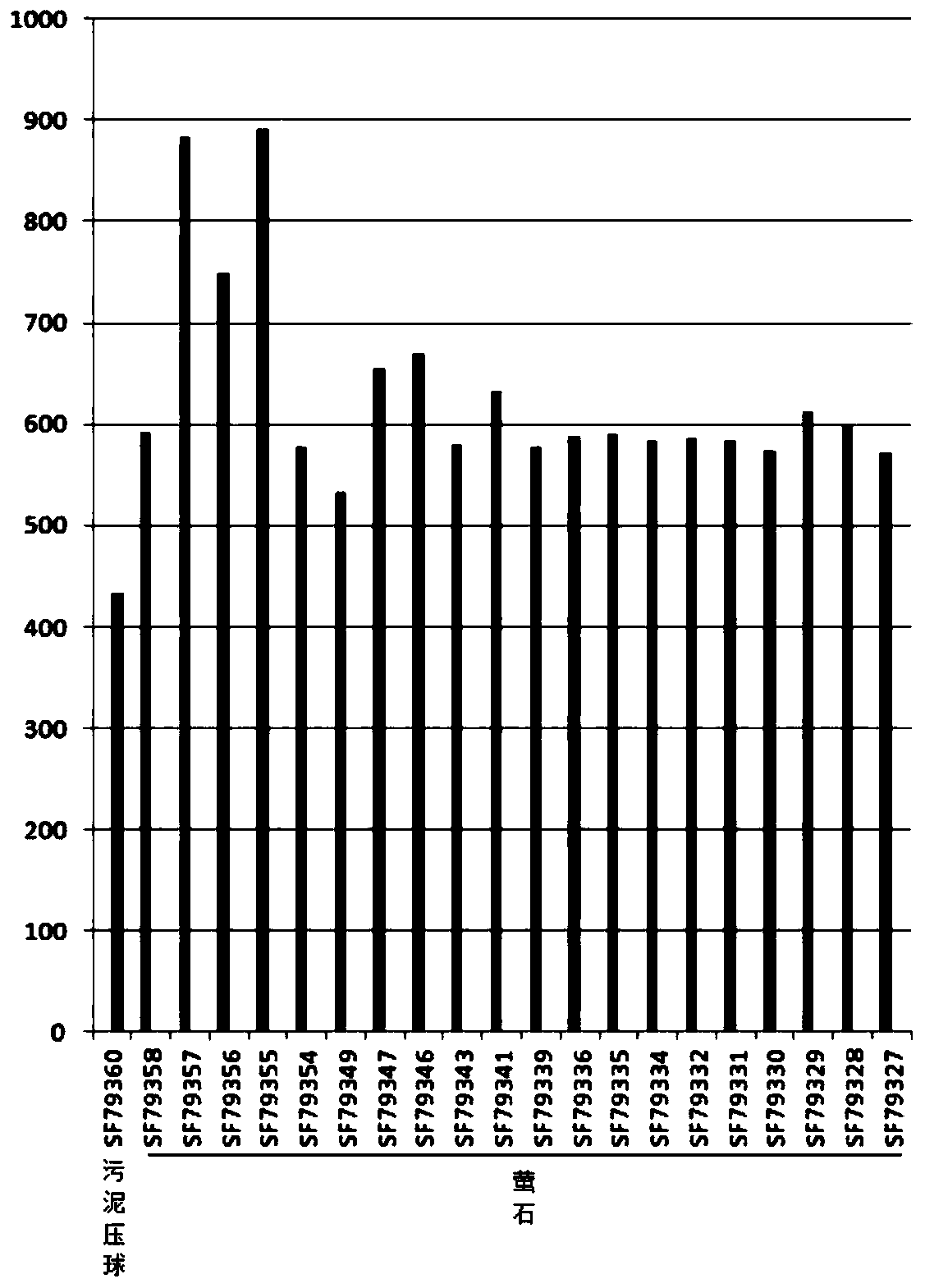

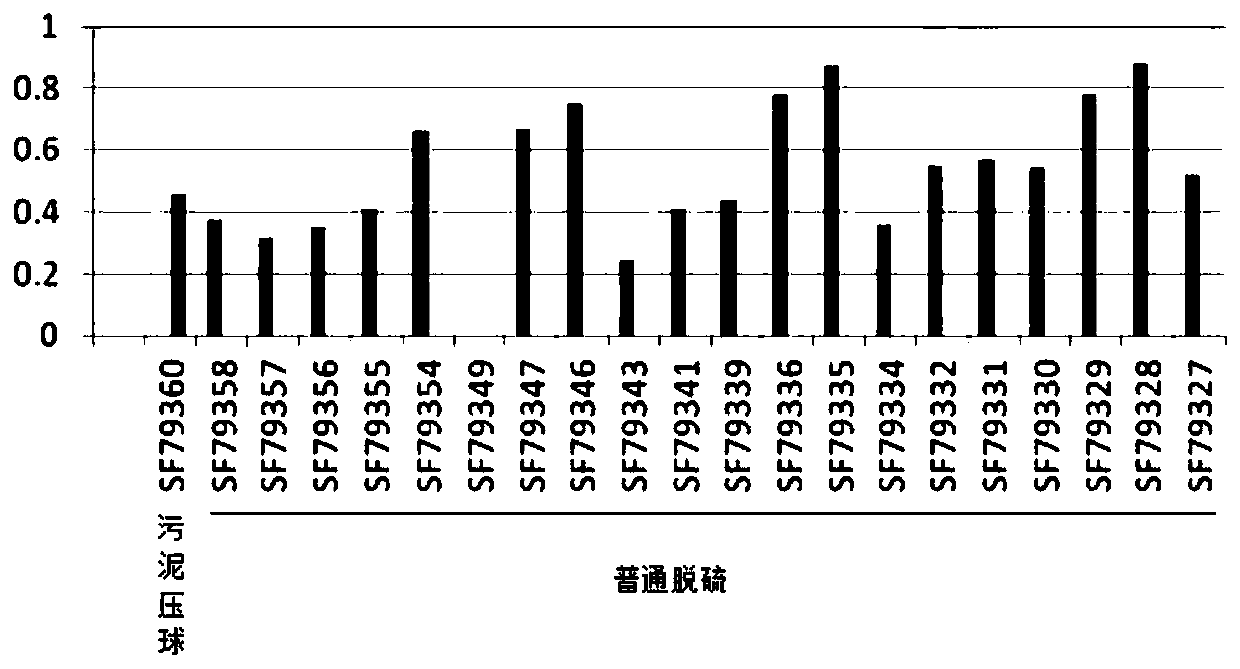

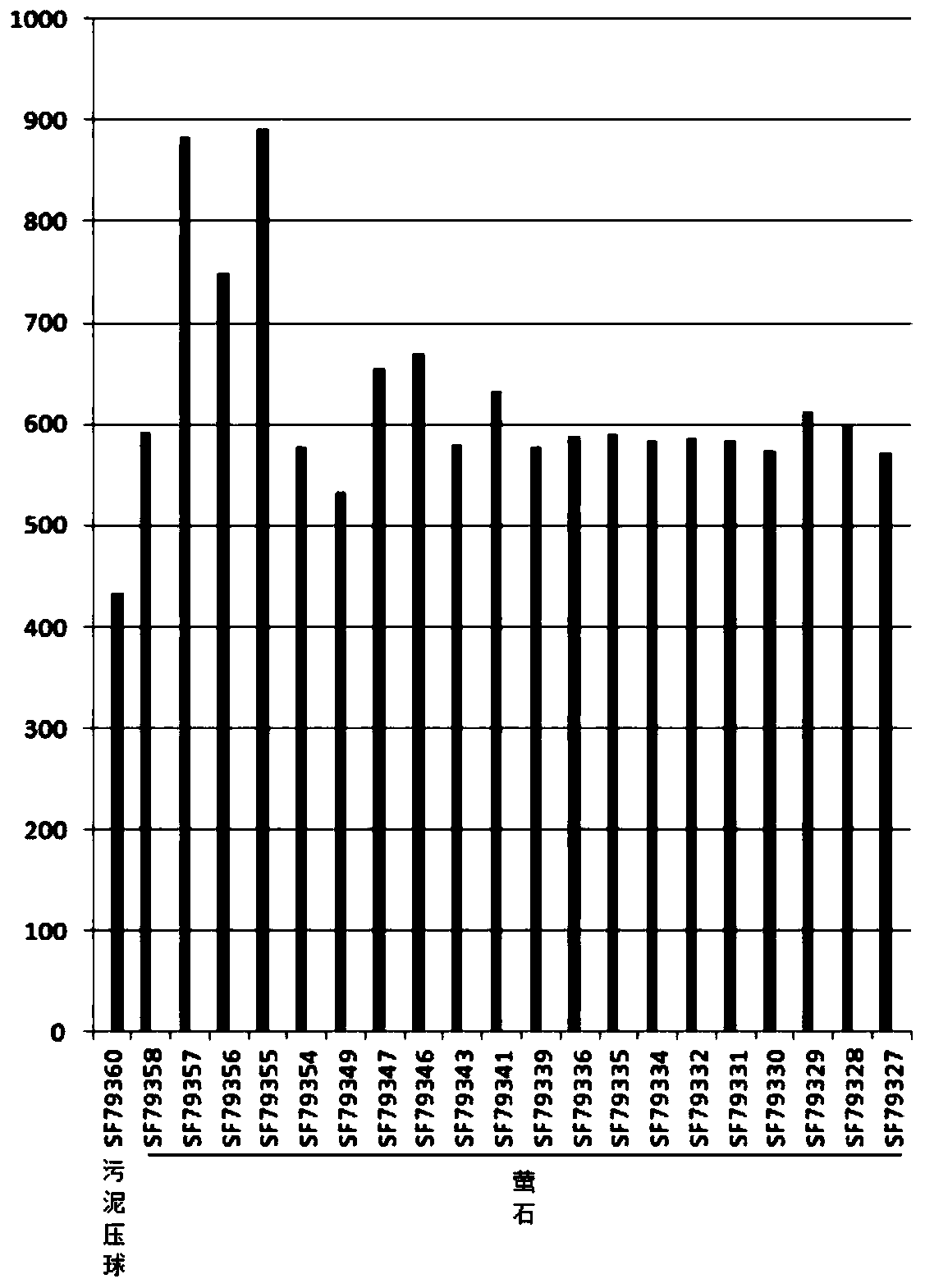

[0027] A stainless steel pickling sludge pressure ball, characterized in that its components include, by weight, 70-80 parts of stainless steel pickling sludge, 20-30 parts of framework material, and 2-5 parts of composite cellulose binder , the water content of the pressed ball is ≤5%, and the strength is ≥100kgf. The skeleton material is silicon carbide, which improves the strength of the pressure ball and increases the contact specific surface area between silicon carbide and stainless steel pickling sludge oxide; the particle size of silicon carbide is 1-2 mm.

[0028] Above-mentioned stainless steel pickling sludge pressure ball is made according to the following steps:

[0029] S1. Pressure filtration and drying: The stainless steel pickling sludge is subjected to pressure filtration and steam drying, so that the water content of the stainless steel pickling sludge is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com