Radiation cooling coating as well as preparation method and application thereof

A technology of coatings and reflective materials, applied in the direction of reflection/signal coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of inability to maintain radiation cooling for a long time, achieve low cost, broad application prospects, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 95 parts of absolute ethanol, 5 parts of deionized water, and 15 parts of polyvinyl butyral (Qingdao Haocheng Industry, SD-5) into the high-speed disperser, and stir for 120 minutes at a linear speed of 5 m / s to obtain a slurry material. Then add 20 parts of sodium zinc phosphate (1-3 μm), 30 parts of silicon dioxide (1-3 μm), 2 parts of trimethoxysilane dispersant, 1 part of dimethyl silicone oil defoamer, 1 part of inorganic silver-based antimicrobial agent (Beijing Eisel Technology Co., Ltd., MK-T-111), dispersed for 30 minutes, and filtered through a 100-mesh sieve to obtain the radiation cooling coating of the present invention.

Embodiment 2

[0034] Add 60 parts of cyclohexane, 30 parts of isopropanol, 10 parts of deionized water, and 20 parts of ethylene-vinyl acetate copolymer (Yangzi BASF, V5110J) into the high-speed disperser, and stir at a linear speed of 8 m / s After 20 minutes, the slurry was obtained. Then add 30 parts of zirconia (1~3μm), 10 parts of silicon dioxide (1~3μm), 2 parts of trimethoxysilane dispersant, 2 parts of dimethyl silicone oil defoamer at a speed of 5m / s, and disperse After 15 minutes, filter through an 80-mesh sieve to obtain the radiation cooling coating of the present invention.

Embodiment 3

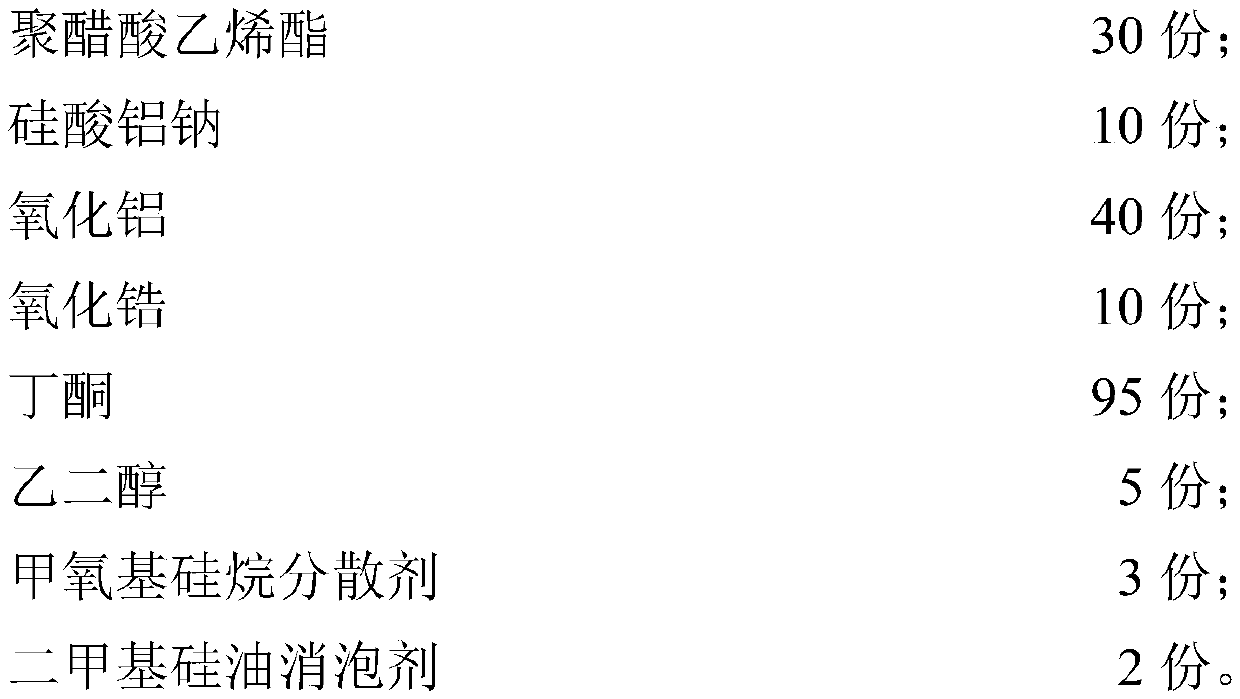

[0036] Add 95 parts of butanone, 5 parts of ethylene glycol, and 20 parts of polyvinyl acetate (Xiamen Chonghuayuan, PVAc-H) into the high-speed disperser, and stir for 60 minutes at a linear speed of 10 m / s to obtain a slurry. Then add 10 parts of sodium aluminum silicate (1-3 μm), 50 parts of aluminum oxide (1-3 μm), 3 parts of trimethoxysilane dispersant, and 2 parts of dimethyl silicone oil defoamer at a speed of 20 m / s. Disperse for 45 minutes and filter through an 80-mesh sieve to obtain the radiation cooling coating of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com