Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of insufficient depletion, devices that cannot provide high-level breakdown voltage, and limited optimization of gate polycrystalline boundary electric field and other issues to achieve the effect of increasing the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

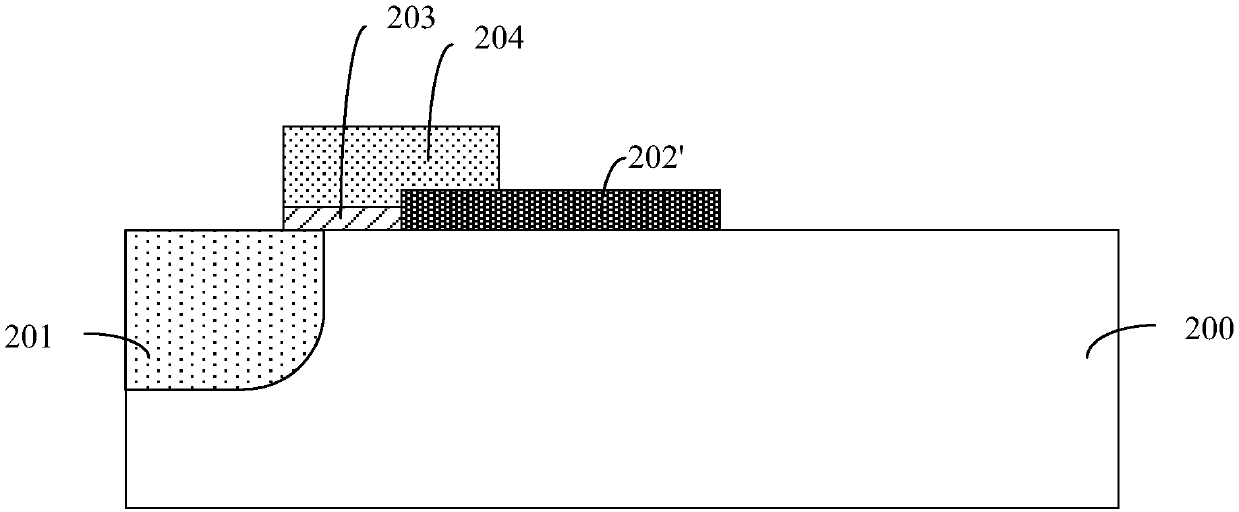

[0056] The invention provides a method for preparing a semiconductor device, such as figure 1 As shown, the main steps of the preparation method include:

[0057] Step S101: providing a semiconductor substrate formed with a body region, a gate dielectric layer and a field oxide layer;

[0058] Step S102: forming a gate poly, the gate poly covers the gate dielectric layer and the field oxide layer, and exposes at least part of the field oxide layer;

[0059] Step S103: using the drift region masking layer as a mask to form a drift region in the semiconductor substrate by ion implantation, continue to use the drift region masking layer as a mask to remove the exposed field oxide layer, and form a A first field oxygen of extremely polycrystalline self-alignment, the gate polycrystalline as a first field plate;

[0060] Step S104: forming a source region in the body region, and forming a drain region in the drift region;

[0061] Step S105: forming a second field oxygen on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com