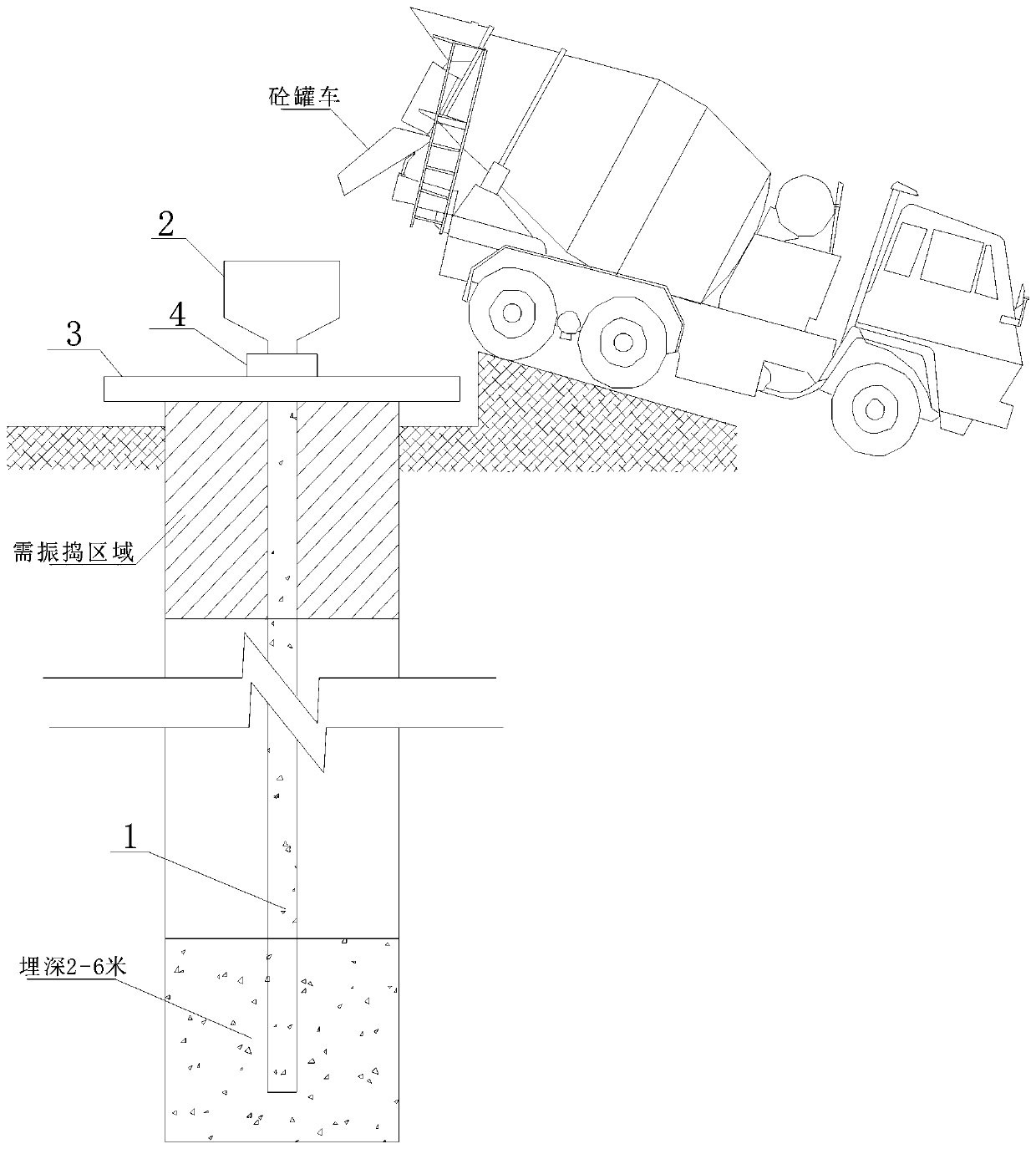

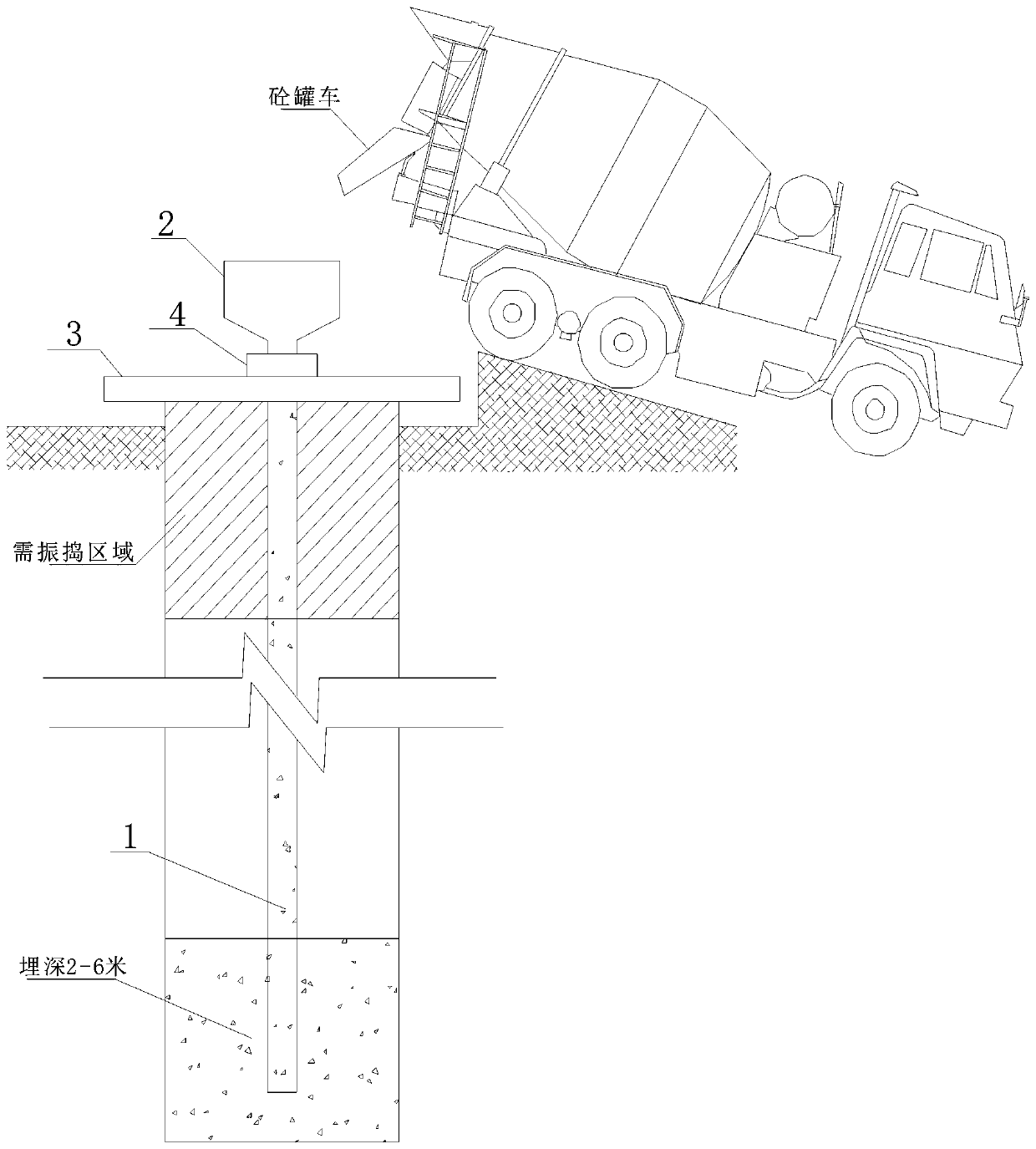

Pouring method of manual digging pile body concrete by using anhydrous underwater concrete pouring method

A technology for underwater concrete and artificial digging piles, which is applied in construction, infrastructure engineering and other directions, can solve the problems of pipe lifting and backflow, low construction efficiency, poor visibility, etc., to avoid safety accidents, high construction efficiency, The effect of less construction disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] Step 1: Mixing of concrete: The concrete used in the anhydrous underwater concrete pouring method has specific requirements. The concrete mix ratio should adopt the mix ratio of underwater concrete. The mix ratio of C30 concrete is: water (164kg): cement (320kg ): gravel (1047kg): sand (790kg): water reducing agent (3.6kg): fly ash (80kg). The design slump of concrete is 180~220mm;

[0027] Step 2: Concrete opening: when the first set of concrete is poured, the distance between the conduit opening and the bottom of the hole is 40~50cm, and the amount of concrete in the first set is calculated to ensure that the first set of concrete can allow the conduit to reach the required buried depth, and the concrete is continuously supplied;

[0028] Step 3: Normal pouring of concrete: The anhydrous underwater concrete pouring method mainly makes the concrete dense through the self-weight of the concrete, the downward impact of the concrete and the violent vibration of the condui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com