Fluorine-free antibacterial transparent superhydrophobic coating, preparation method and application thereof

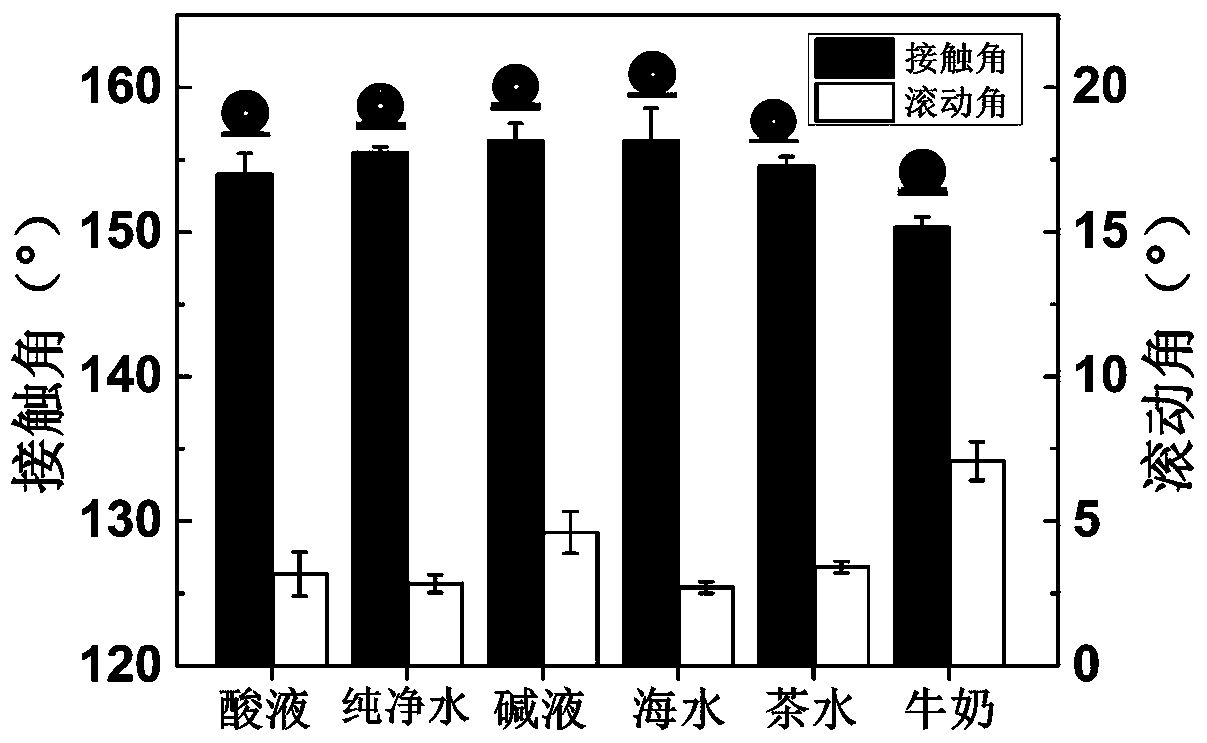

A super-hydrophobic coating, transparent technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the harsh conditions of the preparation method, complicated preparation process, and few reports on the stability of hydrophobic properties, etc. problems, achieve good mechanical/physical/chemical stability, excellent superhydrophobic performance and antibacterial performance, and ensure the effect of superhydrophobic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of fluorine-free antibacterial transparent super-hydrophobic coating specifically includes the following steps:

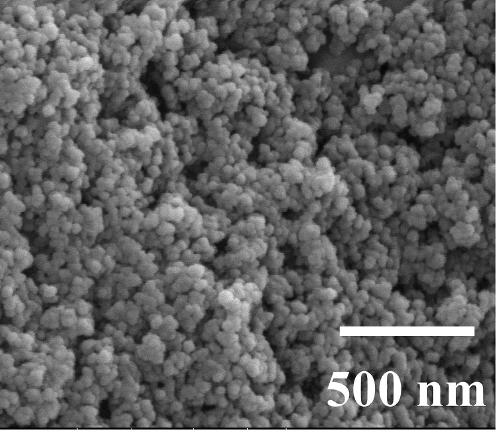

[0050] (1) Preparation of inorganic / organic nanoparticles modified with quaternary ammonium silane coupling agent: 0.5g of silica nanoparticles with a size of about 50 nanometers were dispersed in a mixed solution of 22g of water and 27.28g of absolute ethanol, and then Add 0.22g dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride, stir for 24h and then separate and wash to obtain silica nanometer modified by quaternary ammonium silane coupling agent Particles.

[0051] (2) Preparation of fluorine-free antibacterial transparent superhydrophobic coating: 0.2g of silica nanoparticles modified with quaternary ammonium salt silane coupling agent prepared in step (1) were dispersed into 150g of cyclohexane solution, and then added 0.2g of thermoplastic elastomer styrene-ethylene-butylene-styrene block copolymer (SEBS), mixed uniformly t...

Embodiment 2

[0055] A preparation method of fluorine-free antibacterial transparent super-hydrophobic coating specifically includes the following steps:

[0056] (1) Preparation of inorganic / organic nanoparticles modified by quaternary ammonium silane coupling agent: Disperse 0.05g of titanium dioxide nanoparticles with a size of about 200 nanometers into a mixed solution of 22g of water and 27.8g of absolute ethanol, and then add 0.15 g dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium bromide was stirred for 36h and then separated and washed to obtain titanium dioxide nanoparticles modified with quaternary ammonium silane coupling agent.

[0057] (2) Preparation of fluorine-free antibacterial transparent superhydrophobic coating: 0.0453g of quaternary ammonium salt-based silane coupling agent modified titanium dioxide nanoparticles prepared in step (1) were dispersed into 150.3237g cyclohexane solution, and then 0.031 was added g Thermoplastic elastomer styrene-ethylene-butylene-styrene bl...

Embodiment 3

[0061] A preparation method of fluorine-free antibacterial transparent super-hydrophobic coating specifically includes the following steps:

[0062] (1) Preparation of inorganic / organic nanoparticles modified by quaternary ammonium silane coupling agent: Disperse 1.5 g of silica nanoparticles with a size of about 900 nanometers into a mixed solution of 18 g of water and 23 g of absolute ethanol, and then add 3.5 g Dimethyltetradecyl[3-(trimethoxysilyl)propyl]ammonium chloride and 4g dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium bromide A mixed quaternary ammonium silane coupling agent is stirred for 32 hours and then separated and washed to obtain silica nanoparticles modified by the quaternary ammonium silane coupling agent.

[0063] (2) Preparation of fluorine-free antibacterial transparent superhydrophobic coating: 14.81g of silica nanoparticles modified with quaternary ammonium salt silane coupling agent prepared in step (1) were dispersed into 30.78g of methylene chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com