A method and device for emergency treatment of port ballast water with ultraviolet photocatalytic strong oxidation

An emergency treatment and ballast water technology, applied in the field of water treatment, can solve the problems such as the inability to meet the emergency rapid treatment of ballast water, high energy consumption, affecting the UV penetration rate, etc. , to ensure the effect of penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

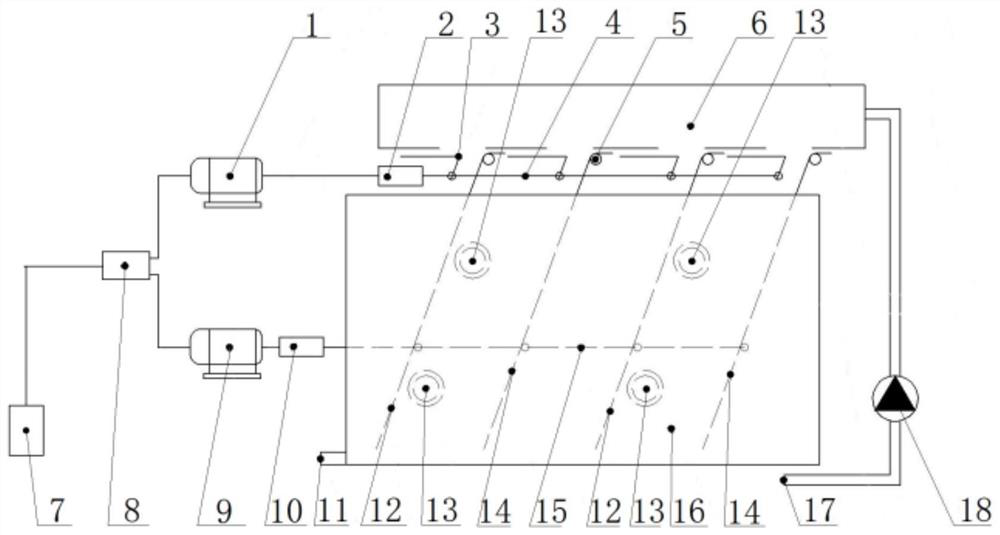

[0024] Select the thin steel plate as the ordinary fixed plate, and the other parts are as figure 1 shown in . Establish two quartz plates 12 and two thin steel plates 14, the size of the quartz plates 12 and the thin steel plates 14 is 1.5 meters long and 1 meter wide, and each quartz plate 12 is equipped with 15 36W ultraviolet lamps 13 with a wavelength of 254nm.

[0025] Step 1: Connect the water inlet pipe 17 to the ballast tank, start the pump 18 to pump the ballast water into the water tank 6, and the flow rate of the pump 18 is fixed at 600m 3 / h.

[0026] Step 2: Input 30° on the input device 7, and the Raspberry Pi 8 controls the second servo motor 9 to push the second slider 10, so that the inclination angle of the quartz plate 12 and the thin steel plate 14 is fixed at 30°.

[0027] Step 3: When the ballast water in the water tank 6 reaches a certain thickness, input 20mm in the input device 7, and the Raspberry Pi 8 controls the first servo motor 1 to push the f...

Embodiment 2

[0031] Select the thin steel plate as the ordinary fixed plate, and the other parts are as figure 1 shown in . Establish two quartz plates 12 and two thin steel plates 14, the size of the quartz plates 12 and the thin steel plates 14 is 1.5 meters long and 1 meter wide, and each quartz plate 12 is equipped with 15 36W ultraviolet lamps 13 with a wavelength of 254nm.

[0032] Step 1: Connect the water inlet pipe 17 to the ballast tank, start the pump 18 to pump the ballast water into the water tank 6, and the flow rate of the pump 18 is fixed at 200m 3 / h.

[0033] Step 2: Input 60° on the input device 7, and the Raspberry Pi 8 controls the second servo motor 9 to push the second slider 10, so that the inclination angle of the quartz plate 12 and the thin steel plate 14 is fixed at 60°.

[0034] Step 3: When the ballast water in the water tank 6 reaches a certain thickness, input 5mm in the input device 7, and the Raspberry Pi 8 controls the first servo motor 1 to push the fi...

Embodiment 3

[0038] Select the thin steel plate as the ordinary fixed plate, and the other parts are as figure 1 shown in . Establish two quartz plates 12 and two thin steel plates 14, the size of the quartz plates 12 and the thin steel plates 14 is 1.5 meters long and 1 meter wide, and each quartz plate 12 is equipped with 15 36W ultraviolet lamps 13 with a wavelength of 254nm.

[0039] Step 1: Connect the water inlet pipe 17 to the ballast tank, start the pump 18 to pump the ballast water into the water tank 6, and the flow rate of the pump 18 is fixed at 510m 3 / h.

[0040] Step 2: Input 45° on the input device 7, the Raspberry Pi 8 controls the second servo motor 9 to push the second slider 10, so that the inclination angle of the quartz plate 12 and the thin steel plate 14 is fixed at 45°.

[0041] Step 3: When the ballast water in the water tank 6 reaches a certain thickness, input 15mm in the input device 7, and the Raspberry Pi 8 controls the first servo motor 1 to push the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com