Additive capable of reducing CO in papermaking process reconstituted tobacco and application method of additive

A technology of reconstituted tobacco leaves and additives, applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of reducing sensory quality, insignificant effect, difficult process technology, etc., to achieve the reduction of CO emission, high method feasibility, and achievable degree high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Combine ammonium polyphosphate, sodium alginate, calcium carbonate, and potassium citrate, and add them to the coating solution of reconstituted tobacco leaves by papermaking method according to the proportion of the absolute dry weight of the finished product of reconstituted tobacco leaves by papermaking method. For the test, see Table 1. After the sample preparation process, the paper-making reconstituted tobacco samples with reduced CO were prepared and the sensory evaluation is shown in Table 2. The routine indicators of the measured smoke are shown in Table 3.

[0028] Table 1: Additive composition of coating fluid with 5 different additive formulas and their solubility in coating fluid

[0029]

[0030]

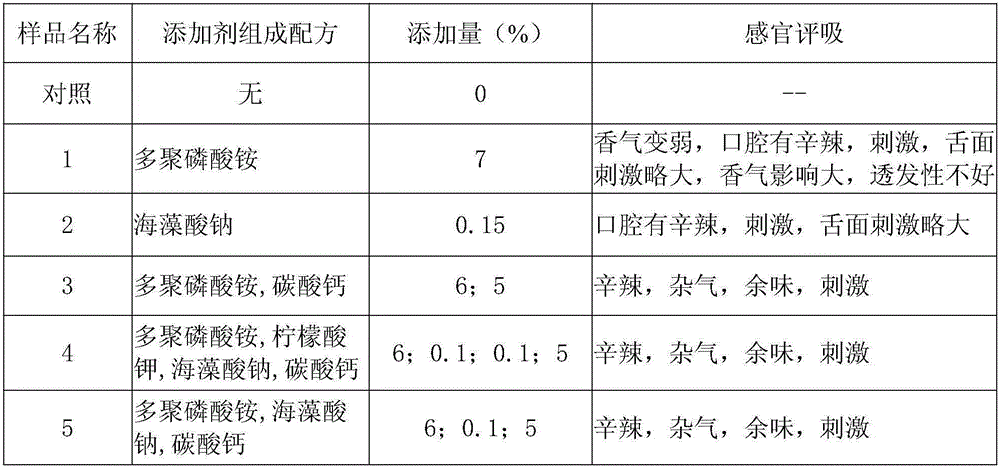

[0031] Table 2: Sensory evaluation results of reconstituted tobacco samples with 5 different additive formulations and papermaking methods

[0032]

[0033] Generally speaking, there are problems of pungentness, miscellaneous smell, aftertaste, and irri...

Embodiment 2

[0038] The CO reduction additives potassium dihydrogen phosphate, dipotassium hydrogen phosphate and sodium dihydrogen phosphate were tested as shown in Table 4, and added to the coating solution as shown in Table 4. After the sample preparation process, the papermaking reconstituted tobacco leaf sample with CO reduction was prepared. See Table 5, see Table 5 after sensory evaluation, and see Table 6 for conventional indicators of flue gas.

[0039] Table 4: Additive composition of different additive formulations and coating liquid additive composition and solubility with coating liquid

[0040]

[0041] Table 5: Sensory evaluation results of reconstituted tobacco samples with different additive formulations and papermaking methods

[0042]

[0043] These problems can be modified by flavoring, the style is consistent with the control, and the miscellaneous smell is not heavy; the sensory quality is ranked >7≥8>9 for the control.

[0044] Table 6: Determination of routin...

Embodiment 3

[0048]The CO reduction additives potassium dihydrogen phosphate, dipotassium hydrogen phosphate and sodium dihydrogen phosphate were tested as shown in Table 7, and added to the coating solution as shown in Table 7. After the sample preparation process, a papermaking reconstituted tobacco leaf sample with CO reduction was prepared. See Table 8, see Table 8 after sensory evaluation, and see Table 9 for conventional indicators of flue gas.

[0049] Table 7: Additive composition of coating fluid with different additive formulations and their solubility with coating fluid

[0050]

[0051]

[0052]

[0053] Table 8: Sensory evaluation results of reconstituted tobacco samples with different additive formulations and papermaking methods

[0054]

[0055] These problems can be modified by spices. According to the test results of smoke indicators and process tests, the sensory quality of No. 13, No. 18 and No. 25 is selected to be closer to the control.

[0056] Table 9: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com