Paint surface protective wax

A technology for protecting wax and paint surfaces, applied in wax physical treatment, chemical/physical/physicochemical mobile reactors, chemical/physical/physicochemical processes, etc. Insufficient weather resistance and other problems, to achieve good anti-corrosion effect, reduce pollution, and long protection period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

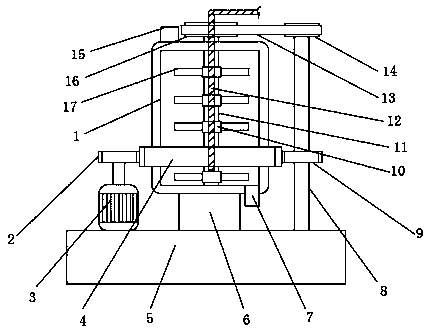

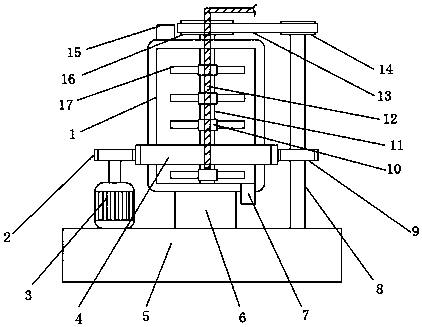

[0029] see figure 1 Shown, a kind of paint protective wax, this protective wax is prepared by following raw material: 15 parts of paraffin wax, 15 parts of microcrystalline wax, 3 parts of corrosion inhibitor, 30 parts of composite emulsifier, 5 parts of antioxidant, 20 parts of kaolin, 30 parts of environmental protection resin, 2 parts of sodium dodecylbenzenesulfonate;

[0030] Wherein, the protective wax is prepared through the following steps:

[0031] Step 1. Put the weighed paraffin wax and microcrystalline wax into the reaction kettle to heat, and maintain the heating temperature at 90°C. After the wax is completely melted, add 100g mass fraction of 0.52% manganese sulfate and 12% stearic acid in batches , and reacted at 160°C for 5 hours through dry oxygen with a flow rate of 85mL / min to obtain oxidized wax;

[0032]Step 2. Add the oxidized wax prepared in step 1 into the reactor, and add stearic acid and triethanolamine according to the mass ratio of 5:2, sodium do...

Embodiment 2

[0037] see figure 1 Shown, a kind of paint protective wax, this protective wax is prepared by following raw material: 10 parts of paraffin wax, 10 parts of microcrystalline wax, 1 part of corrosion inhibitor, 20 parts of composite emulsifier, 3 parts of antioxidant, 10 parts of kaolin, 20 parts of environmental protection resin, 0.5 part of sodium dodecylbenzene sulfonate;

[0038] Wherein, the protective wax is prepared through the following steps:

[0039] Step 1. Put the weighed paraffin wax and microcrystalline wax into the reaction kettle to heat, and maintain the heating temperature at 75°C. After the wax is completely melted, add 100g mass fraction of 0.52% manganese sulfate and 12% stearic acid in batches , and reacted at 140°C for 3 hours through dry oxygen with a flow rate of 75mL / min to obtain oxidized wax;

[0040] Step 2. Add the oxidized wax prepared in step 1 into the reactor, and add stearic acid and triethanolamine according to the mass ratio of 5:2, sodium ...

Embodiment 3

[0045] see figure 1 Shown, a kind of paint protective wax, this protective wax is prepared by following raw material: 13 parts of paraffin wax, 13 parts of microcrystalline wax, 2 parts of corrosion inhibitor, 25 parts of composite emulsifier, 4 parts of antioxidant, 18 parts of kaolin, 25 parts of environmental protection resin, 1 part of sodium dodecylbenzene sulfonate;

[0046] Wherein, the protective wax is prepared through the following steps:

[0047] Step 1. Put the weighed paraffin wax and microcrystalline wax into the reaction kettle to heat, and maintain the heating temperature at 80°C. After the wax is completely melted, add 100g mass fraction of 0.52% manganese sulfate and 12% stearic acid in batches , and reacted at 150°C for 4 hours through dry oxygen with a flow rate of 80mL / min to obtain oxidized wax;

[0048] Step 2. Add the oxidized wax prepared in step 1 into the reactor, and add stearic acid and triethanolamine according to the mass ratio of 5:2, sodium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com