Preparation method of silica gel flatting agent used for paint

A technology of matting agent and silica gel, applied in the direction of coating, etc., can solve the problems of small pore volume, dispersed pore size distribution, and low transparency of silica gel matting agent, and achieve the effect of high transparency, concentrated pore size distribution, and reasonable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

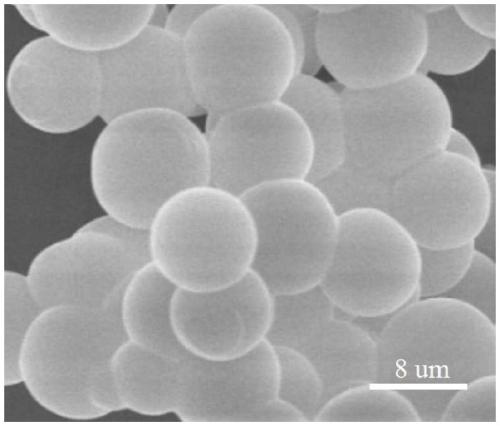

Image

Examples

Embodiment 1

[0022] A kind of preparation method of silica gel matting agent for paint, the preparation step of described silica gel matting agent for paint comprises:

[0023] Step 1, the generation of gel: the Na 2 SiO 3 The sodium silicate olefin solution with a content of 6% and the olefin sulfuric acid solution with a mass concentration of 20% are respectively hit at the reaction nozzle of the reactor under a pressure of 2KPa, so that it is synthesized into a silica sol at a high speed, wherein Na 2 SiO 3 with H 2 SO 4 The molar ratio is 1:1, and the temperature of the reaction system is 40°C;

[0024] Step 2, shrinkage molding of spherical silica sol: the silica sol generated through step 1 is dispersed into the oil bath of the forming column from the umbrella-shaped distribution plate. The temperature of the oil bath is 100 ° C, and it shrinks into a spherical shape by virtue of its own surface tension , Silica sol is extremely unstable under the condition of acidic pH=6.8 and ...

Embodiment 2

[0030] A kind of preparation method of silica gel matting agent for paint, the preparation step of described silica gel matting agent for paint comprises:

[0031] Step 1, the generation of gel: the Na 2 SiO 3 The sodium silicate olefin solution with a content of 6% and the olefin sulfuric acid solution with a mass concentration of 20% are respectively injected into the reaction nozzle of the reactor under a pressure of 1.8KPa to make it synthesize silica sol at a high speed, wherein Na 2 SiO 3 with H 2 SO 4 The molar ratio is 1:1, and the temperature of the reaction system is 35°C;

[0032] Step 2, shrinkage molding of spherical silica sol: the silica sol generated in step 1 is dispersed into the oil bath of the forming column from the umbrella-shaped distribution plate. The sol is extremely unstable under the condition of acidic pH=6.6 and heat, so it quickly coagulates into silica gel within 5s;

[0033] Step 3, acid soaking and washing: in a fume hood with a temperat...

Embodiment 3

[0038] A kind of preparation method of silica gel matting agent for paint, the preparation step of described silica gel matting agent for paint comprises:

[0039] Step 1, the generation of gel: the Na 2 SiO 3 The sodium silicate olefin solution with a content of 6% and the olefin sulfuric acid solution with a mass concentration of 20% are respectively hit at the reaction nozzle of the reactor under a pressure of 2.5KPa to make it synthesize silica sol at a high speed, wherein Na 2 SiO 3 with H 2 SO 4 The molar ratio is 1:1, and the system temperature is 50°C;

[0040]Step 2, shrinkage molding of spherical silica sol: the silica sol generated in step 1 is dispersed into the oil bath of the forming column from the umbrella-shaped distribution plate. The sol is extremely unstable under the condition of acidic pH=7.0 and heat, so it quickly coagulates into silica gel within 7s;

[0041] Step 3, acid soaking and washing: in a fume hood with a temperature of 35°C, soak the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com