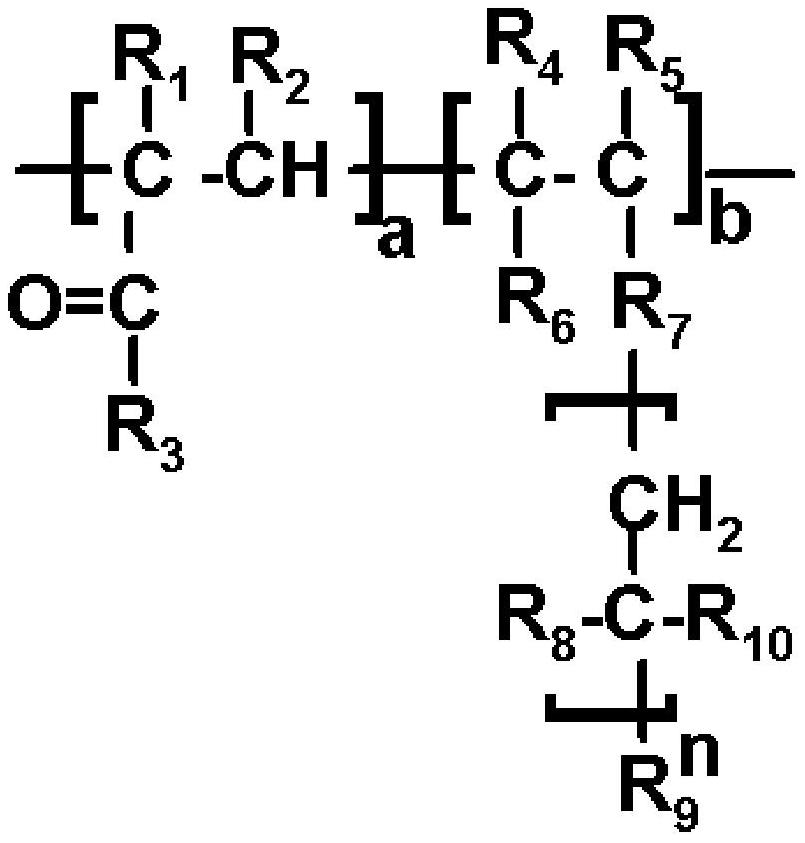

Synthesis method of side chain adsorption type concrete superplasticizer

A superplasticizer, adsorption-type technology, applied in the field of superplasticizer for cement concrete, can solve the problems of limited popularization and application, few anionic side chain macromonomers, difficult structure innovation and performance optimization, etc. Broad prospects, the effect of controlling the molecular weight distribution of products, improving product competitiveness and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

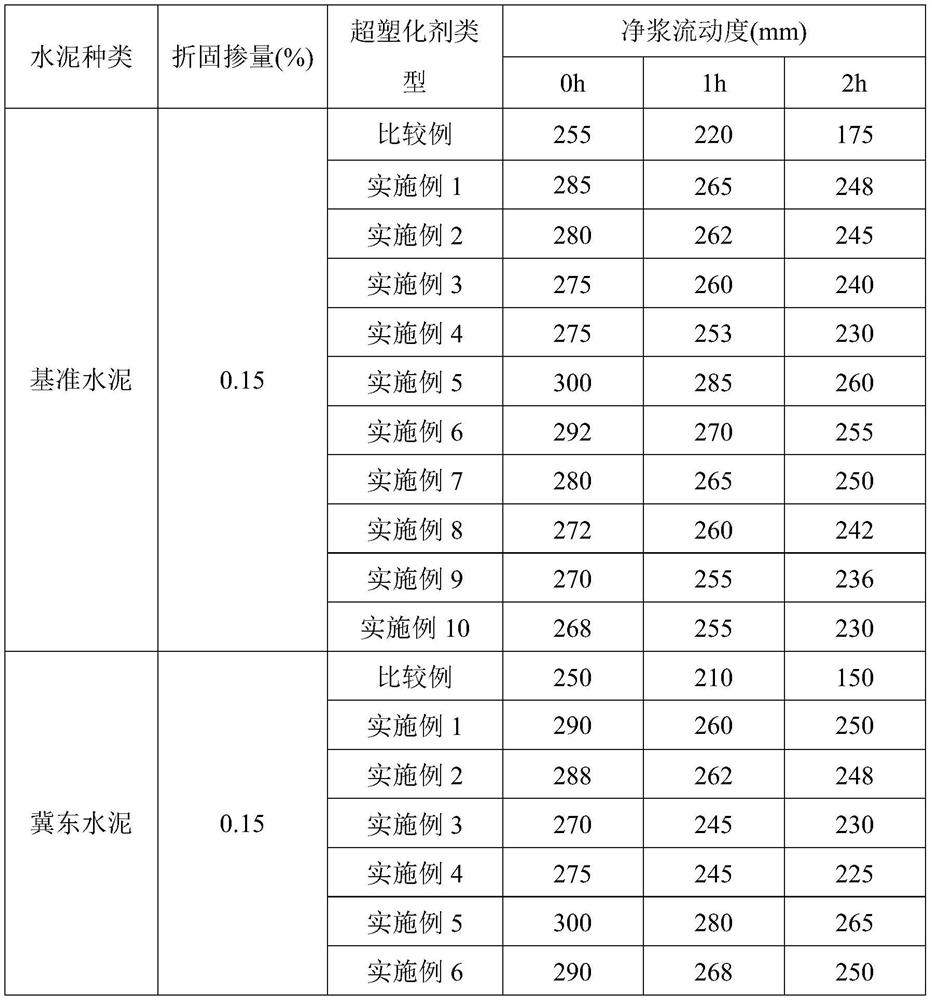

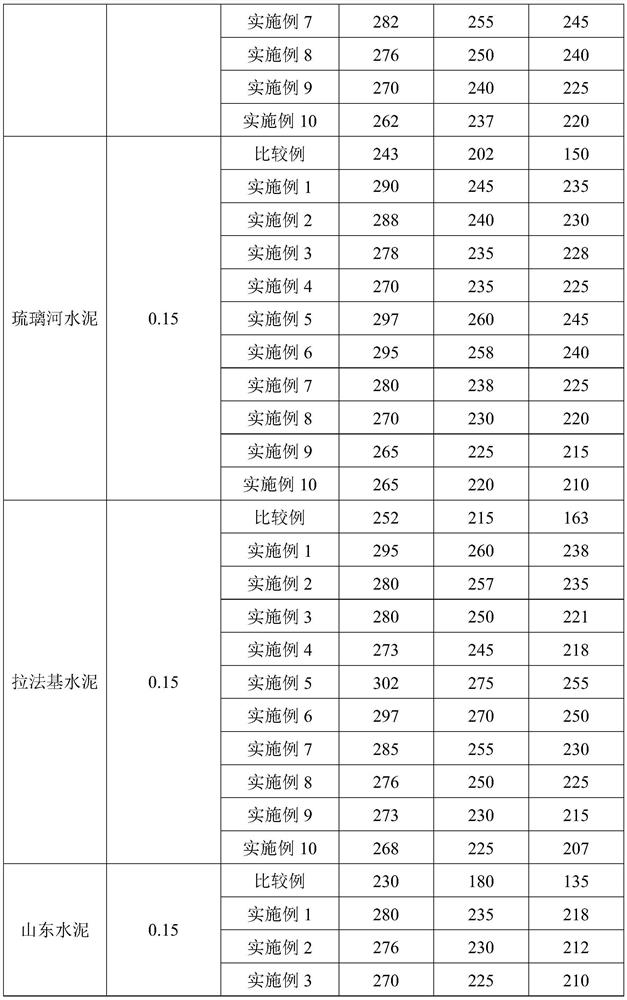

Examples

Embodiment 1

[0026] First, add 5.05g of acrylic acid, 30.27g of water, and 63.11g of ethylamine into the reactor and mix well, then add 1.79g of ethyl 2-bromoacrylate, 3.8g of ferrous chloride, 10.37g of 1,1,4,7,10,10 - Hexamethyltriethylenetetramine, the reactor was filled with nitrogen in an ice-water bath and deoxygenated repeatedly 5 times for 25 minutes, then stirred for 15 minutes until it was mixed evenly, sealed under nitrogen protection, and continued to heat up to 70°C for polymerization reaction. After 20 hours, the unsaturated macromonomer was obtained after desalting and vacuum distillation to remove the solvent; the obtained unsaturated macromonomer was mixed with 32.4 g of water, the temperature was raised to 60 ° C, and 2.56 g of HCl aqueous solution with a mass fraction of 20% was added, Hydrolyze for 50 minutes, after the hydrolysis is completed, distill under reduced pressure to remove water and by-products to obtain anionic macromonomer; finally dissolve the anionic macr...

Embodiment 2

[0028] After the 30% side chain adsorption concrete superplasticizer solution obtained in Example 1 was stored at 5° C. for 30 days, its implementation effect was measured.

Embodiment 3

[0030] First, 200.22g of ethyl acrylate and 400.44g of dimethylformamide were added to the reactor and mixed evenly, then 1.49g of 1-bromo-3-methyl-2-butene, 1.44g of cuprous bromide, 2.6g of N,N ,N,N,N-Pentamethyldivinyltriamine, the reactor was filled with nitrogen in an ice-water bath and deoxygenated 3 times for 15 minutes, then stirred for 30 minutes until it was evenly mixed, sealed under nitrogen protection and continued to heat up to 10°C Polymerization reaction was carried out at 90°C for 48 hours, desalination and vacuum distillation to remove the solvent to obtain the unsaturated macromonomer; the obtained unsaturated macromonomer was mixed with 161.37g of water, the temperature was raised to 90°C, and 8g was added with a mass fraction of 30 % sodium hydroxide aqueous solution, hydrolyzed for 10 minutes, after the hydrolysis was completed, decompression distillation sloughed water and by-products to obtain anionic macromonomer; finally anionic macromonomer was dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com