Spontaneous-combustion igniting agent

An igniter and self-igniting technology, which is applied in firelighters and the petroleum industry, can solve the problems of flash explosion, damage, and large volume of the ignition gun, and achieve the effects of controlling the delay time of self-ignition, preventing the flow of glycerin, and prolonging the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

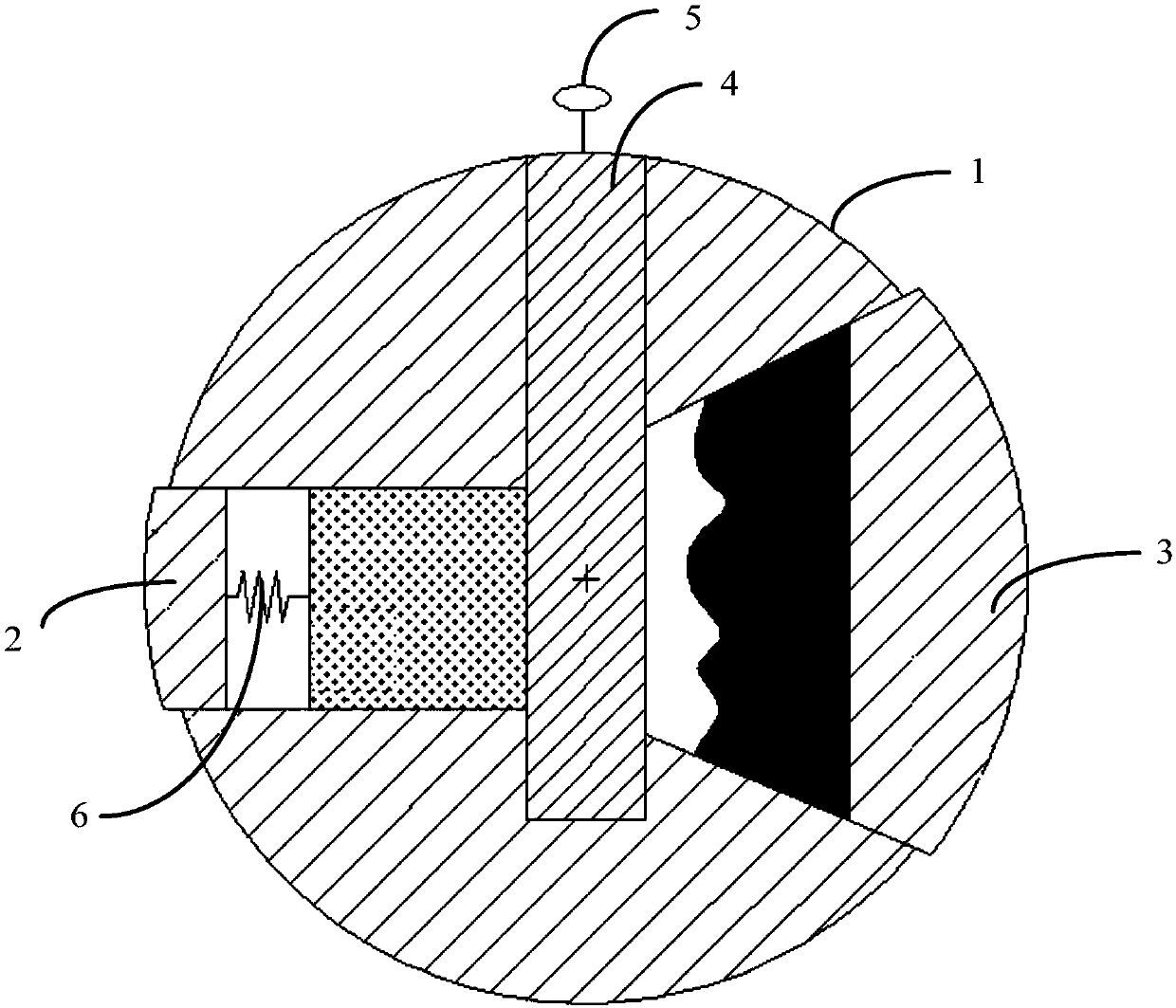

Image

Examples

Embodiment 1

[0039] This embodiment provides a self-igniting igniter.

[0040] 1) The self-igniting igniter provided in this embodiment includes the first system and the second system; wherein,

[0041] The raw material of the first system is composed of potassium ferrate, and the quality is 1g;

[0042]The raw material of the second system is composed of glycerin, corn cob powder and paraffin, and the mass ratio of the three is 1:5:4.2, wherein the quality of glycerin is 0.47g, the quality of corn cob powder is 2.35g, and the quality of paraffin wax is 1.98 g.

[0043] The preparation method of the second system is as follows:

[0044] Heat and melt paraffin at 70-90°C to form liquid paraffin;

[0045] Add glycerin and corn cob powder to liquid paraffin respectively, and stir for 3-5 minutes under heat preservation conditions, so that the surfaces of glycerin and corn cob powder are respectively wrapped with paraffin wax, and left to solidify, the surface of glycerin and corn cob powde...

Embodiment 2

[0055] This embodiment provides a self-igniting igniter.

[0056] 1) The self-igniting igniter provided in this embodiment includes the first system and the second system; wherein,

[0057] The raw material of the first system is composed of potassium ferrate, and the quality is 1g;

[0058] The raw material of the second system is composed of glycerin, corn cob powder and paraffin, and the mass ratio of the three is 1:5:4.2, wherein the quality of glycerin is 0.47g, the quality of corn cob powder is 2.35g, and the quality of paraffin wax is 1.98 g.

[0059] The preparation method of the second system is as follows:

[0060] Heat and melt paraffin at 70-90°C to form liquid paraffin;

[0061] Add glycerin and corn cob powder to liquid paraffin respectively, and stir for 3-5 minutes under heat preservation conditions, so that the surfaces of glycerin and corn cob powder are respectively wrapped with paraffin wax, and left to solidify, the surface of glycerin and corn cob powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com