High-strength environment-friendly PVC shrink film and preparation process thereof

A shrink film, high-strength technology, applied in the field of high-strength environmentally friendly PVC shrink film and its preparation, can solve the problems of poor quality of plastic products, affecting processing and performance, poor thermal stability, etc., to improve processing performance and reduce material thickness. , good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation process of high-strength environment-friendly PVC shrink film, comprising the steps of:

[0038] S1: After mixing polyvinyl chloride, ethylaniline, dioctyl ester and external lubricant, introduce it into a hot pot and heat it in a high-speed mixer at a speed of 1200-1800r / min;

[0039] S2: When the temperature reaches about 85°C, add plasticizer, heat stabilizer, internal lubricant and processing aid to the high-speed mixer, and fully mix for 1 minute;

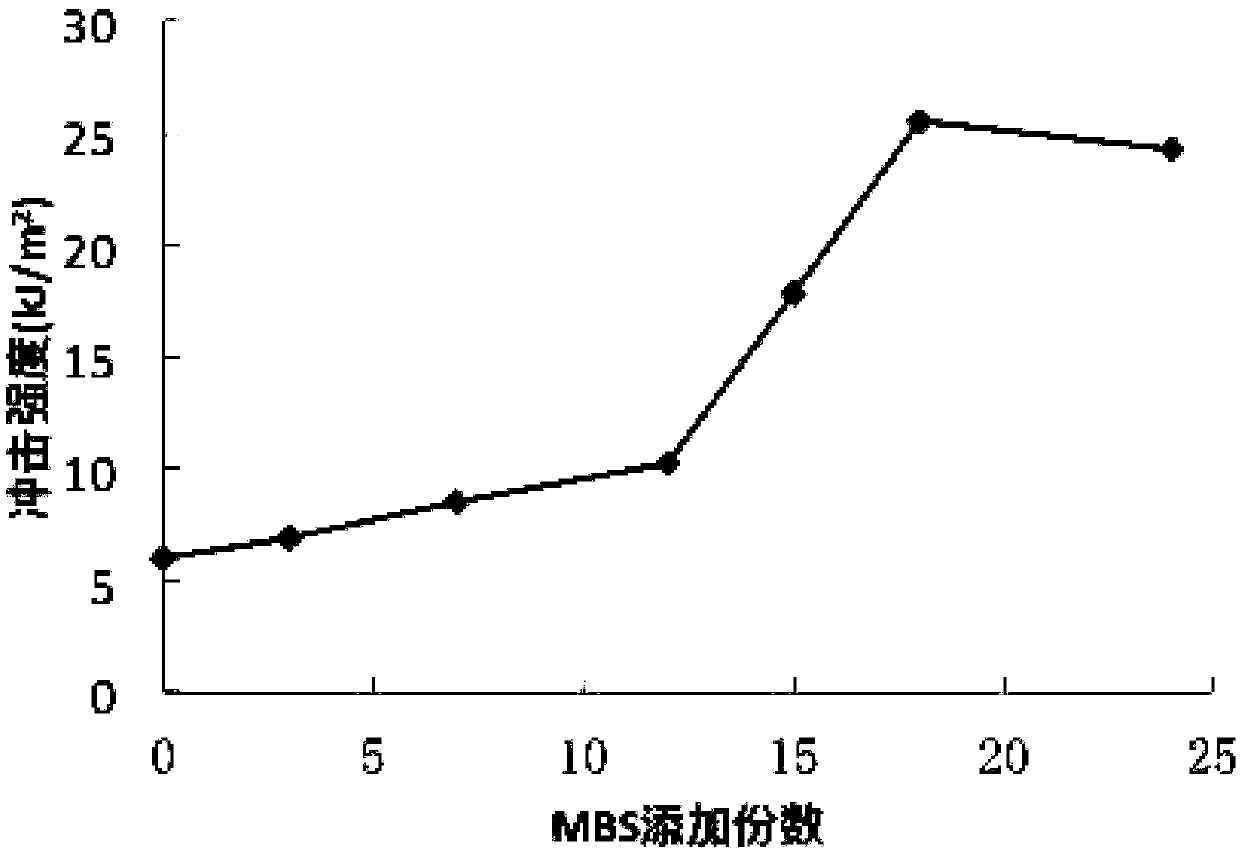

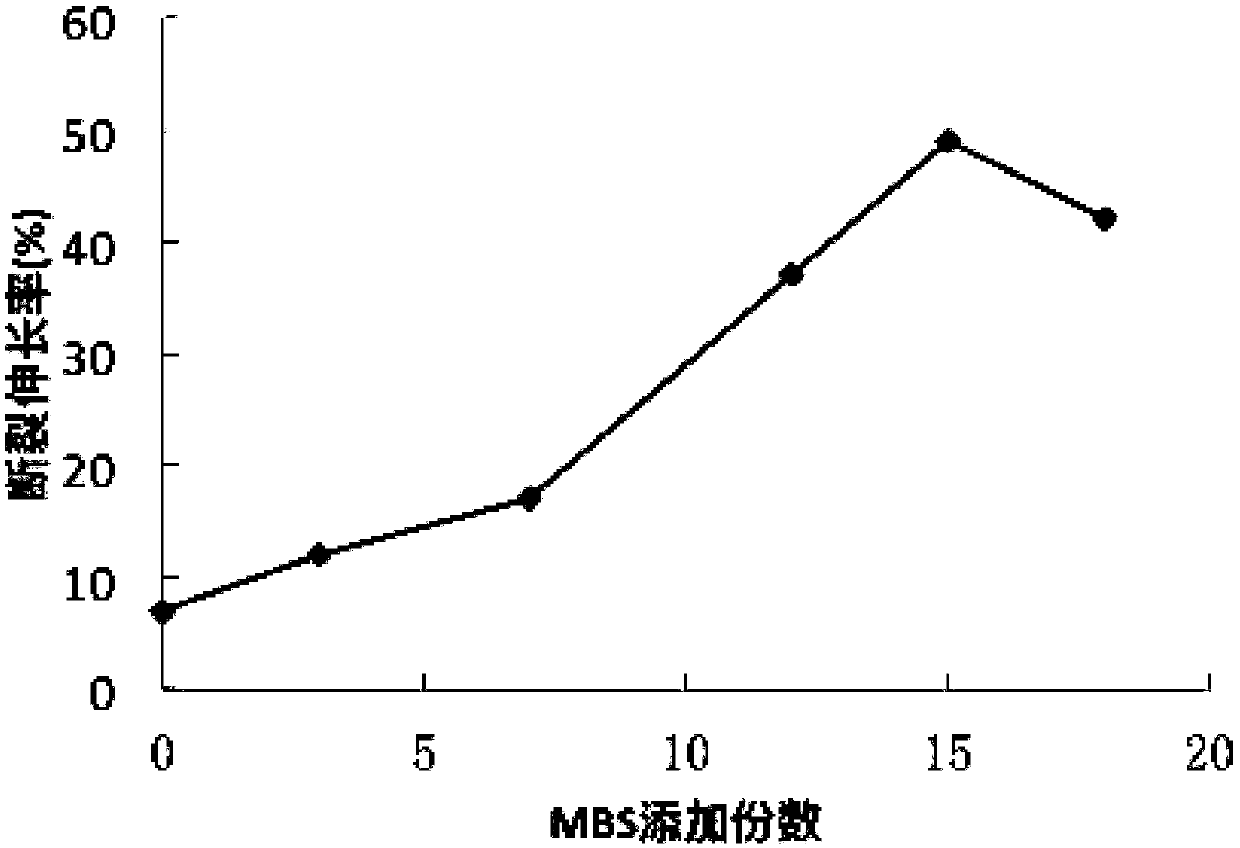

[0040] S3: Add the MBS resin to the high-speed mixer, and rapidly increase the mixing temperature to 130°C; mix the mixer at high speed for 6-8 minutes; obtain the mixture;

[0041] S4: The mixture blended in step S3 is in a molten state; extruded from an extruder with an aspect ratio of 30, blown by hot water for the first time, and then cooled and shaped by ice water to obtain a thick film;

[0042] S5: The thick film in step S4 is subjected to 80°C hot water for the second lateral inflation; cooled and...

Embodiment 1

[0048] A preparation process of high-strength environment-friendly PVC shrink film, comprising the steps of:

[0049] S1: Mix 97 parts of polyvinyl chloride, 8 parts of ethylaniline, 13 parts of dioctyl ester and 1 part of external lubricant, then introduce them into a hot pot and heat them in a high-speed mixer at a speed of 1400r / min;

[0050] S2: When the temperature reaches about 85°C, add 3 parts of plasticizer, 2 parts of heat stabilizer, 1 part of internal lubricant and 3 parts of processing aid into the high-speed mixer, and fully mix for 1 minute;

[0051] S3: Add 16 parts of MBS resin into the high-speed mixer, rapidly increase the mixing temperature to 130°C; mix the mixer at high speed for 8 minutes; obtain the mixture;

[0052] S4: The mixture blended in step S3 is in a molten state; extruded from an extruder with an aspect ratio of 30, blown by hot water for the first time, and then cooled and shaped by ice water to obtain a thick film;

[0053] S5: The thick fi...

Embodiment 2

[0056] A preparation process of high-strength environment-friendly PVC shrink film, comprising the steps of:

[0057] S1: Mix 99 parts of polyvinyl chloride, 9 parts of ethylaniline, 14 parts of dioctyl ester and 2 parts of external lubricant, then introduce them into a hot pot and heat them in a high-speed mixer at a speed of 1800r / min;

[0058] S2: When the temperature reaches about 85°C, add 3 parts of plasticizer, 3 parts of heat stabilizer, 2 parts of internal lubricant and 4 parts of working aid into the high-speed mixer, and fully mix for 1 minute;

[0059] S3: Add 18 parts of MBS resin into the high-speed mixer, rapidly increase the mixing temperature to 130°C; mix the mixer at high speed for 7 minutes; obtain the mixture;

[0060] S4: The mixture blended in step S3 is in a molten state; extruded from an extruder with an aspect ratio of 30, blown by hot water for the first time, and then cooled and shaped by ice water to obtain a thick film;

[0061] S5: The thick fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com