Low-dielectric-constant polyimide hybridized film and application thereof

A low dielectric constant, polyimide technology, applied in the field of polymer composite materials, can solve the problems of poor size uniformity of nano-void structure, poor dimensional stability of polyimide, and decreased mechanical properties of polyimide, etc. The effect of reducing dielectric constant loss, increasing thermal stability, and reducing dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

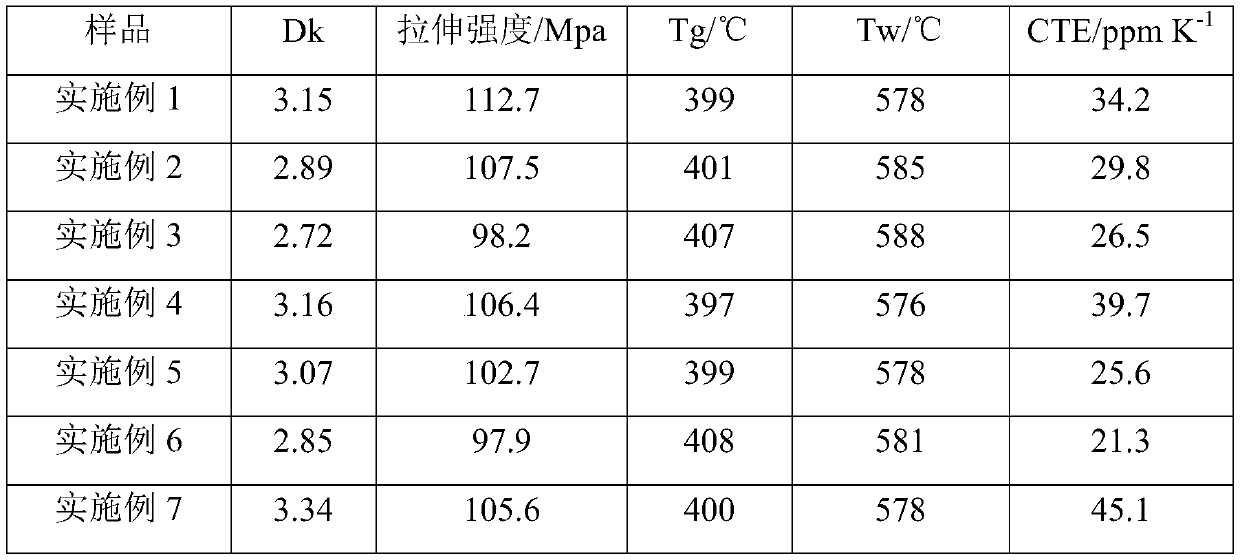

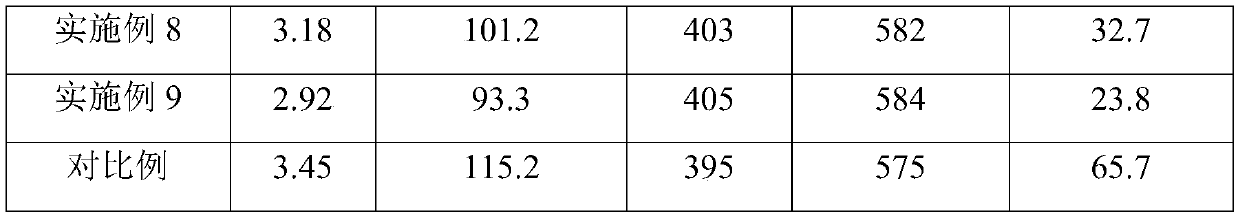

Examples

Embodiment 1

[0030] Put 100mL of 2mol / L sodium fluoride aqueous solution into a 200mL polytetrafluoroethylene liner, and then add 20g of porous MCM-41 (200nm) and 2g of polyethylene glycol (weight average molecular weight 6000) to the liner , Ultrasonic dispersion 6h. Then put the lining into another stainless steel reactor, seal the reactor, heat the reactor to 200°C, and keep it for 12 hours. After the reaction, the reactor is cooled to room temperature, and the supernatant is discarded. The precipitates were successively washed with distilled water, then vacuum-dried at 60°C, and ground into a fine powder to obtain surface fluorinated porous MCM-41 nanoparticles. Fully disperse 1 g of the above-mentioned fluorinated porous MCM-41 and 12 mmol 4,4-diaminodiphenyl ether in 40 mL of N,N-dimethylacetamide, sonicate for 4 hours, and then add 12 mmol 3,3 in three times within 30 min ',4,4'-biphenyltetracarboxylic dianhydride, and reacted at 25°C for 2 hours under the protection of nitrogen to...

Embodiment 2

[0032]Put 100mL of 2mol / L sodium fluoride aqueous solution into a 200mL polytetrafluoroethylene liner, and then add 20g of porous MCM-41 (250nm) and 2g of polyethylene glycol (weight average molecular weight 6000) to the liner , Ultrasonic dispersion 6h. Then put the lining into another stainless steel reactor, seal the reactor, heat the reactor to 200°C, and keep it for 12 hours. After the reaction, the reactor is cooled to room temperature, and the supernatant is discarded. The precipitate was washed successively with distilled water and ethanol, then dried in vacuum at 60°C, and ground into a fine powder to obtain surface fluorinated porous MCM-41 nanoparticles. Fully disperse 2g of the above-mentioned fluorinated porous MCM-41 and 12mmol 4,4-diaminodiphenyl ether in 40mL of N,N-dimethylacetamide, sonicate for 4h, and then add 12mmol 3,3 in three times within 30min ',4,4'-biphenyltetracarboxylic dianhydride, and reacted at 25°C for 2 hours under the protection of nitrogen ...

Embodiment 3

[0034] Put 100mL of 2mol / L sodium fluoride aqueous solution into a 200mL polytetrafluoroethylene liner, and then add 20g of porous MCM-41 (250nm) and 2g of polyethylene glycol (weight average molecular weight 6000) to the liner , Ultrasonic dispersion 6h. Then put the lining into another stainless steel reactor, seal the reactor, heat the reactor to 200°C, and keep it for 12 hours. After the reaction, the reactor is cooled to room temperature, and the supernatant is discarded. The precipitate was washed successively with distilled water and ethanol, then dried in vacuum at 60°C, and ground into a fine powder to obtain surface fluorinated porous MCM-41 nanoparticles. Fully disperse 4 g of the above-mentioned fluorinated porous MCM-41 and 12 mmol 4,4-diaminodiphenyl ether in 40 mL of N,N-dimethylacetamide, sonicate for 4 hours, and then add 12 mmol 3,3 in three times within 30 min ',4,4'-biphenyltetracarboxylic dianhydride, and reacted at 25°C for 2 hours under the protection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com