Preparation method of pH responsive agar and application thereof

A responsive, agar-based technology, which is used in the preparation of pH-responsive agar, and in the field of food industry, can solve the problems of agar molecular weight reduction, erosion, etc., and achieve the reduction of solidification temperature, enhancement of water retention, and improvement of gel transparency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of a single factor experiment with pH-responsive agar

[0039] 1.1 Selection of solid-liquid ratio

[0040] Step (1): Weigh the agar powder and add water in a certain proportion;

[0041] Step (2): Put the above-mentioned agar material solution in a reaction vessel, set its temperature to 35°C, and stir while heating;

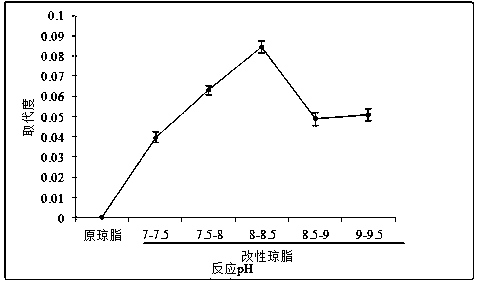

[0042] Step (3): When the temperature reaches the set temperature of 35°C, add 24 ml of octenyl succinic anhydride diluted to 5 times the volume with isopropanol drop by drop at a rate of 3 seconds per drop, and use NaOH solution to adjust during the reaction The reaction pH value is 8-8.5;

[0043] Step (4): Filter immediately after the reaction reaches 3 h. The washed agar powder was dried in a blast oven at 50°C for 24 h, and then crushed through a 100-mesh sieve to obtain pH-responsive agar.

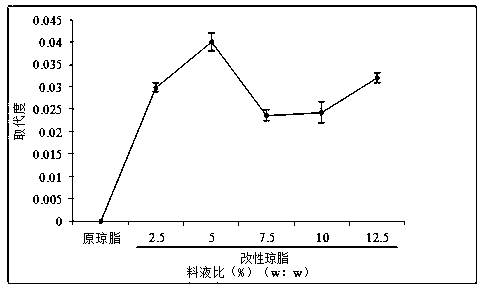

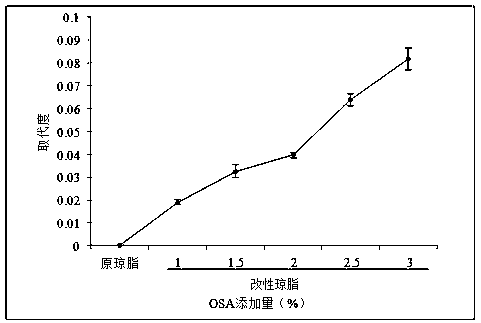

[0044] Such as figure 1As shown, when the solid-liquid ratio of the control reaction system is 5% (w:v), the degree of substitution...

Embodiment 2

[0070] Example 2: Application of modified agar (low solidification temperature, pH responsiveness) in embedding probiotics

[0071] Step (1): Weigh 2 g of sodium alginate, then add 100 ml of sterile distilled water and heat to dissolve;

[0072] Step (2): Weigh 2 g of agar, add 100 ml of sterile distilled water, and heat to dissolve completely;

[0073] Step (3): After mixing the two, keep them in a water bath at 45°C. When the temperature reaches the desired temperature, pour in the 10-fold diluted bacterial suspension, and use a homogenizer to homogenize at a low speed. After 3 min to obtain an emulsion, add it dropwise under mild stirring conditions to a mass fraction of 3% (w:v) CaCl 2 After the solution, after the formation of the microspheres, continue to stir for 20 min to solidify the microspheres, finally collect the microspheres, wash them twice with deionized water, and store them in normal saline.

[0074] Such as Figure 7 Shown, A: wet microspheres, B: dry mic...

Embodiment 3

[0075] Embodiment 3: Application of modified agar (high transparency) in jelly making

[0076] (1) Select the white fungus with bright white color, fat meat, no black spots, impurities and peculiar smell, put it in an appropriate amount of water, let it sit for more than 5 hours to make the dried white fungus fully absorb water and swell, remove the hard peduncle of the white fungus root, and then chop the white fungus into pieces and weighed. Put white fungus into water six times its weight, boil it at 90°C for 1 hour, grind it thoroughly with a beater, and then filter it with gauze to get white fungus pulp.

[0077] (2) Select fresh melons, cut them into pieces, store them in disposable plastic cups, and seal them with plastic wrap for later use.

[0078] (3) Weigh 0.5wt% gelatin and 0.5wt% high-transparency agar in the total system, and heat them in a microwave oven until they are completely dissolved to obtain a glue solution. Add the glue solution to the white fungus pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com