Carbon/carbon composite material surface mullite whisker-mullite/yttrium alumina silicate compound anti-oxidation coating and preparation method

A mullite whisker and carbon composite material technology, which is applied in the field of anti-oxidation coating preparation, can solve the problems of high porosity and low interface bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

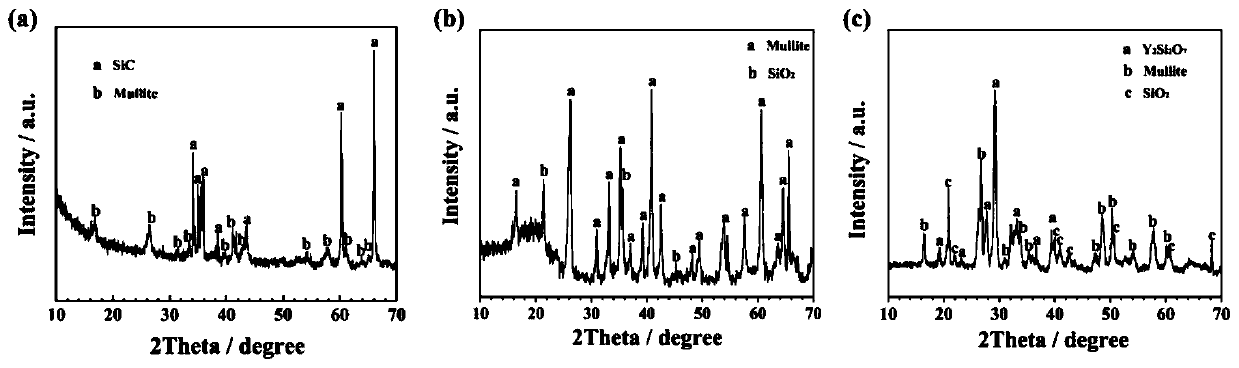

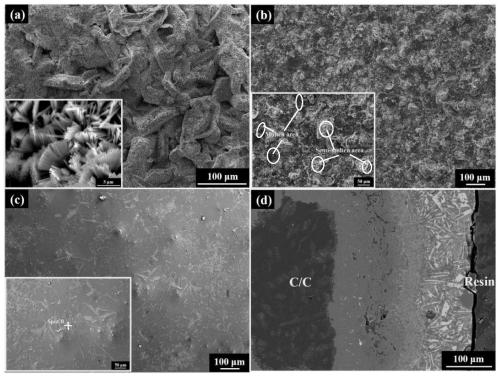

Embodiment 1

[0034] (1) Press Al 2 (SO 4 ) 3 18H 2 O: Na 2 SO 4 9H 2 O=1:1, take Al 2 (SO 4 ) 3 18H 2 O and Na 2 SO 4 9H 2 0, dry ball milling and mixing for 1h to prepare mixed salt A;

[0035] (2) Clean the SiC-C / C matrix sample ultrasonically, after drying, according to the mass ratio of SiC-C / C matrix sample: mixed salt A=1:10, the SiC-C / C composite material sample The samples were embedded in mixed salt A, and heat-treated in a muffle furnace at a temperature of 950°C for 20 minutes;

[0036] (3) Wash the sample treated in step (2) with boiling water, then dry the sample in an electric blast drying oven at 80°C for 4 hours to obtain a sample with a mullite whisker layer;

[0037] (4) With a concentration of 1wt% polyvinyl alcohol solution as a binder, mix in a ball mill according to the mass ratio of commercially available mullite powder: distilled water: absolute ethanol: polyvinyl alcohol = 4:4:1:1 Uniform, and then use spray granulation method to granulate. During sp...

Embodiment 2

[0045] (1) Press Al 2 (SO 4 ) 3 18H 2 O: Na 2 SO 4 9H 2 O=9:10, take Al 2 (SO 4 ) 3 18H 2 O and Na 2 SO 4 9H 2 O, dry ball milling and mixing for 2h to prepare mixed salt A;

[0046] (2) Clean the SiC-C / C matrix sample ultrasonically, after drying, according to the mass ratio of SiC-C / C matrix sample: mixed salt A=1:15, the SiC-C / C composite material sample The sample was embedded in mixed salt A, and heat-treated in a muffle furnace at a temperature of 900°C for 30 minutes;

[0047] (3) Wash the sample treated in step (2) with boiling water, then dry the sample in an electric blast drying oven at 100°C for 3 hours to obtain a sample with a mullite whisker layer;

[0048] (4) With a concentration of 3wt% polyvinyl alcohol solution as a binder, mix in a ball mill according to the mass ratio of commercially available mullite powder: distilled water: absolute ethanol: polyvinyl alcohol = 4:4:1:1 Uniform, and then use spray granulation method to granulate. During sp...

Embodiment 3

[0056] (1) Press Al 2 (SO 4 ) 3 18H 2 O: Na 2 SO 4 9H 2 O=4:5, take Al 2 (SO 4 ) 3 18H 2 O and Na 2 SO 4 9H 2 O, dry ball milling and mixing for 3h to prepare mixed salt A;

[0057] (2) Clean the SiC-C / C matrix sample ultrasonically, and after drying, according to the mass ratio of SiC-C / C matrix sample: mixed salt A=1:20, the SiC-C / C composite material sample The sample was embedded in mixed salt A, and heat-treated in a muffle furnace at a temperature of 1000°C for 15 minutes;

[0058] (3) Wash the sample treated in step (2) with boiling water, then dry the sample in an electric blast drying oven at 120°C for 2 hours to obtain a sample with a mullite whisker layer;

[0059](4) With a concentration of 2wt% polyvinyl alcohol solution as a binder, mix in a ball mill according to the mass ratio of commercially available mullite powder: distilled water: absolute ethanol: polyvinyl alcohol = 4:4:1:1 Uniform, and then granulated by spray granulation method. During sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com