Method for preparing pet feed by using kitchen waste

A pet feed and kitchen waste technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problem of high operating cost, low added value of feed products, and insufficient use of the nutritional value of kitchen waste. and other problems, to achieve the effect of good sterilization effect, turning waste into treasure with added value, and unaffected nutrients and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

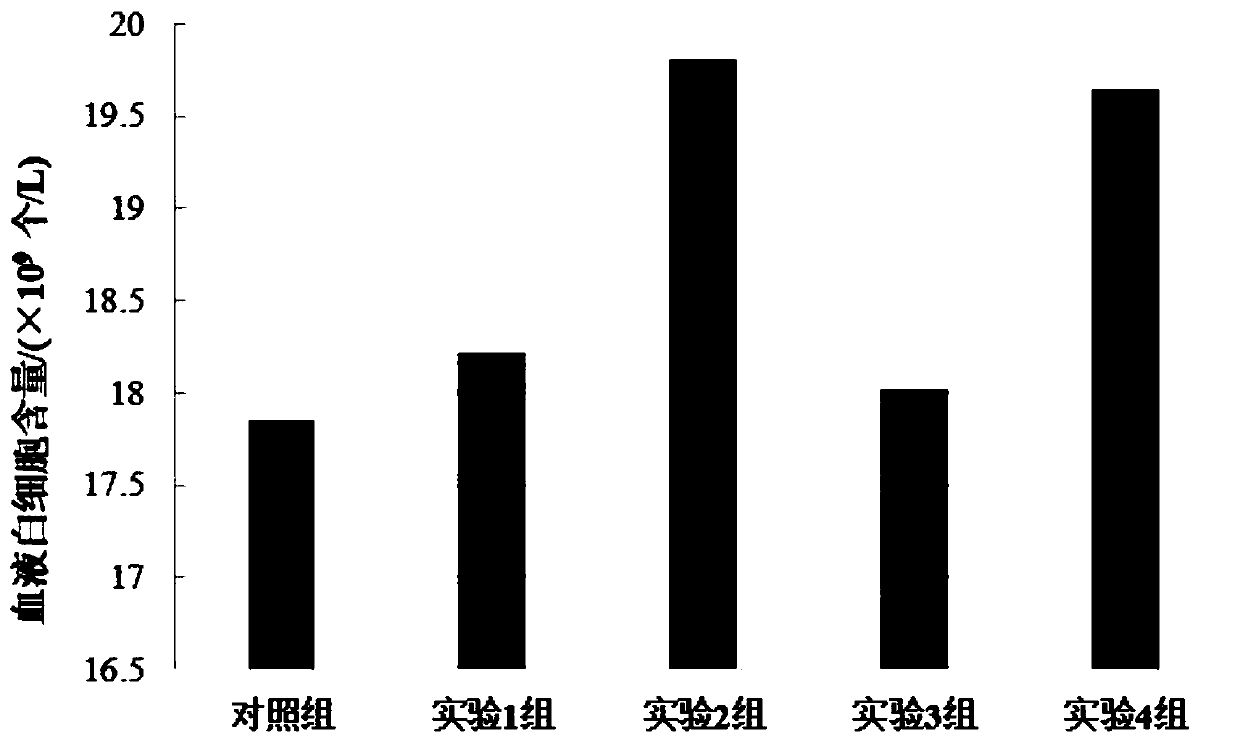

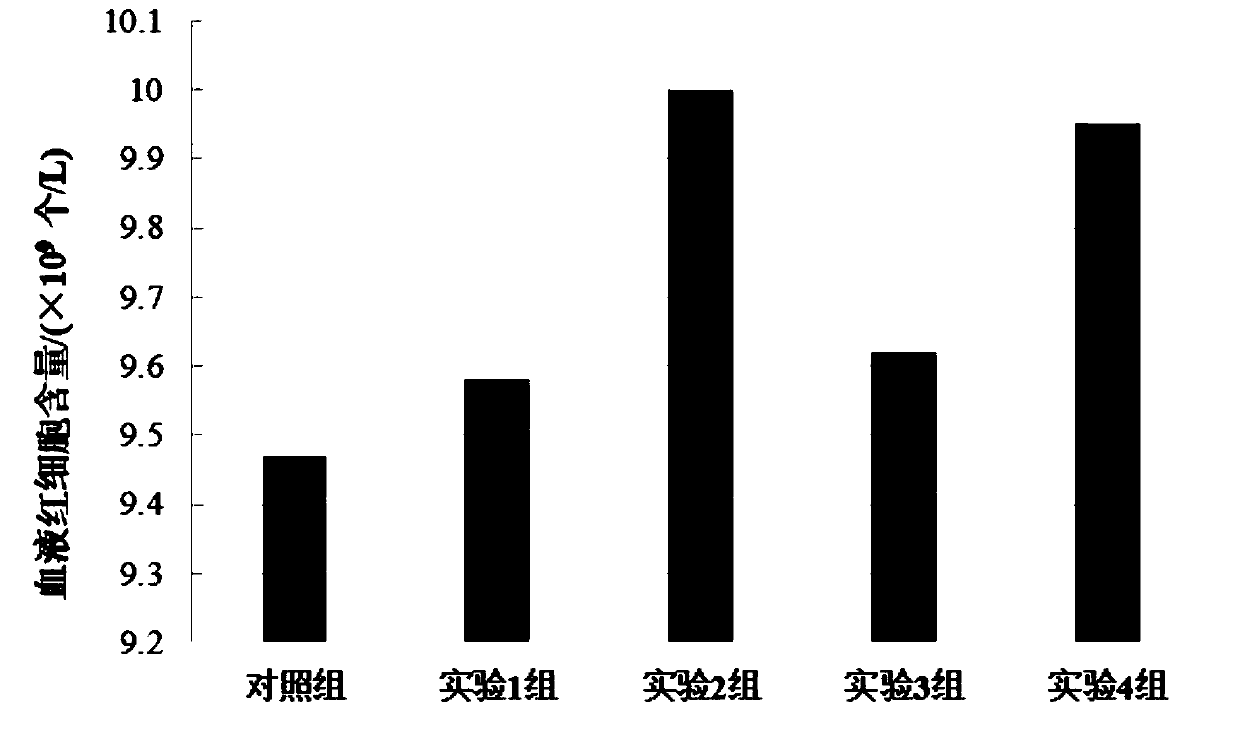

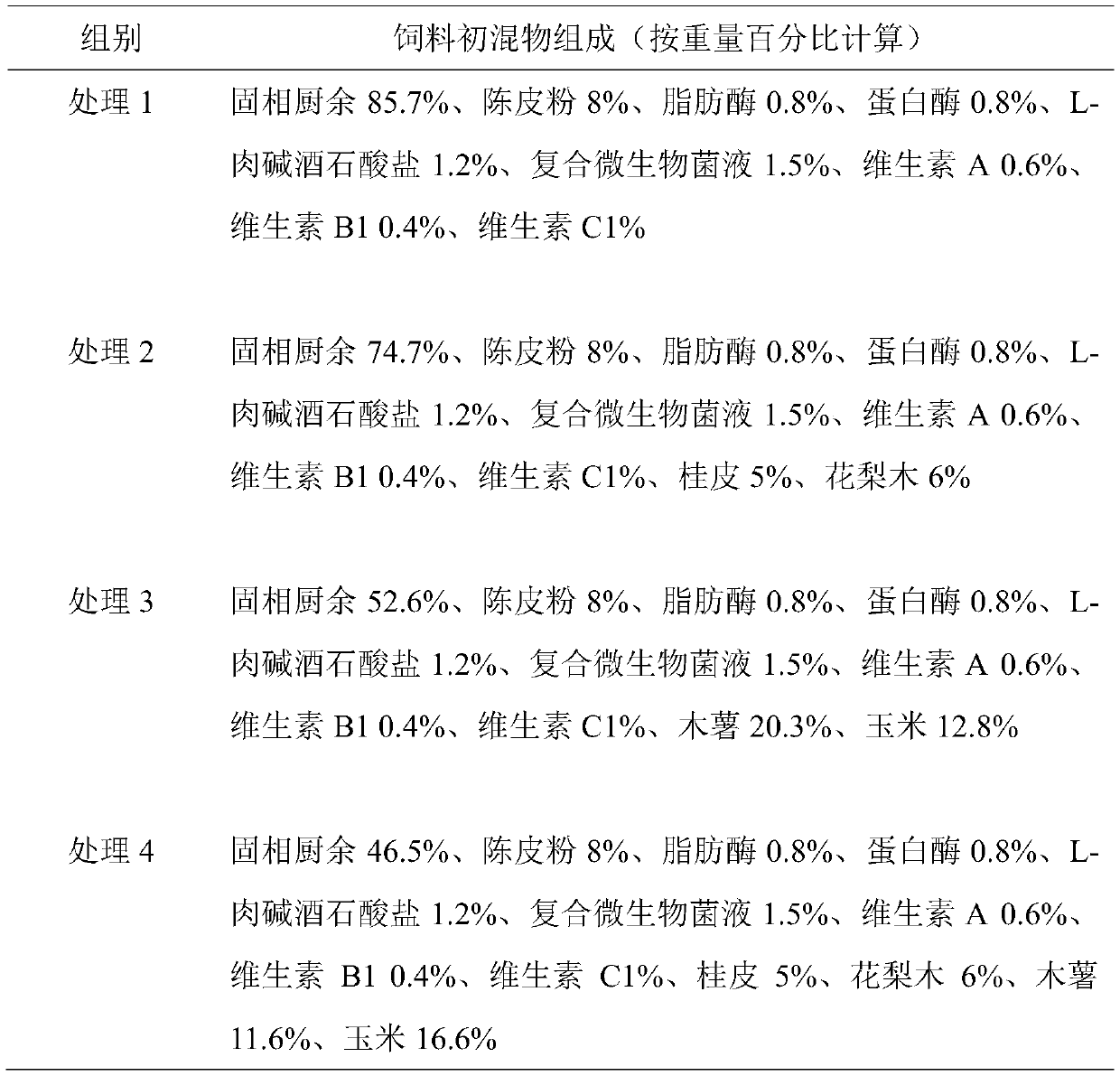

[0026] 1. Processing group settings

[0027] In this embodiment, 4 treatment groups are set up, and kitchen waste is used to prepare pet feed. The setting of the treatment groups takes the composition of the feed primary mixture as a variable, and the specific composition of the feed primary mixture corresponding to each treatment group is shown in Table 1, wherein , the protein content and fat content of the product made by treatment 3 were 18.1% and 5.2% respectively, and the protein content and fat content of the product made by treatment 4 were 18.0% and 5.1% respectively. In this embodiment, common commercially available full-price pet feed is set as a control group. The compound microorganism bacterium liquid that the treatment group of present embodiment adopts contains 2 * 10 9 -5×10 9 CFU / g Lactobacillus acidophilus, 0.8×10 8 -1.5×10 8 CFU / g of Saccharomyces boulardii and 2×10 9 -5×10 9 CFU / g of Bacillus subtilis. Except for the variables listed in Table 1, all...

Embodiment 2

[0052] 1. Processing group settings

[0053] This example is an optimization experiment of the beating process of feed primary mixture. This example sets up treatment I and treatment II, wherein: treatment I takes the material-liquid ratio during beating as a variable, and respectively makes solid-phase kitchen waste + additives + auxiliary materials: water =1:1, 2:1, 3:1, 4:1, 5:1, add clean water at 0°C to the solid material; treatment II takes the temperature of the added water as a variable, and follow the ratio of 3:1 when beating Ratio of solid to liquid, add clean water at 0°C, 5°C, 10°C, 15°C, and 20°C to the solid material respectively. In addition to the aforementioned variables, all corresponding technical points were strictly consistent across treatment groups.

[0054] The treatment group that the present embodiment is set makes feed primary mixture according to the following method:

[0055] (1) Separation of food waste residue, sorting and filtering the solid ...

Embodiment 3

[0067] 1. Processing group settings

[0068] This embodiment is a beating process optimization experiment for gamma ray sterilization. This embodiment sets up treatment A and treatment B, wherein: treatment A takes the irradiation dose of gamma rays as a variable, and makes the gamma rays 2, 4, 6, 8, 10Gy, irradiated for 4min; treatment B, with the irradiation time of γ-rays as a variable, irradiated with γ-rays with a radiation dose of 4Gy for 2, 4, 6, 8, and 10 minutes respectively. In addition to the aforementioned variables, all corresponding technical points were strictly consistent across treatment groups. The treatment group of the present embodiment prepares pet feed according to the following steps:

[0069] (1) Separation of food waste residue, sorting and filtering the solid food waste obtained after filtering off the oil-water mixture, discarding inedible waste such as table paper, to obtain usable solid-phase kitchen waste, and separating the solid-phase kitchen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com