Efficient perovskite quantum dot anion exchange method

A perovskite and quantum dot technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of low stability and poor efficiency of perovskite nanocrystals, and achieve good environmental stability , good monodispersity, good monochromatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

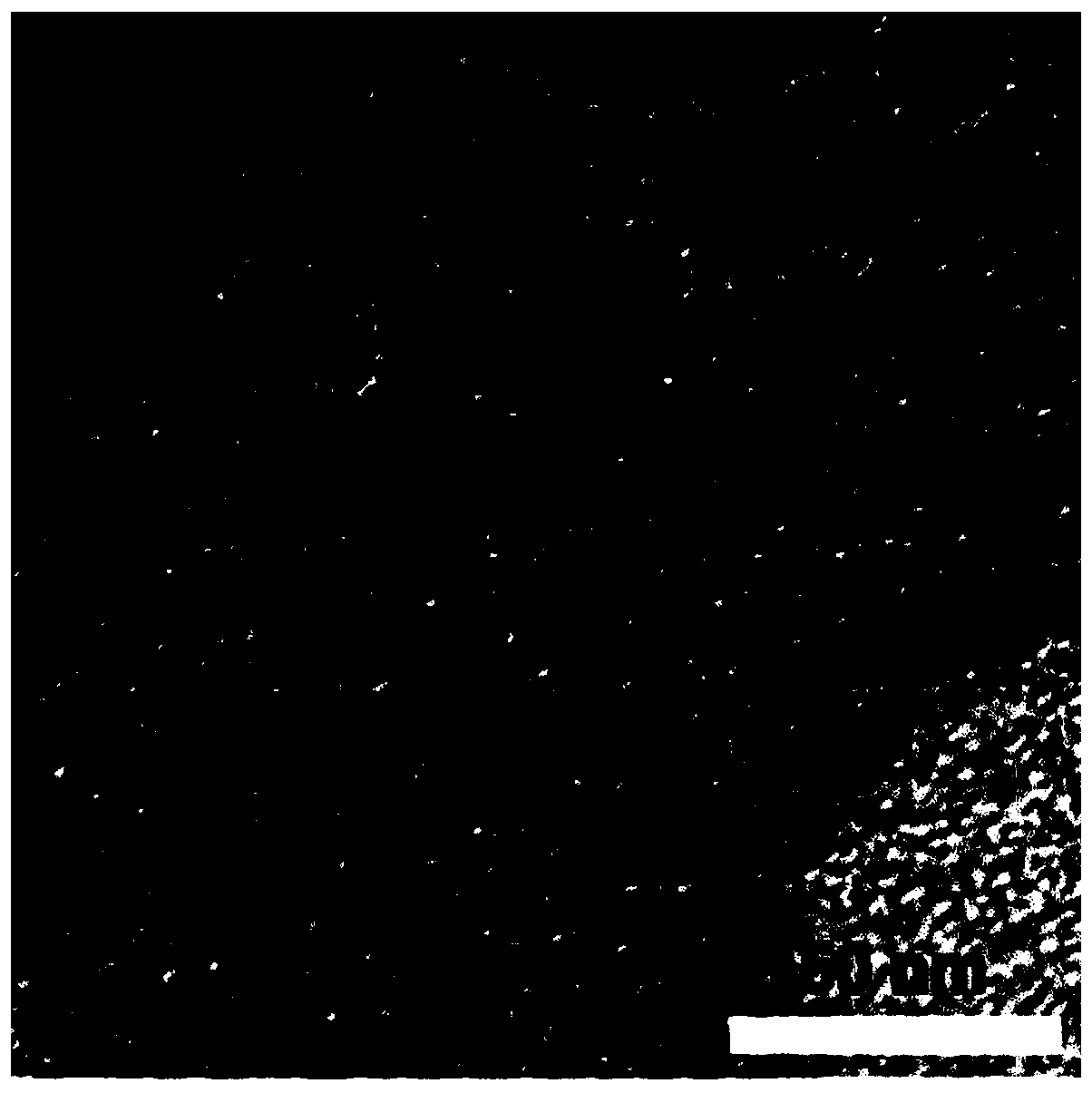

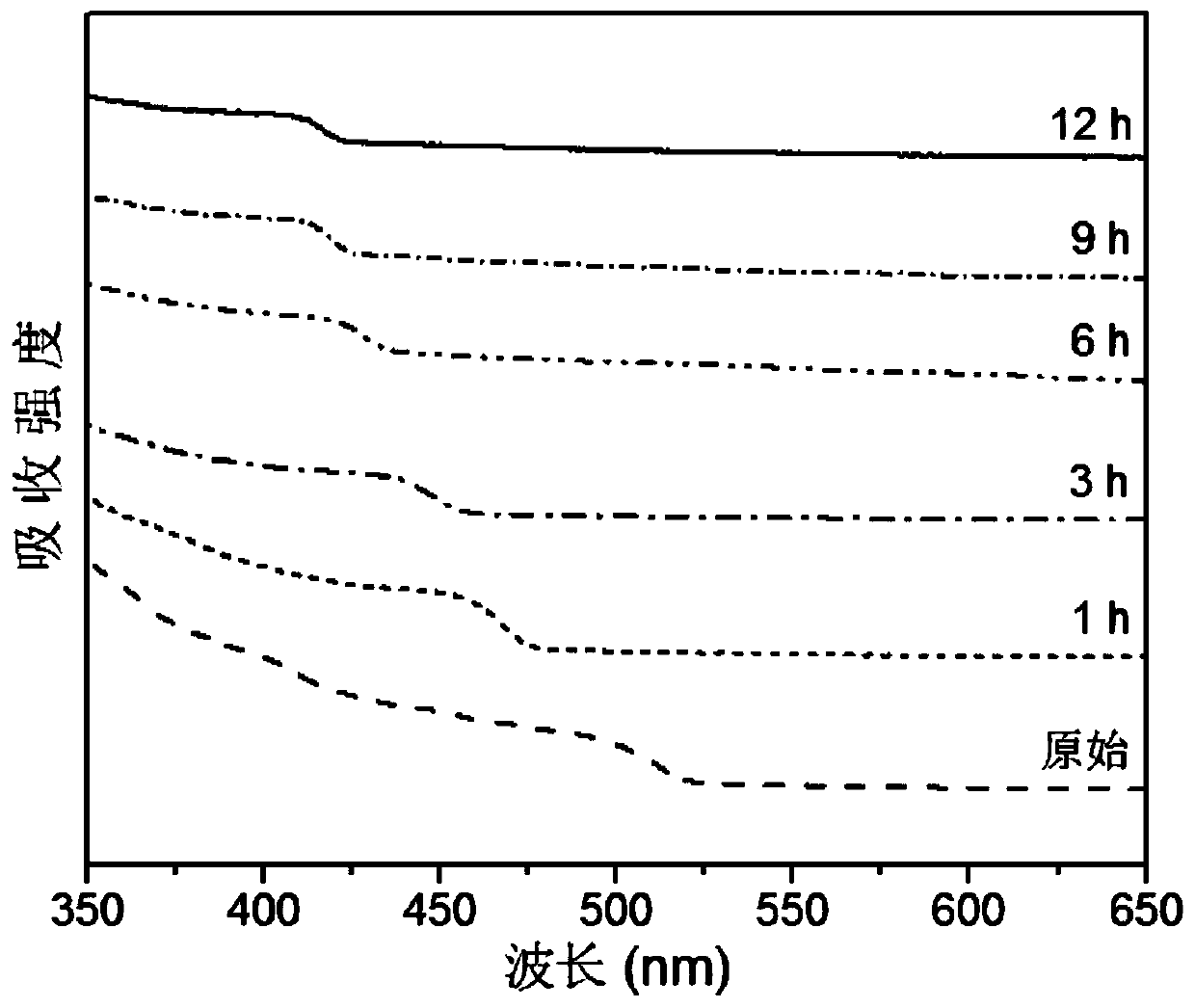

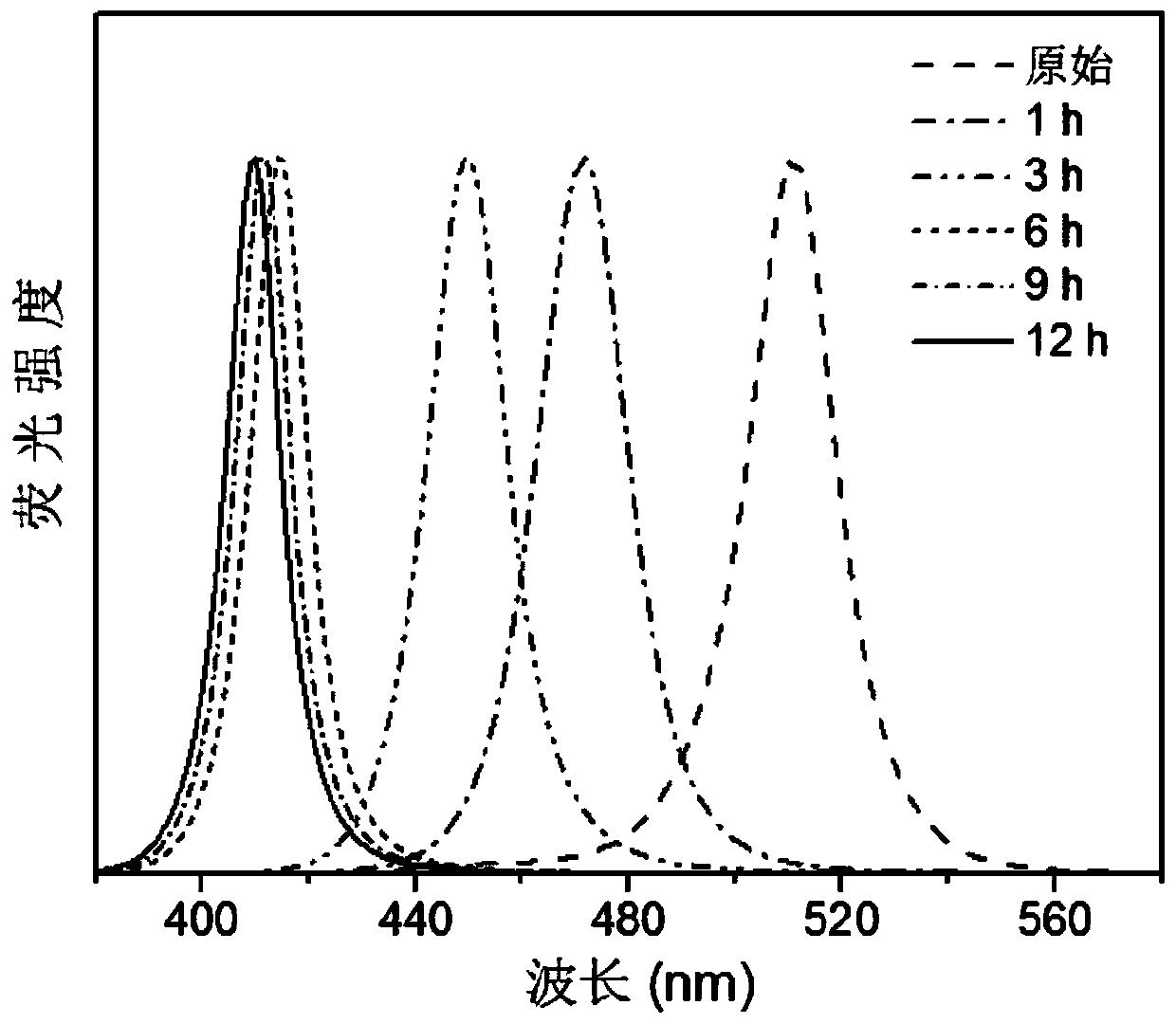

Embodiment 1

[0021] The CsPbCl of this embodiment 3 The preparation method of perovskite quantum dot anion exchange material comprises the following steps:

[0022] (1) Weigh 0.407g of cesium carbonate and add it to 20mL of octadecene (ODE) and 1.25ml of oleic acid (OA) in a 100ml three-necked flask; turn on the heating platform, vacuumize at 120°C for 1h, and then pass N 2 , heated to 150°C under its atmosphere until all solid powders were completely reacted and dissolved, and the liquid was transparent. Octadecene (ODE) 5mL, oleic acid (OA) 2mL, oleylamine (OAm) 2mL, lead bromide (PbBr 2 )0.0690g (0.188mmol) was mixed in a 25ml three-necked flask, heated to 120°C and vacuumed for 1h, N 2 Stir at 120°C under the atmosphere (stirring speed is 300r / min) until the solid is completely dissolved to obtain a bromide solution. After the temperature is stable, heat up to 160°C again and inject 0.4ml of Cs-oil precursor. After reacting for 5s, proceed quickly Cool in an ice water bath. After t...

Embodiment 2

[0026] This embodiment CsPbCl 3 The preparation method of the perovskite quantum dot anion exchange material comprises the steps:

[0027] (1) Weigh 0.407g of cesium carbonate and add it to 20mL of octadecene (ODE), 1.25ml of oleic acid (OA) OA mixed solution in a 100ml three-necked flask; turn on the heating platform, vacuumize at 120°C for 1h, and then pass N 2 , heated to 150°C under its atmosphere until all solid powders were completely reacted and dissolved, and the liquid was transparent. Octadecene (ODE) 5mL, oleic acid (OA) 2mL, oleylamine (OAm) 2mL, lead bromide (PbBr 2 )0.0690g (0.188mmol) was mixed in a 25ml three-necked flask, heated to 120°C and vacuumed for 30min, N 2 Stir at 120°C under the atmosphere (stirring speed is 300r / min) until the solid is completely dissolved to obtain a bromide solution. After the temperature is stable, heat up to 160°C again and inject 0.4ml of Cs-oil precursor. After reacting for 5s, proceed quickly Cool in an ice water bath. Af...

Embodiment 3

[0031] This embodiment CsPbCl 3 The preparation method of the perovskite quantum dot anion exchange material comprises the steps:

[0032] (1) Weigh 0.407g of cesium carbonate and add it to 20mL of octadecene (ODE) and 1.25ml of oleic acid (OA) in a 100ml three-necked flask; turn on the heating platform, vacuumize at 120°C for 1h, and then pass N 2 , heated to 150°C under its atmosphere until all solid powders were completely reacted and dissolved, and the liquid was transparent. Octadecene (ODE) 5mL, oleic acid (OA) 2mL, oleylamine (OAm) 2mL, lead bromide (PbBr 2 )0.0690g (0.188mmol) was mixed in a 25ml three-necked flask, heated to 120°C and vacuumed for 30min, N 2 Stir at 120°C under the atmosphere (stirring speed is 300r / min) until the solid is completely dissolved to obtain a bromide solution. After the temperature is stable, heat up to 160°C again and inject 0.4ml of Cs-oil precursor. After reacting for 5s, proceed quickly Cool in an ice water bath. After the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com