Trench silicon carbide MOSFET device and preparation method thereof

A silicon carbide and groove-type technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as bonding wire stray inductance, reduce conduction voltage, and miniaturization constraints, and achieve improved Effects of current density, reduced on-resistance, reduced parasitic inductance, and system loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific implementation modes, and various modifications or changes can be made to the details in this specification based on different viewpoints and applications without departing from the spirit of the present invention.

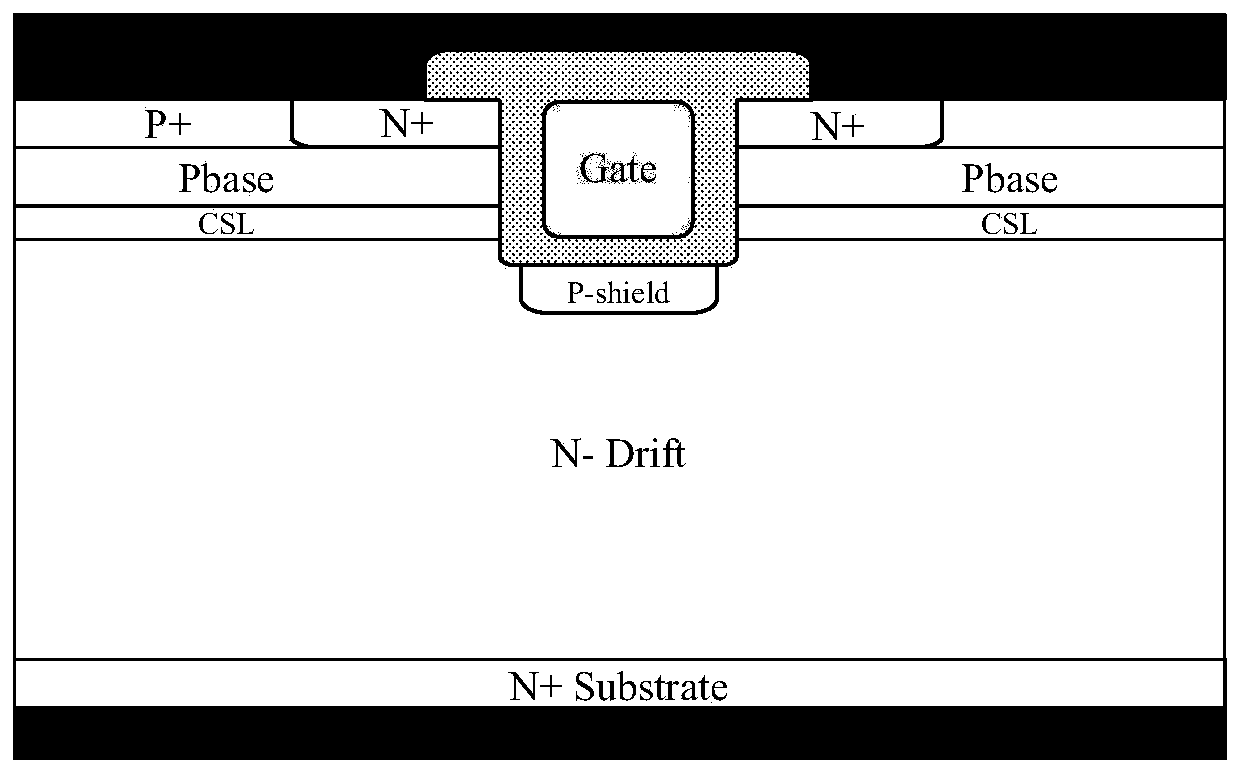

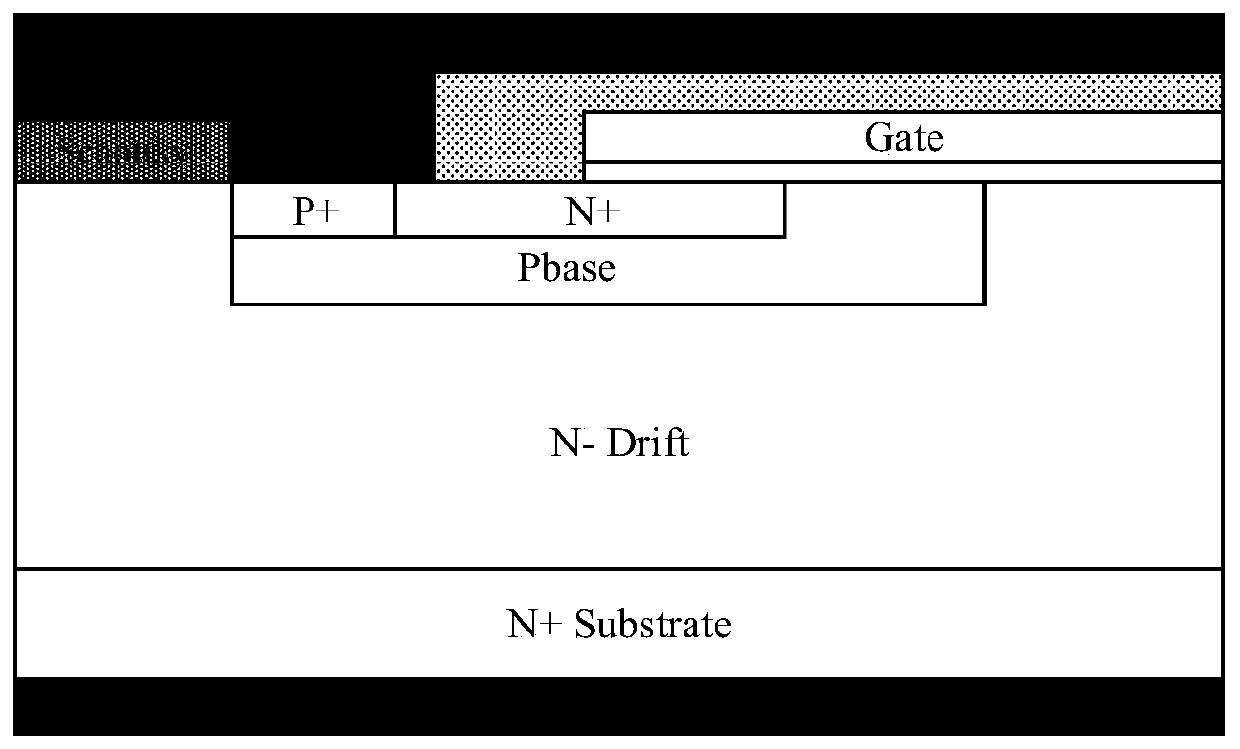

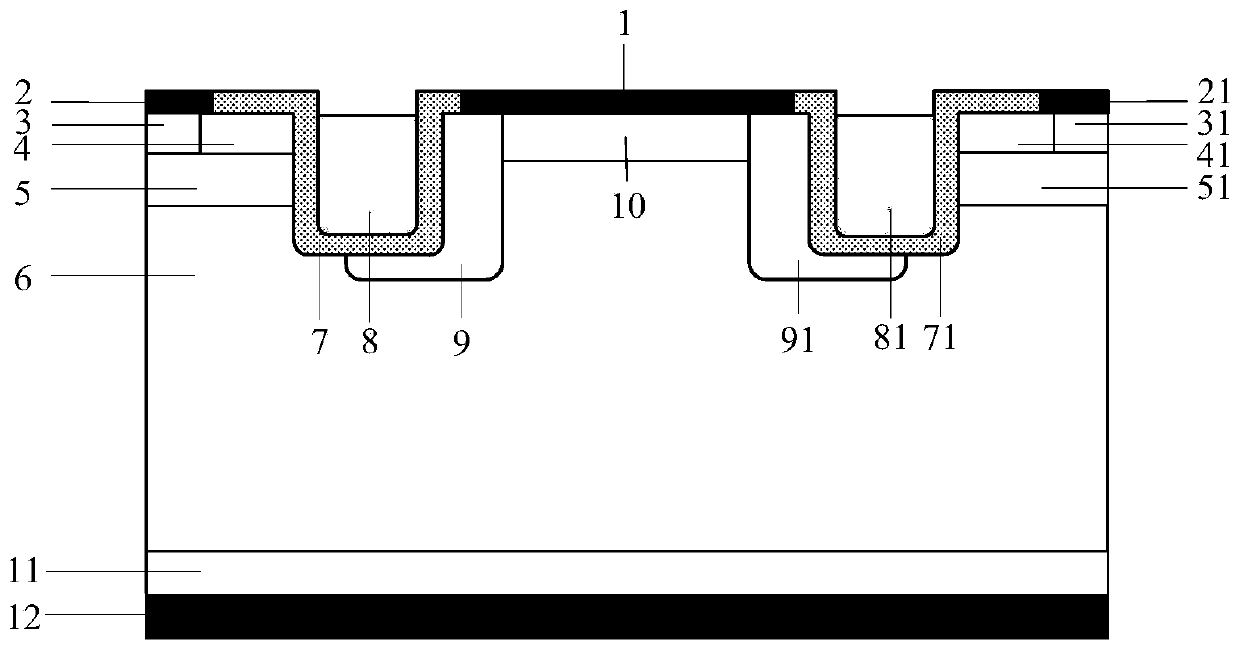

[0029] Such as image 3As shown, a trench silicon carbide MOSFET device includes: a drain metal 12, an N+ substrate 11 above the drain metal 12, an N-drift region 6 above the N+ substrate 11; the N-drift region 6 An N+ ohmic contact region 10 is provided in the middle of the interior of the upper part; the first P+ region 9 is provided on the left side of the N+ ohmic contact region 10, and the second P+ region 91 is provided on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com