Handling method for metallurgy solid waste

A solid waste and treatment method technology, applied in the field of iron and steel metallurgy, can solve the problems of poor treatment effect of metallurgical solid waste dust, unsatisfactory treatment effect, low resource utilization rate, etc., to prevent sticking, reduce fuel consumption, and promote reduction separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

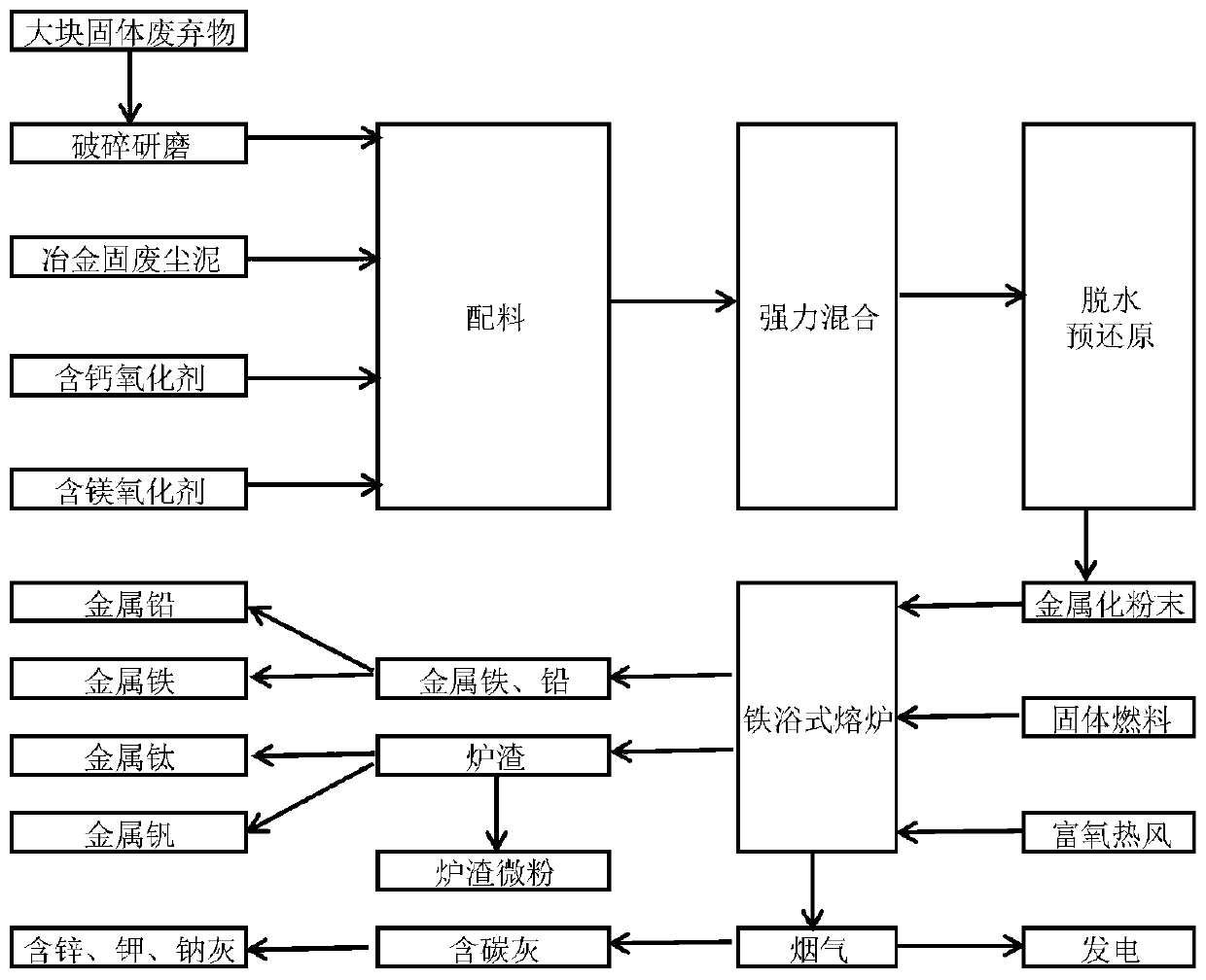

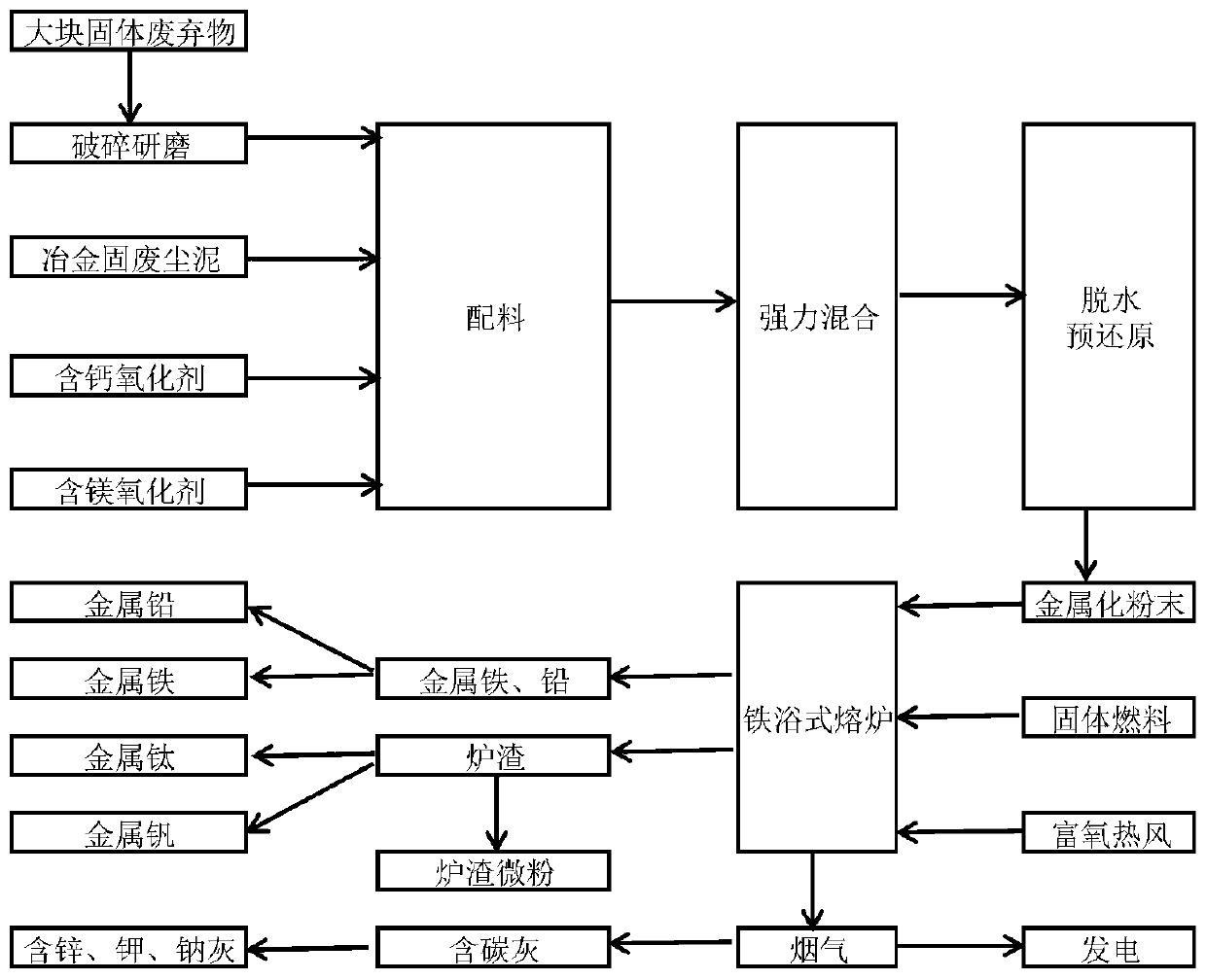

Method used

Image

Examples

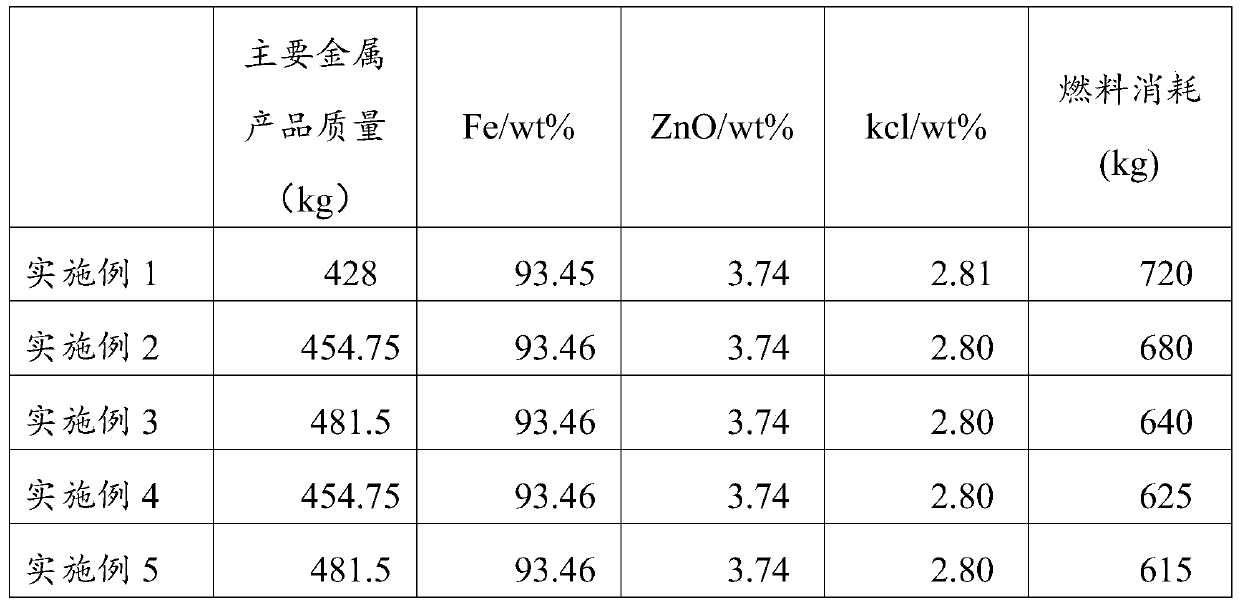

Embodiment 1

[0044] Embodiment 1 of the present invention discloses a method for processing metallurgical solid waste, which specifically includes the following steps:

[0045] (1) first crush and grind metallurgical solid waste, and sieve through a 6mm sieve;

[0046](2) Weigh metallurgical solid waste, calcium-containing oxides and magnesium-containing oxides according to the mass ratio of 80:10:10; among them, metallurgical solid waste includes environmental dust removal ash, sintering dust, pellet dust, blast furnace dust , Converter dust, electric furnace dust, steel slag, steel rolling dust, iron scale, iron red, coking dust and other solid waste, calcium oxides include quicklime, limestone, dolomite One or more mixtures, magnesium-containing oxides include single or multiple mixtures of magnesite, light burnt dolomite, serpentine, and dolomite.

[0047] (3) The mixture is dried and dehydrated, and the water content of the dried mixture is 2 wt%.

[0048] (4) Carry out pre-reductio...

Embodiment 2

[0055] Embodiment 2 of the present invention discloses a method for processing metallurgical solid waste, which specifically includes the following steps:

[0056] (1) first crush and grind metallurgical solid waste, and sieve through a 6mm sieve;

[0057] (2) Weigh metallurgical solid waste, calcium-containing oxides and magnesium-containing oxides respectively according to the mass ratio of 85:7:8; among them, metallurgical solid waste includes environmental dust removal ash, sintering dust, pellet dust, blast furnace dust , Converter dust, electric furnace dust, steel slag, steel rolling dust, iron scale, iron red, coking dust and other solid waste, calcium oxides include quicklime, limestone, dolomite One or more mixtures, magnesium-containing oxides include single or multiple mixtures of magnesite, light burnt dolomite, serpentine, and dolomite.

[0058] (3) The mixture is dried and dehydrated, and the water content of the dried mixture is 2 wt%.

[0059] (4) Carry out ...

Embodiment 3

[0066] Embodiment 3 of the present invention discloses a method for processing metallurgical solid waste, which specifically includes the following steps:

[0067] (1) first crush and grind metallurgical solid waste, and sieve through a 6mm sieve;

[0068] (2) Weigh metallurgical solid waste, calcium-containing oxides and magnesium-containing oxides respectively according to the mass ratio of 90:5:5; among them, metallurgical solid waste includes environmental dust removal ash, sintering dust, pellet dust, blast furnace dust , Converter dust, electric furnace dust, steel slag, steel rolling dust, iron scale, iron red, coking dust and other solid waste, calcium oxides include quicklime, limestone, dolomite One or more mixtures, magnesium-containing oxides include single or multiple mixtures of magnesite, light burnt dolomite, serpentine, and dolomite.

[0069] (3) The mixture is dried and dehydrated, and the water content of the dried mixture is 2 wt%.

[0070] (4) Carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com