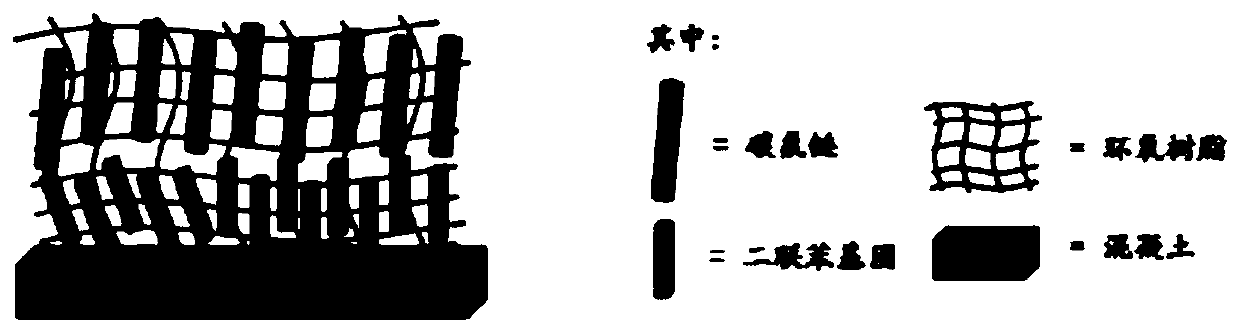

Double liquid crystal structure toughened epoxy resin water-proof paint and preparation method thereof

A technology of tough epoxy resin and epoxy resin, which is applied in the field of epoxy resin waterproof coating and its preparation, can solve the problems of complex process required to improve toughness and inability to effectively improve the toughness of epoxy resin, and achieve the effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

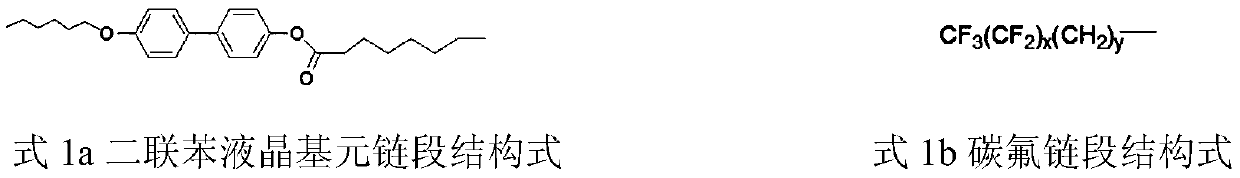

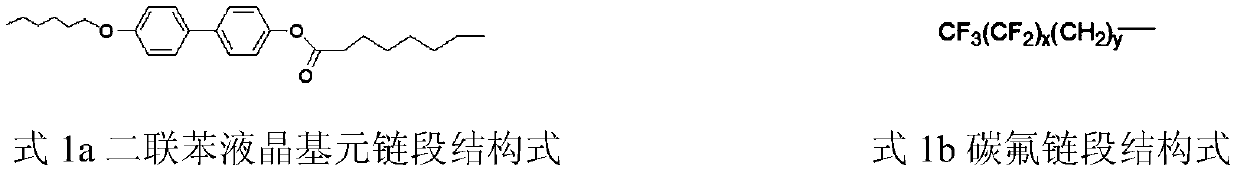

[0087] (1) Dissolve 100g epoxy resin E44 in a flask containing 500g dichloromethane, add 8g dicyclohexylcarbodiimide and 2g 4-dimethylaminopyridine, stir for 10min, add 25g diphenyl liquid crystal base After the reaction for 8 hours, the liquid crystal cell modified epoxy resin A1 was separated using a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether as the eluent. 100g epoxy resin E44 and 30g hydroxyl functional group fluorine chain extender Dissolve Z-DOL in a flask containing 500g of dichloromethane, add 1g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1g of 4-dimethylaminopyridine, and stir After 10 minutes, 30g of 2H, 2H, 3H, 3H-perfluorononanoic acid was added and reacted at room temperature. After 24 hours of reaction, a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether were used as the eluent to separate the fluorocarbon chain modified epoxy resin A2.

[0088] (2) In the beaker, add 40g cu...

Embodiment 2

[0099] (1) Dissolve 100g epoxy resin E51 in a flask containing 500g dichloromethane, add 6g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 2g 4- Dimethylaminopyridine, after stirring for 10 minutes, add 14 g of diphenyl mesogen, and react at room temperature. After 8 hours of reaction, use a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether as the eluent to separate the mesogen modified epoxy resin A1; 100g epoxy resin E51 and 45g hydroxyl functional group fluorine chain extender Z-DOL was dissolved in a flask containing 500g of dichloromethane, 6g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 2g of 4-dimethylaminopyridine were added and stirred After 10 minutes, 16g of perfluoroheptanoic acid was added and reacted at room temperature. After 24 hours of reaction, a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether were used as the eluent to separate the fluorocarbon chain modified...

Embodiment 3

[0111] (1) Dissolve 100g epoxy resin E44 in a flask containing 500g dichloromethane, add 7g N,N'-diisopropylcarbodiimide and 2g 4-dimethylaminopyridine, stir for 10min, add 25g of biphenyl mesogen, react at room temperature. After 24 hours of reaction, use a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether as the eluent to separate the mesogen modified epoxy resin A2; 100g epoxy resin E44 and 40g hydroxyl functional group fluorine chain extender Dissolve Z-DOL in a flask containing 500g of dichloromethane, add 7g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 2g of 4-dimethylaminopyridine, and stir for 10 minutes Then, 20g of perfluoropentanoic acid was added and reacted at room temperature. After 8 hours of reaction, a chromatographic column and a mixed solvent of ethyl acetate and petroleum ether were used as the eluent to separate the fluorocarbon chain modified epoxy resin A1.

[0112] (2) In the beaker, add 40g curing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com