A multi-metal injection molding system and method with on-line adjustable alloy composition

A technology of injection molding and alloy composition, applied in the field of metallurgy, can solve the problems of inability to realize on-line adjustment of alloy composition, increase of waste at the head and tail, decrease of yield, etc., to improve filling stability, efficiency and yield, and uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

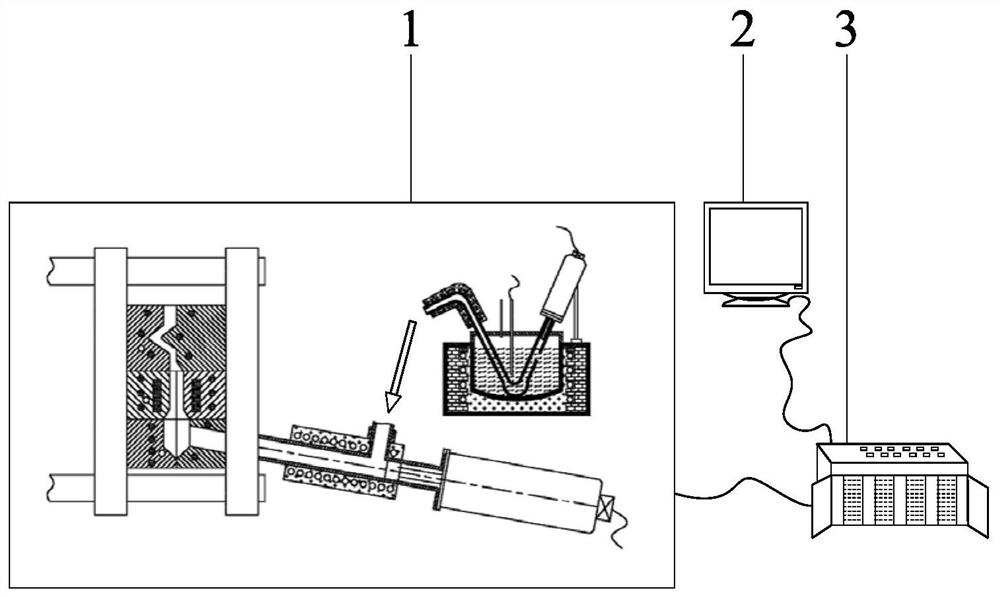

[0048] The structure of the multi-metal injection molding system with online adjustable alloy composition is as follows: figure 1 As shown, it consists of a mechanical part and a control part;

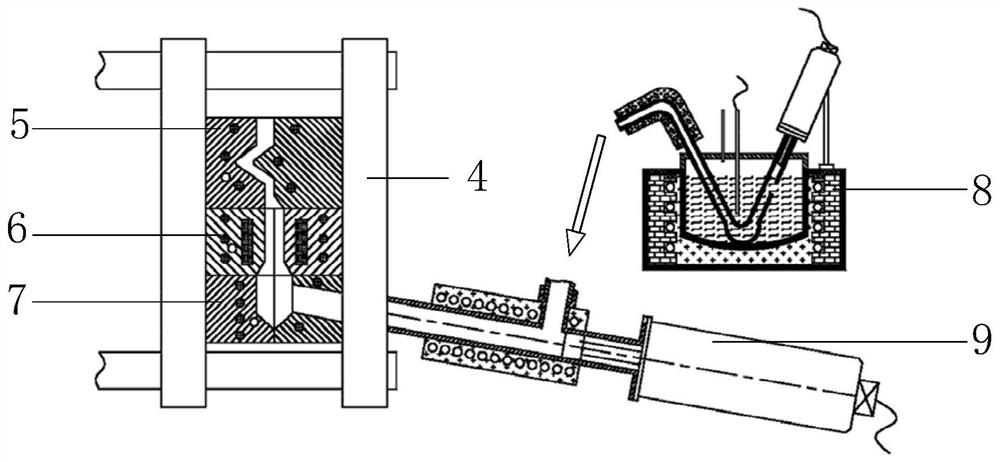

[0049] The structure of the mechanical part is as figure 2 As shown, it includes a plurality of injection devices 8, a plurality of injection devices 9, a transition module 7, a mixing module 6 and a mold 5;

[0050] The control part is composed of the main control computer and the operation console equipped with PLC;

[0051] The mold 5, the mixing module 6 and the transition module 7 are simultaneously located in the fixed plate 4 and arranged from top to bottom;

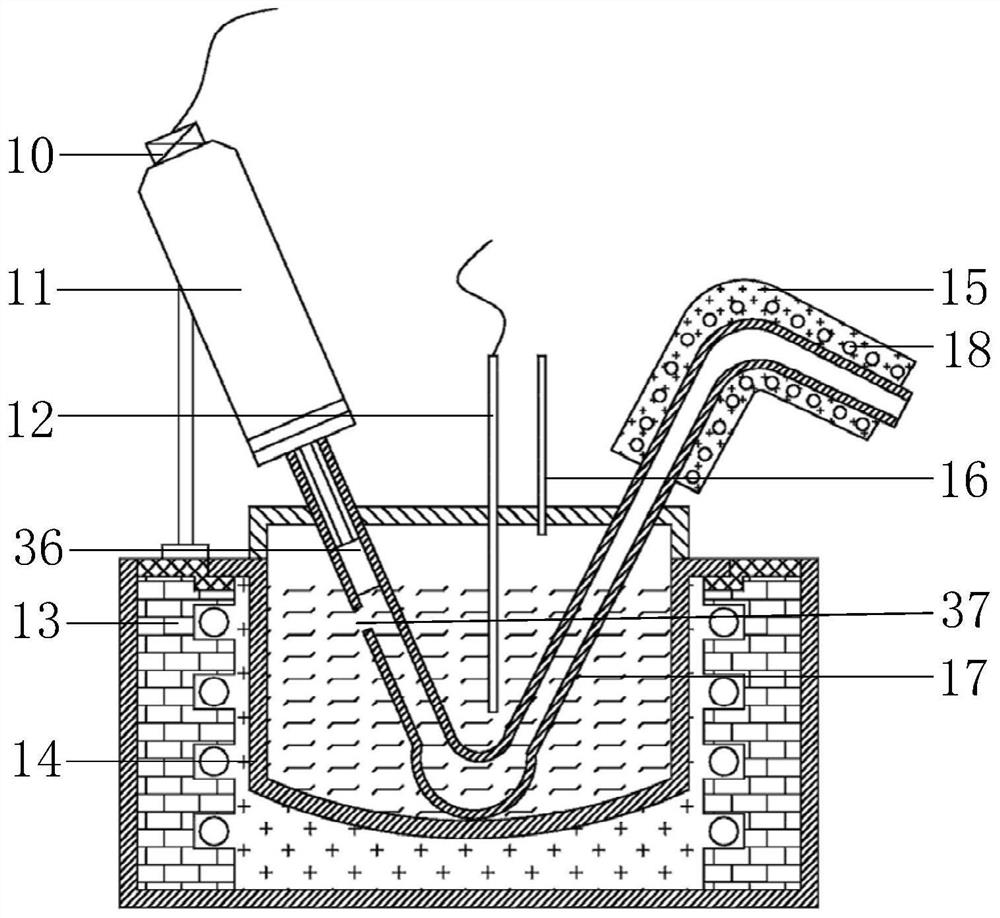

[0052] Transition module 7 is structured as Figure 6 and 7 As shown; a plurality of transition chamber inlet passages 30 are provided to communicate the transition chamber 29 with the outside of the transition module 7; each transition chamber inlet passage 30 is downward from the transition chamber 7 to the outside,...

Embodiment 2

[0089] Adopt the device of embodiment 1, replace the mold and get rid of the residual metal in the transition chamber and the mixing chamber, and reset the preset temperature according to the above-mentioned method according to the melting point temperature and mass percentage of each alloy raw material, according to the solidification state density of each alloy composition and The mass percentage resets the propulsion speed as described above, and then performs multi-metal injection molding again;

[0090] Method is with embodiment 1, and difference is:

[0091] (1) According to the composition of the target alloy ZL105 alloy casting, the mass percentages of the three alloy raw materials are 55%, 15% and 35% respectively;

[0092] (2) Industrial pure aluminum is M 0 , more than 50% of the total mass of all alloy raw materials, expressed in M 0 The melting point temperature of industrial pure aluminum is 660°C as the preset temperature;

[0093] (3) The propulsion speeds o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com