Synthesis gas methanation catalyst and preparation method thereof

A catalyst and gas methane technology, which is applied in the field of synthesis gas methanation catalyst and its preparation to achieve the effects of increasing the concentration of reactants, good dispersion and good carbon-accommodating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

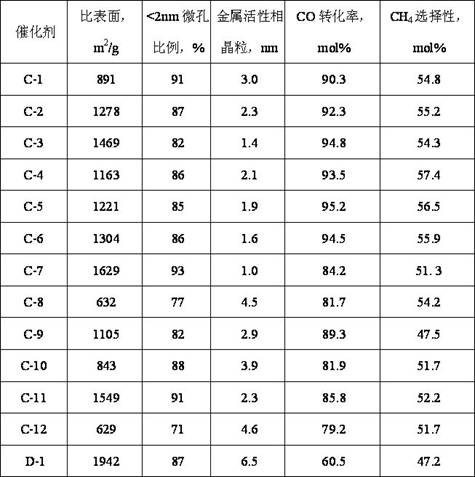

Examples

Embodiment 1

[0046] Weigh 24.78g of nickel nitrate hexahydrate, 4.68g of lanthanum nitrate hexahydrate and 6.89g of potassium nitrate in 94mL of deionized water to obtain solution A; weigh 32.74g of citric acid and dissolve in 81mL of deionized water; place solution A in In a water bath at 80°C, under stirring conditions, add the citric acid solution dropwise to solution A. After the dropwise addition, continue to stir until the solution is viscous, and then put it in an oven and dry it at 150°C for 6 hours. The obtained sample Then calcined at 700°C for 6h to obtain a composite oxide.

[0047] Grind 100g of petroleum coke to powder, then mix it evenly with the above-mentioned composite oxide and 200g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, vacuumize it, and raise the temperature to 400°C, keep it constant for 60min, then pass nitrogen gas to normal pressure, continue to raise the temperature to 800°C for 20min under the condit...

Embodiment 2

[0050] Weigh 37.16g of nickel nitrate hexahydrate, 6.23g of lanthanum nitrate hexahydrate and 12.92g of potassium nitrate in 153mL of deionized water to obtain solution A; weigh 73.66g of citric acid and dissolve in 146mL of deionized water; place solution A in In a water bath at 80°C, under stirring conditions, add the citric acid solution dropwise to solution A. After the dropwise addition, continue to stir until the solution is viscous, and then put it in an oven and dry it at 150°C for 6 hours. The obtained sample Then calcined at 700°C for 6h to obtain a composite oxide.

[0051] Grind 100g of petroleum coke to powder, then mix it evenly with the above-mentioned composite oxide and 300g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, vacuumize it, and raise the temperature to 500°C, keep it constant for 40min, then pass nitrogen gas to normal pressure, and continue to heat up to 800°C for 20min under the condition of ...

Embodiment 3

[0054] Weigh 49.55g nickel nitrate hexahydrate, 7.79g lanthanum nitrate hexahydrate and 20.67g potassium nitrate and dissolve in 222mL deionized water to obtain solution A; weigh 130.95g citric acid and dissolve it in 216mL deionized water; place solution A in In a water bath at 80°C, under stirring conditions, add the citric acid solution dropwise to solution A. After the dropwise addition, continue to stir until the solution is viscous, and then put it in an oven and dry it at 150°C for 6 hours. The obtained sample Then calcined at 700°C for 6h to obtain a composite oxide.

[0055] Grind 100g of petroleum coke into powder, then mix it evenly with the above-mentioned composite oxide and 400g of potassium hydroxide, place it in a microwave heating furnace with a microwave frequency of 2450MHz, vacuumize it, and raise the temperature to 400°C, keep it constant for 60min, then pass nitrogen gas to normal pressure, continue to raise the temperature to 900°C for 10min under the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com