A notch part local stress-strain calculation method under a high-temperature multi-axis load

A stress-strain and calculation method technology, which is applied in calculation, special data processing applications, instruments, etc., can solve the problems of time-consuming, large amount of calculation for strain analysis, etc., and achieve the effect of reducing human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

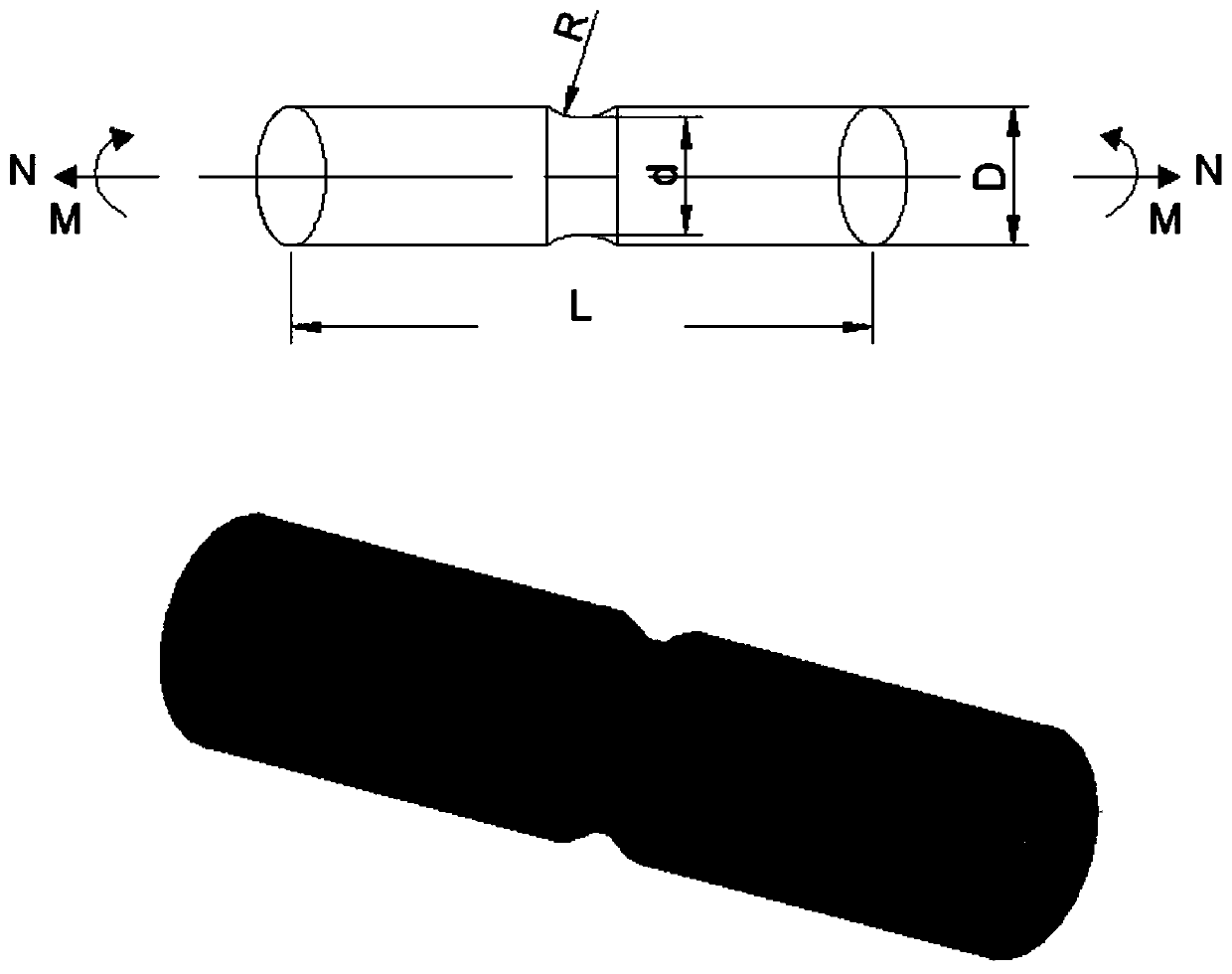

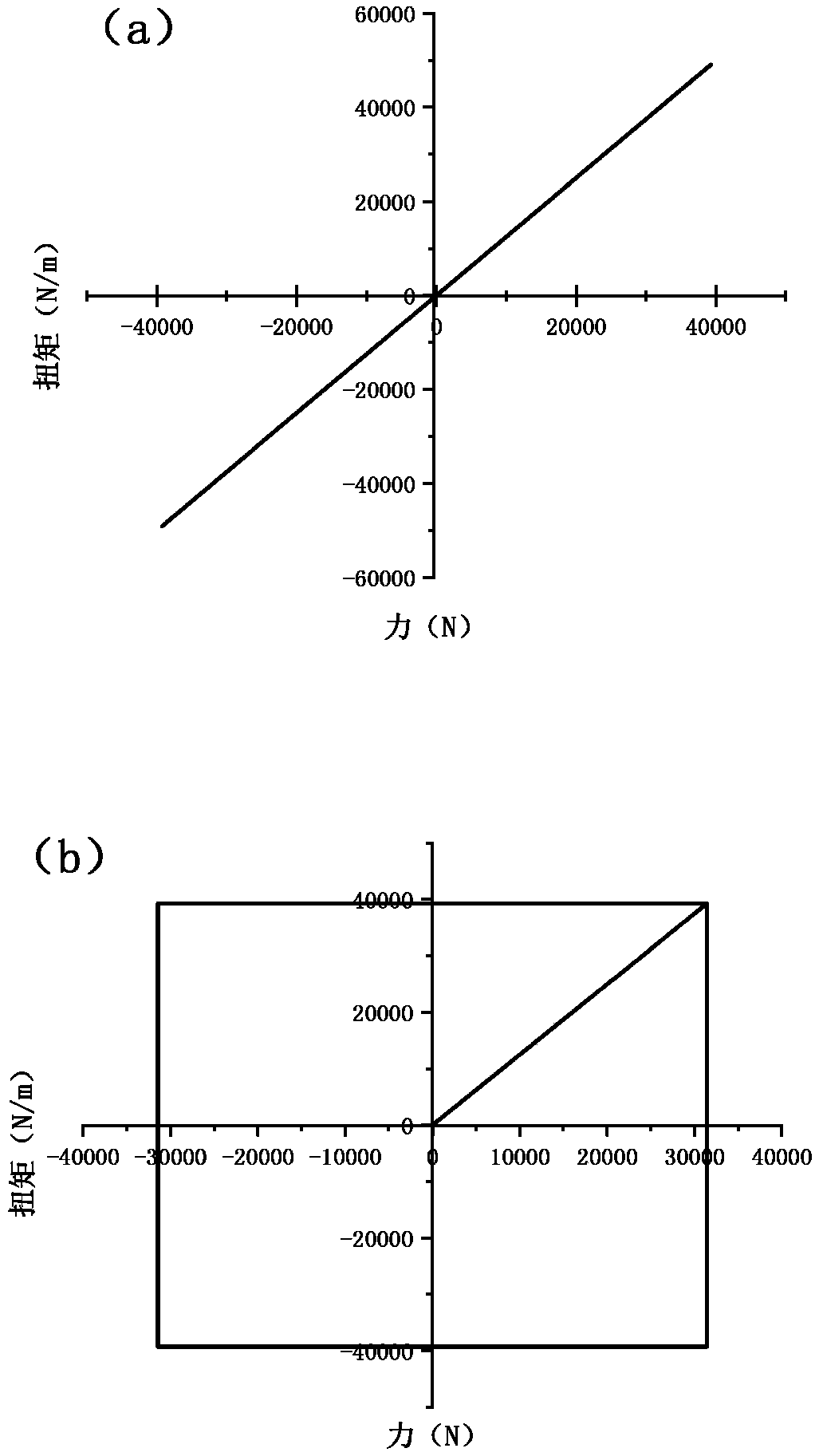

[0051] The present invention has been further illustrated by finite element simulation, and the theoretical stress concentration factors in various directions of the root of the notch are simulated by finite element, and the structural diagram of the engineering test piece and the finite element model are as follows: figure 1 shown. The theoretical stress concentration factors in the three directions at the root of the notch are calculated by finite element simulation to be 1.95, 0.34 and 1.4, respectively. The material constants in the constitutive model are shown in Table 1. The material constants are fitted by uniaxial tests. The test material is a nickel-based superalloy GH4169, which is a turbine disk material of an aeroengine, and the test temperature is 650 °C.

[0052] Table 1 Material constants

[0053] E

k

Z

n

Q

b

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com