Detecting module and detecting method for abrasion of cutting edge of diamond tool

A diamond tool and detection module technology, which is applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of small scanning range, difficulty in high integration, and difficulty in large-scale wear observation, so as to improve consistency and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

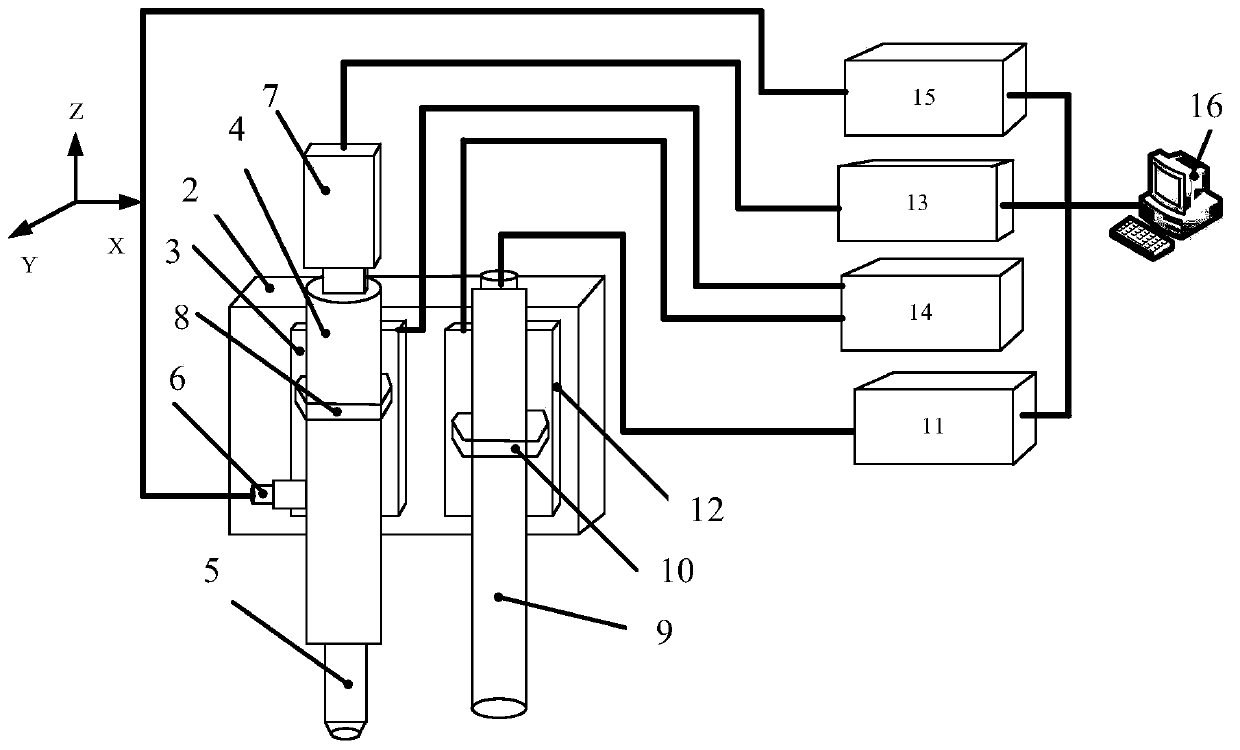

[0037] A diamond tool cutting edge wear detection module, such as figure 1 As shown, it includes 3R high-precision pneumatic conversion fixture 1, adapter plate 2, microscope tube Z-direction motion table 3, single-tube zoom microscope tube 4, microscope objective lens 5, coaxial point light source 6, CCD camera 7, lens tube Fixture 8, spectral confocal sensor 9, spectral confocal sensor fixture 10, spectral confocal controller 11, spectral confocal sensor Z-direction motion table 12, image acquisition card 13, motion controller 14, light source controller 15 and PC processing machine16.

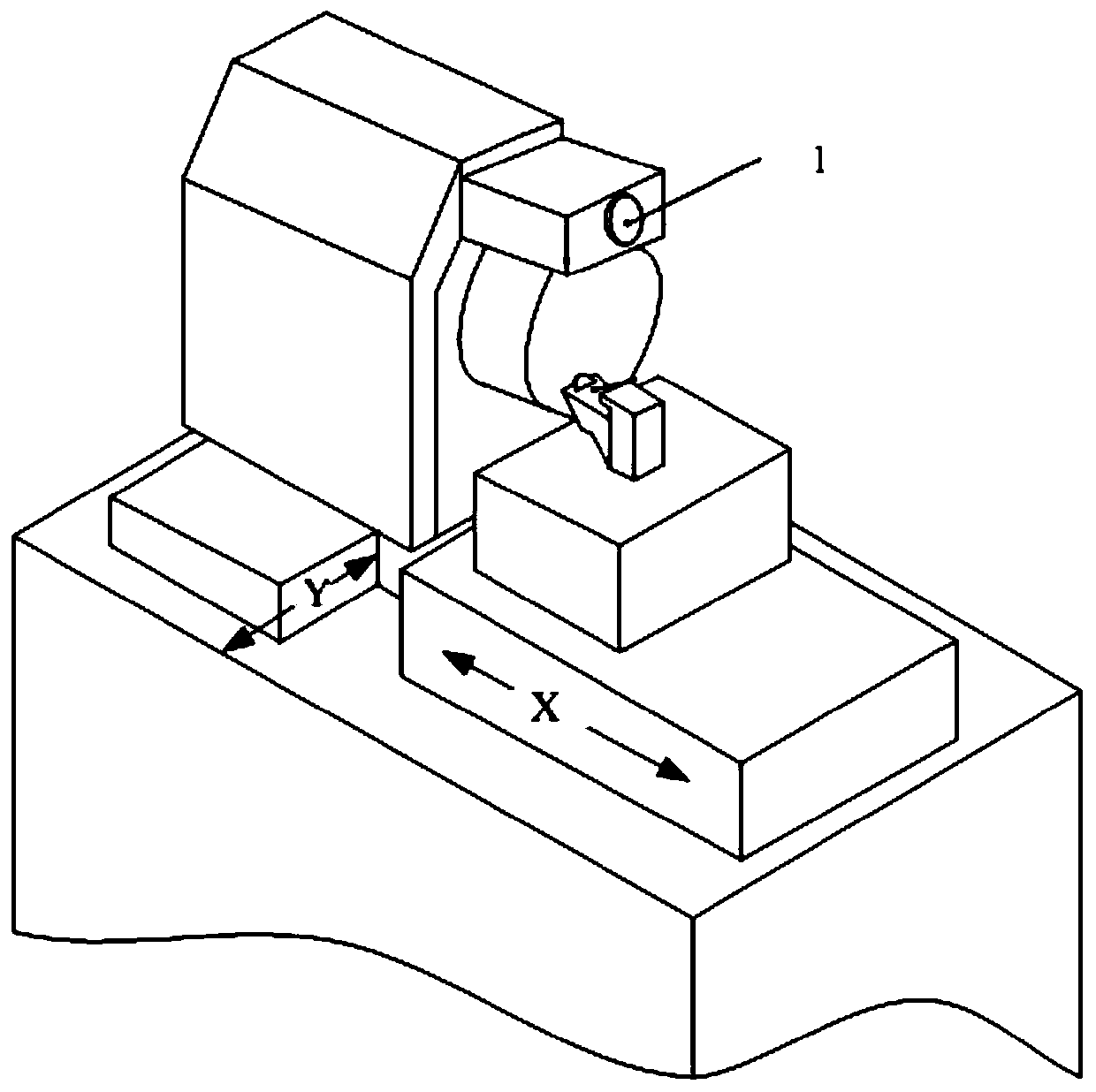

[0038] Such as figure 2 As shown, in this embodiment, the 3R high-precision pneumatic conversion fixture 1 is a pneumatic clamping method, the repeat positioning accuracy is 1 μm, and the effective load is 10 kg. The base of the 3R high-precision pneumatic conversion fixture 1 is assembled on the machine tool.

[0039] In this embodiment, the coaxial point light source 6 is a white light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com