Nano-diamond-containing lithium ion battery pole piece and preparation method thereof

A nano-diamond and lithium-ion battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of accelerated battery capacity decay, SEI film damage, low heat production, etc., to reduce internal resistance, heat production, and volume Small expansion and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method that the present invention proposes containing the lithium ion battery pole piece of nano-diamond, comprises the following steps:

[0024] S1. According to the conditions that the total solid content of the conductive paste is 6% and the weight ratio of additives, ion-implanted nano-diamonds, and conductive carbon nanotubes is 15:30:55, weigh the additives and ion-implanted nano-diamonds respectively. The quality of diamond, carbon nanotubes and solvent NMP, and then the weighed additives are mixed with NMP to obtain a mixed solution, and then ion-implanted nano-diamonds are added to the mixed solution, and the ultrasonic frequency of 80KHz is dispersed for 15 minutes to form Suspension, finally add conductive agent carbon nanotubes and mix evenly, and then treat with 40KHz ultrasonic frequency for 15min to make conductive paste;

[0025] S2. Dissolve HSV 900 in NMP to form a binder glue with a solid content of 8%. The ratio of the solid mas...

Embodiment 2

[0028] A kind of preparation method that the present invention proposes containing the lithium ion battery pole piece of nano-diamond, comprises the following steps:

[0029] S1. First, according to the conditions that the total solid content of the conductive paste is 8% and the weight ratio of additives: nano-diamond: conductive agent carbon nanotubes is 10:40:50, weigh the additives and ion-implanted nano-diamond powder respectively , carbon nanotubes and solvent NMP, and then mix the weighed additive with NMP to obtain a mixed solution, and then add ion-implanted nano-diamond powder to the mixed solution and disperse it with an ultrasonic frequency of 80KHz for 15 minutes to form a suspension. Turbid liquid, finally add conductive agent carbon nanotubes and mix evenly, then treat with 40KHz ultrasonic frequency for 20min to make conductive paste;

[0030] S2. Dissolve HSV 900 in NMP to obtain the binder glue according to the ratio of the solid content of the binder glue to...

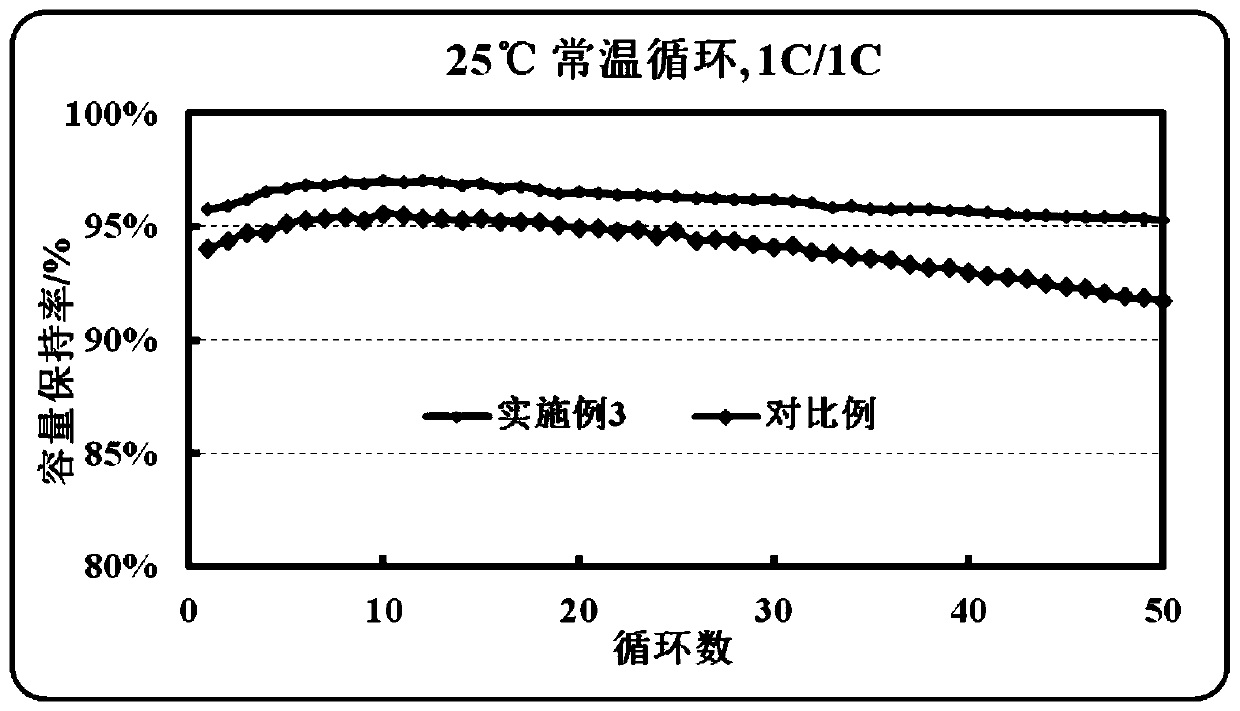

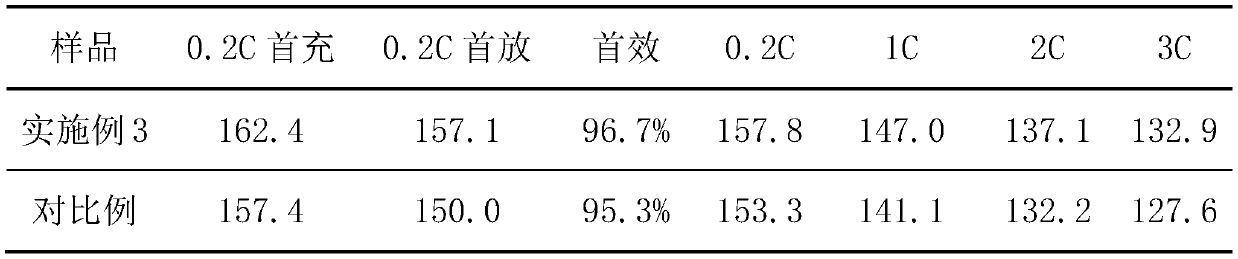

Embodiment 3

[0033] A kind of preparation method that the present invention proposes containing the lithium ion battery pole piece of nano-diamond, comprises the following steps:

[0034] S1. Firstly, according to the design that the total solid content of the conductive paste is 8%, and the weight ratio of additives, ion-implanted nano-diamond powder, and conductive agent carbon nanotubes is 20:20:60, weigh the additives and ion implantation respectively. The quality of the nano-diamond powder, carbon nanotubes and solvent NMP, and then the weighed additives are mixed with NMP evenly, and then the ion-implanted nano-diamond powder is added and dispersed for 15 minutes at an ultrasonic frequency of 80KHz to form a suspension. Finally, add conductive agent carbon nanotubes and mix evenly, and then treat with 40KHz ultrasonic frequency for 20min to make conductive paste;

[0035] S2. Dissolving HSV 900 in NMP to form a binder glue, wherein the solid content of the binder glue is 7%, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com