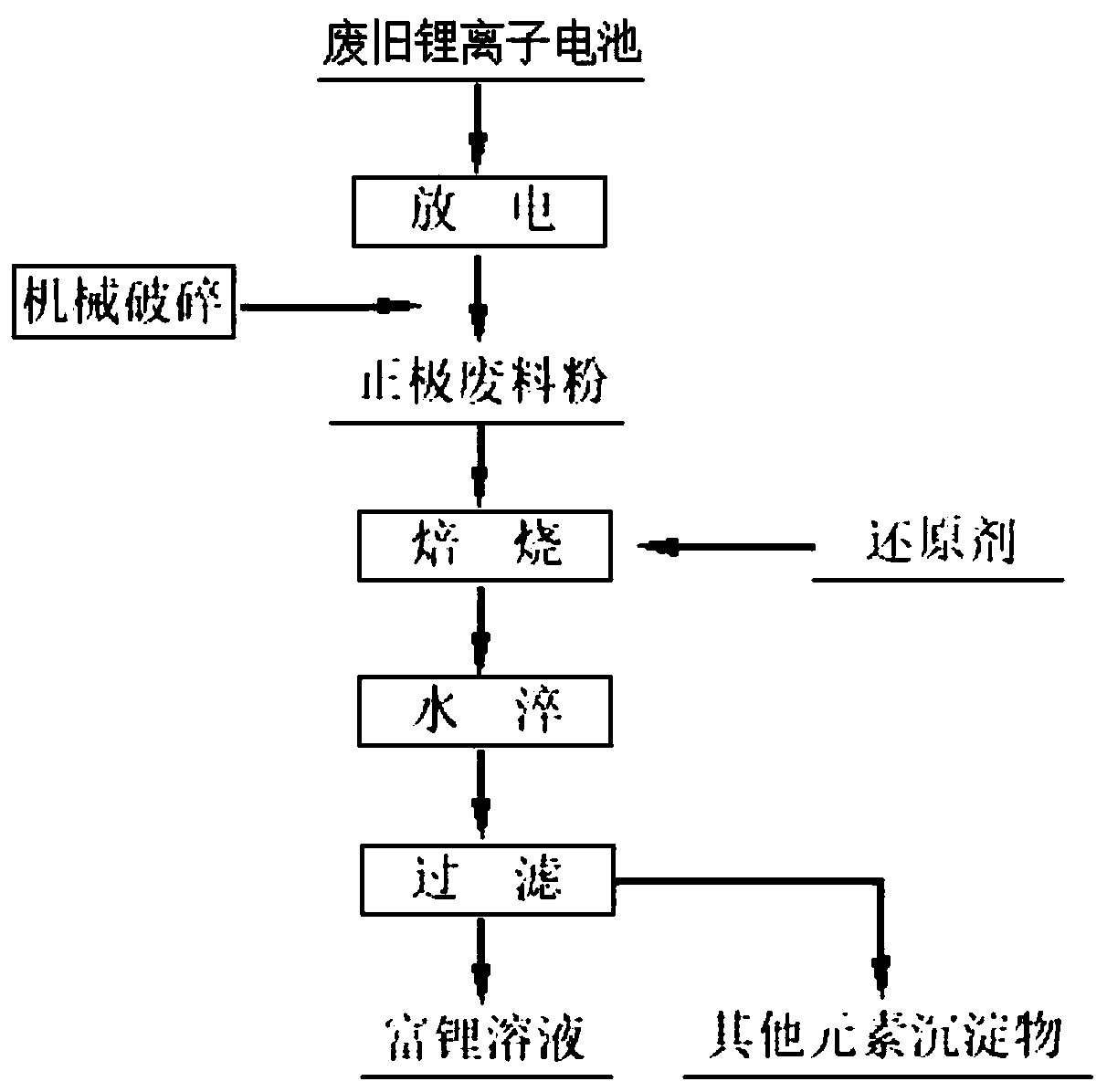

Method for recycling lithium in waste lithium-ion batteries with reduction roasting-water quenching method

A technology of lithium-ion battery and water quenching method, which is applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as complex process, complex process, and increased cost, and achieve simple process and solve process Complex and beneficial to industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Discharge the waste lithium manganate battery and then mechanically crush and sort to obtain positive electrode waste powder; mix the positive electrode waste powder and graphite negative electrode powder evenly to obtain a mixture, and the amount of graphite negative electrode powder added is 30% of the mass of the positive electrode waste powder; mix the mixture Put it into a muffle furnace for reduction roasting; the roasting temperature is 800°C, and the roasting time is 30 minutes; the mixture after reduction roasting is quickly put into water for water quenching, and the water quenching time is 5 minutes, and the lithium in the mixture enters the water to obtain a lithium-rich solution. Lithium is effectively separated from other materials by filtration. The recovery rate of lithium in waste lithium manganate batteries is 93%.

Embodiment 2

[0025] Discharge the waste lithium cobalt oxide battery and then mechanically crush and sieve to obtain the positive electrode waste powder; mix the positive electrode waste powder and charcoal evenly to obtain a mixture, and the amount of charcoal added is 40% of the mass of the positive electrode waste powder; put the mixture into the muffle Reduction roasting is carried out in the furnace; the roasting temperature is 1000°C, and the roasting time is 60 minutes; the mixture after reduction roasting is quickly put into water for water quenching, and the water quenching time is 20 minutes, and the lithium in the mixture enters the water to obtain a lithium-rich solution. It is effectively separated from other materials. The recovery rate of lithium in waste lithium cobalt oxide batteries is 96%.

Embodiment 3

[0027] Discharge the waste nickel-cobalt lithium manganate ternary battery and then mechanically crush and screen to obtain positive electrode waste powder; uniformly mix the positive electrode waste powder and activated carbon to obtain a mixture, and the amount of activated carbon added is 50% of the mass of the positive electrode waste powder; mix the mixture Put it into a muffle furnace for reduction roasting; the roasting temperature is 1200°C, and the roasting time is 180 minutes; the mixture after reduction roasting is quickly put into water for water quenching, and the water quenching time is 30 minutes. The lithium in the mixture enters the water to obtain a lithium-rich solution. Lithium is effectively separated from other materials by filtration. The recovery rate of lithium in the waste nickel-cobalt-lithium manganese oxide ternary battery is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com