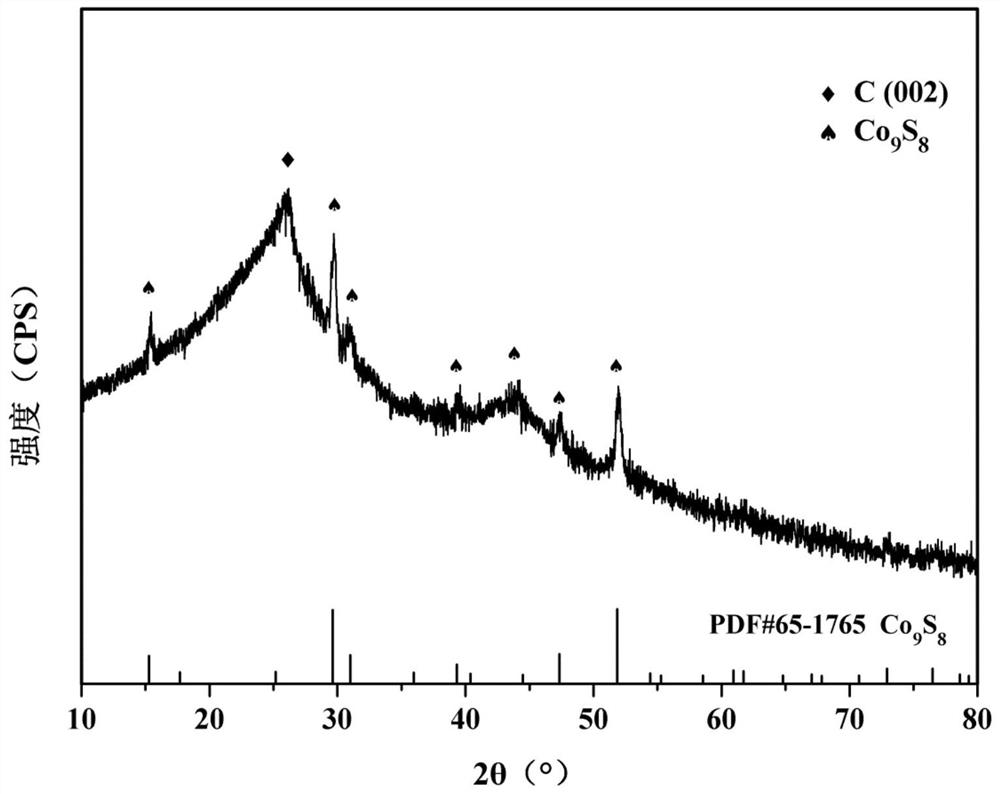

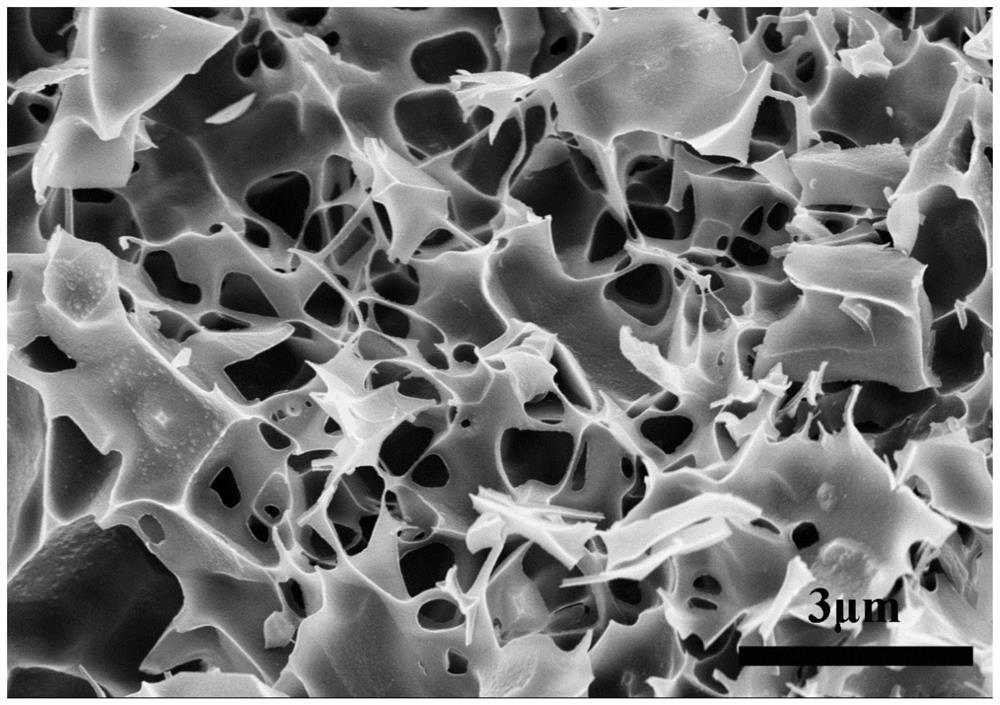

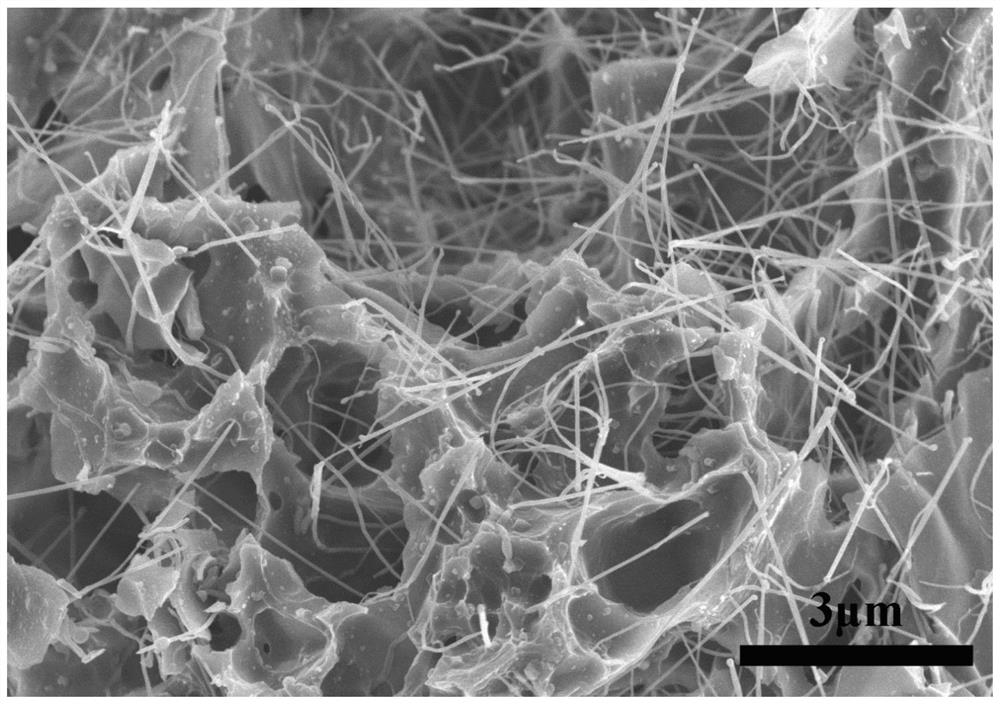

A kind of porous carbon@carbon nanotube absorbing material and its preparation method

A carbon nanotube and wave-absorbing material technology, applied in the field of material science, can solve the problems of large filling amount and unfavorable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing porous carbon@carbon nanotube wave-absorbing material using sodium chloride as a template, comprising the following steps:

[0047] (1) Firstly, 0.9 g of thiourea was dispersed in 12 mL of saturated sodium chloride solution to obtain mixed solution A.

[0048] (2) Then add 0.9g of sucrose into the mixed solution A and disperse evenly to obtain the mixed solution B.

[0049] (3) 0.03g cobalt chloride hexahydrate is added in the mixed solution B to obtain the mixed solution C;

[0050] (4) The mixed solution C was sonicated at 600W for 0.8h, then 100mL of liquid nitrogen was added, and freeze-dried for 24h to obtain solid D;

[0051] (5) The solid D was heated up to 590° C. at 1° C. / min under an argon atmosphere, and then kept for 1.5 h to obtain solid E.

[0052] (6) Grinding the solid E, adding deionized water, ultrasonication at 600W for 4 hours, filtration, and vacuum drying at 75°C for 11 hours to obtain solid F.

[0053] (7) After the solid F...

Embodiment 2

[0055] A method for preparing porous carbon@carbon nanotube wave-absorbing material using sodium chloride as a template, comprising the following steps:

[0056] (1) First, 1 g of thiourea was dispersed in 12 mL of saturated sodium chloride solution to obtain mixed solution A.

[0057] (2) Then add 1 g of sucrose into the mixed solution A and disperse evenly to obtain the mixed solution B.

[0058] (3) 0.03g cobalt chloride hexahydrate is added in the mixed solution B to obtain the mixed solution C;

[0059] (4) The mixed solution C was sonicated at 600W for 1 hour, then 150 mL of liquid nitrogen was added, and freeze-dried for 24 hours to obtain solid D;

[0060] (5) The solid D was heated up to 600° C. at 2° C. / min under an argon atmosphere, and then kept for 2 hours to obtain solid E.

[0061] (6) After grinding the solid E, add deionized water, sonicate at 600W for 5h, filter, and vacuum dry at 80°C for 12h to obtain solid F.

[0062] (7) After the solid F was heated up...

Embodiment 3

[0064] A method for preparing porous carbon@carbon nanotube wave-absorbing material using sodium chloride as a template, comprising the following steps:

[0065] (1) Firstly, 1.1 g of thiourea was dispersed in 12 mL of saturated sodium chloride solution to obtain mixed solution A.

[0066] (2) Then add 1.1 g of sucrose into the mixed solution A and disperse evenly to obtain the mixed solution B.

[0067] (3) 0.03g cobalt chloride hexahydrate is added in the mixed solution B to obtain the mixed solution C;

[0068] (4) The mixed solution C was sonicated at 600W for 1.2h, then 200mL of liquid nitrogen was added, and freeze-dried for 24h to obtain solid D;

[0069] (5) The solid D was heated up to 610° C. at 3° C. / min under an argon atmosphere, and then kept for 2.5 hours to obtain solid E.

[0070] (6) Grinding the solid E, adding deionized water, ultrasonication at 600W for 6 hours, filtration, and vacuum drying at 85°C for 13 hours to obtain solid F.

[0071] (7) The solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com