Preparation method of three-dimensional framework polymer-based high-dielectric composite material based on core-shell structure

A composite material and three-dimensional skeleton technology, which is applied in the field of preparation of polymer-based high-dielectric composite materials, can solve the problems of decreased mechanical properties and processing properties of materials, increased conductive phase loss, and increased loss, and achieves applicability and practicability. Strong, easy-to-operate, simple-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

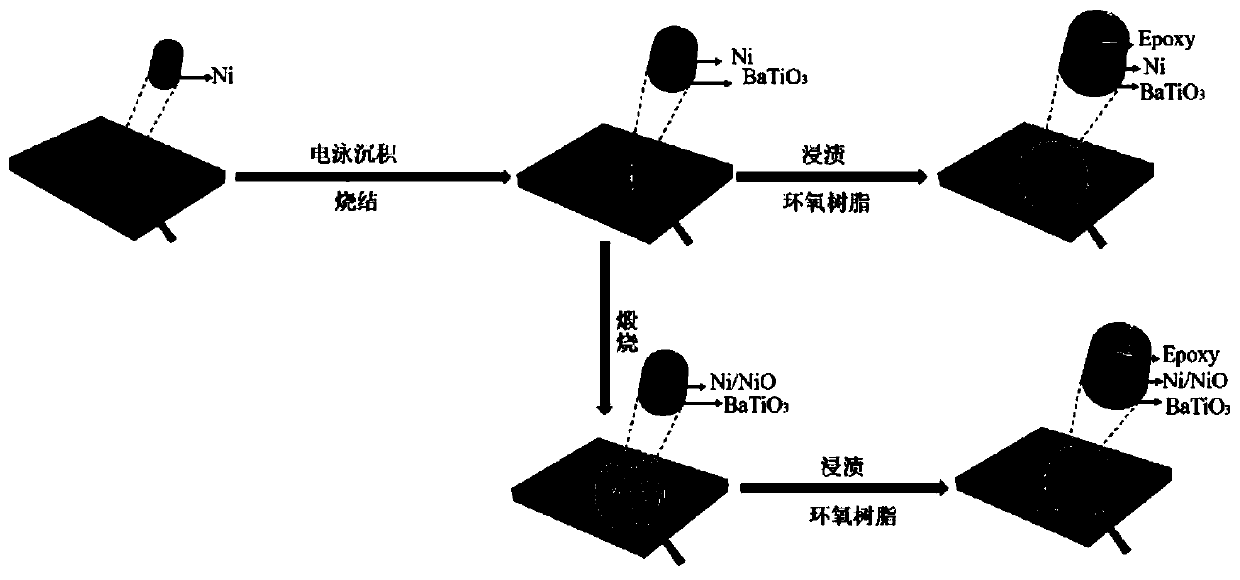

[0038] The preparation method of the polymer-based high dielectric composite material based on the three-dimensional core-shell structure, the preparation process of the nickel foam / barium titanate / epoxy resin composite material:

[0039] 1. Nickel foam pretreatment steps:

[0040] (1) Trim the nickel foam into a block of 2cm×2cm, put it in a beaker, add acetone solution to immerse the nickel foam and ultrasonically clean it for 30min;

[0041] (2) After pouring off the acetone solution, add deionized water, and continue to sonicate for 15 minutes;

[0042] (3) Add absolute ethanol and ultrasonically clean for 15 minutes.

[0043] Two, the preparation steps of foamed nickel / barium titanate composite material:

[0044] (1) Add 1.0 g of barium titanate powder and 0.7 g of polyethyleneimine (PEI) into a beaker, then add 50 mL of isopropanol, stir at room temperature for 4 hours, and then ultrasonicate for 30 minutes to obtain a uniformly dispersed mixed solution of barium titan...

Embodiment 2

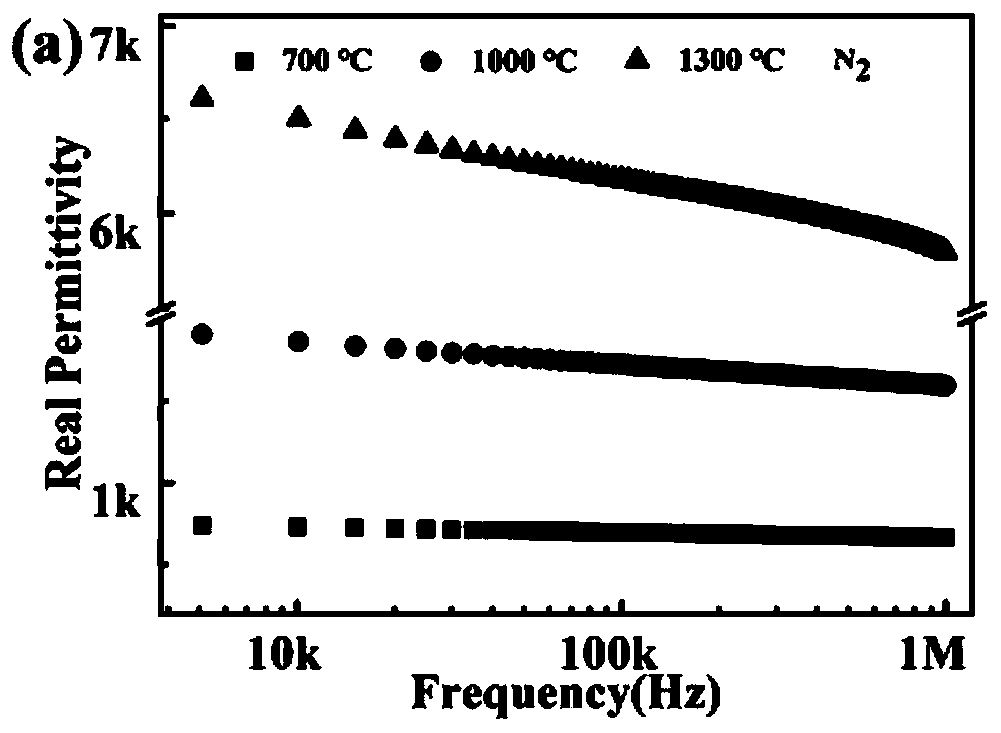

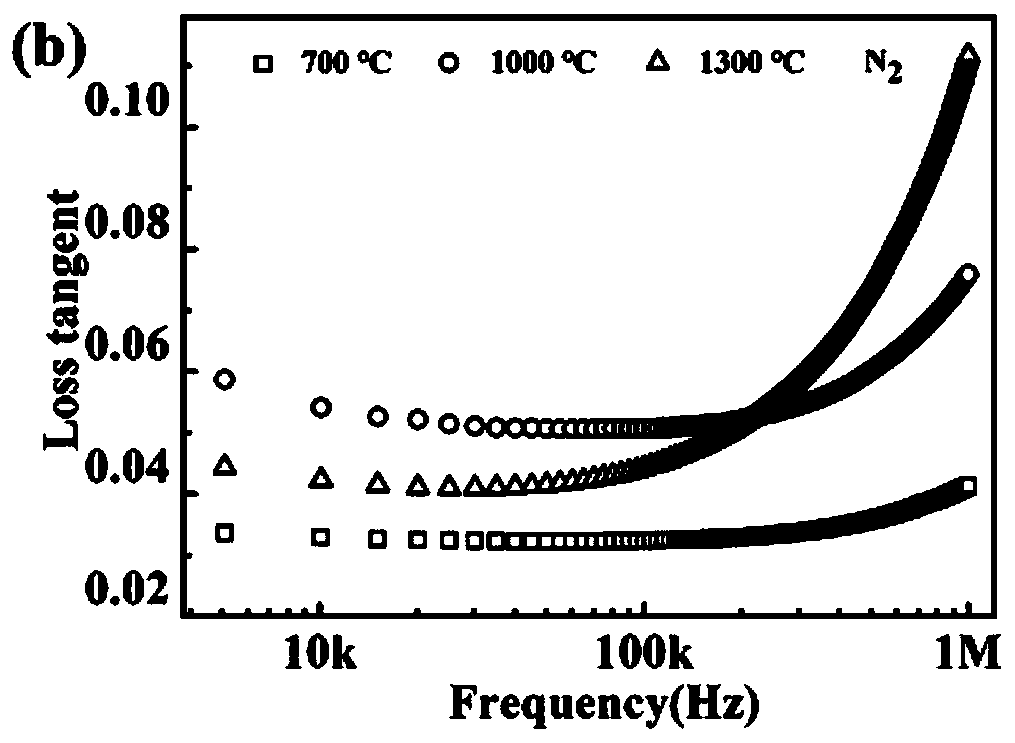

[0051] The preparation method of the polymer-based high dielectric composite material based on the three-dimensional skeleton of the core-shell structure, the preparation process of the nickel foam / barium titanate / epoxy resin composite material, the difference between this embodiment and the embodiment 1 is: controlled sintering The temperature is 1000°C, and the nickel foam / barium titanate / epoxy resin composite material with a sintering temperature of 1000°C is prepared.

Embodiment 3

[0053] The preparation method of the polymer-based high dielectric composite material based on the three-dimensional core-shell structure, the preparation process of the nickel foam / barium titanate / epoxy resin composite material: the difference between this embodiment and the embodiment 1 is: controlled sintering The temperature is 1300°C, and the foam nickel / barium titanate / epoxy resin composite material with a sintering temperature of 1300°C is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com