Preparation method of polymer-based high dielectric composites based on three-dimensional core-shell structure

A composite material and three-dimensional skeleton technology, which is applied in the field of preparation of polymer-based high dielectric composite materials, can solve the problems of increased loss of conductive phase, decreased mechanical properties and processing properties of materials, increased loss, etc., and achieves easy operation and applicability and the effect of strong practicability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

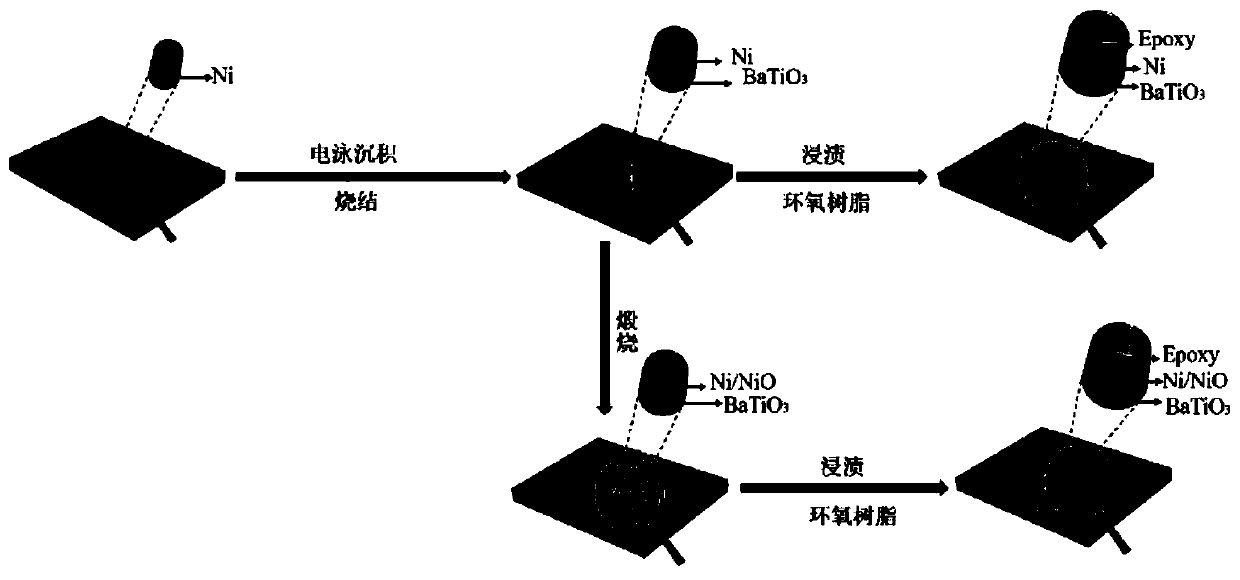

[0038] The preparation method of the polymer-based high-dielectric composite material based on the three-dimensional core-shell structure, the preparation process of the foamed nickel / barium titanate / epoxy resin composite material:

[0039] 1. Pretreatment steps of nickel foam:

[0040] (1) Trim the foamed nickel into a block of 2cm×2cm, put it in a beaker, add acetone solution to submerge the foamed nickel for ultrasonic cleaning for 30 minutes;

[0041] (2) Pour off the acetone solution and add deionized water, and continue to sonicate for 15 minutes;

[0042] (3) Add absolute ethanol and ultrasonic for 15 minutes for cleaning.

[0043] 2. Preparation steps of foamed nickel / barium titanate composite material:

[0044] (1) Add 1.0g of barium titanate powder and 0.7g of polyethyleneimine (PEI) into a beaker, then add 50mL of isopropanol, stir for 4h at room temperature, and then ultrasonic for 30min to obtain a uniformly dispersed barium titanate mixed solution;

[0045] (2) Electrophores...

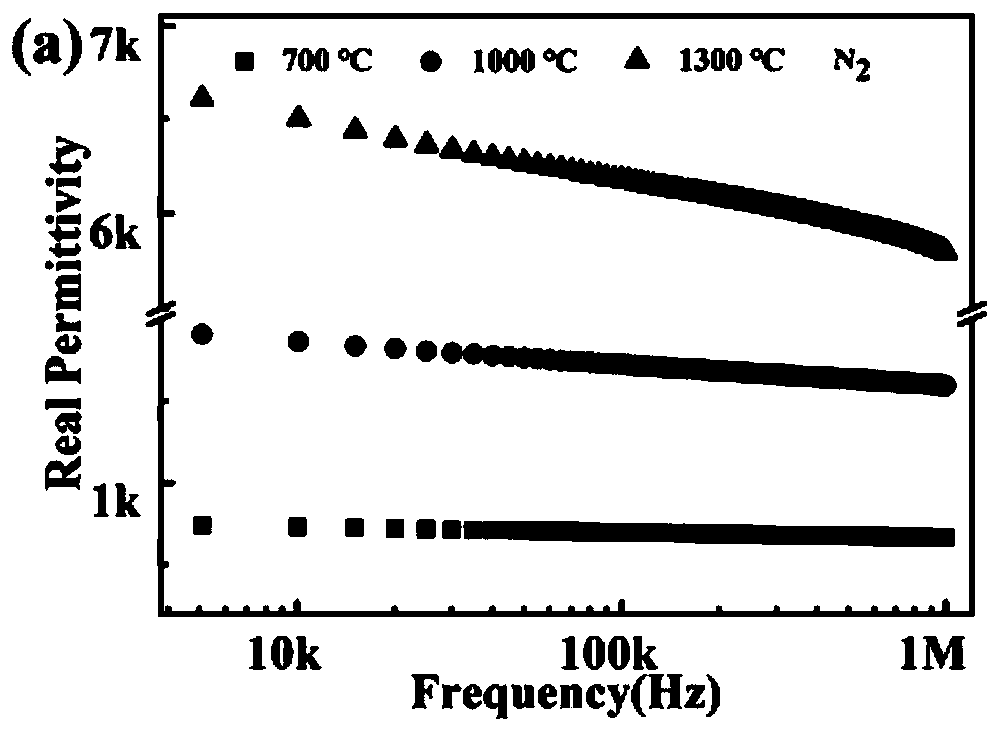

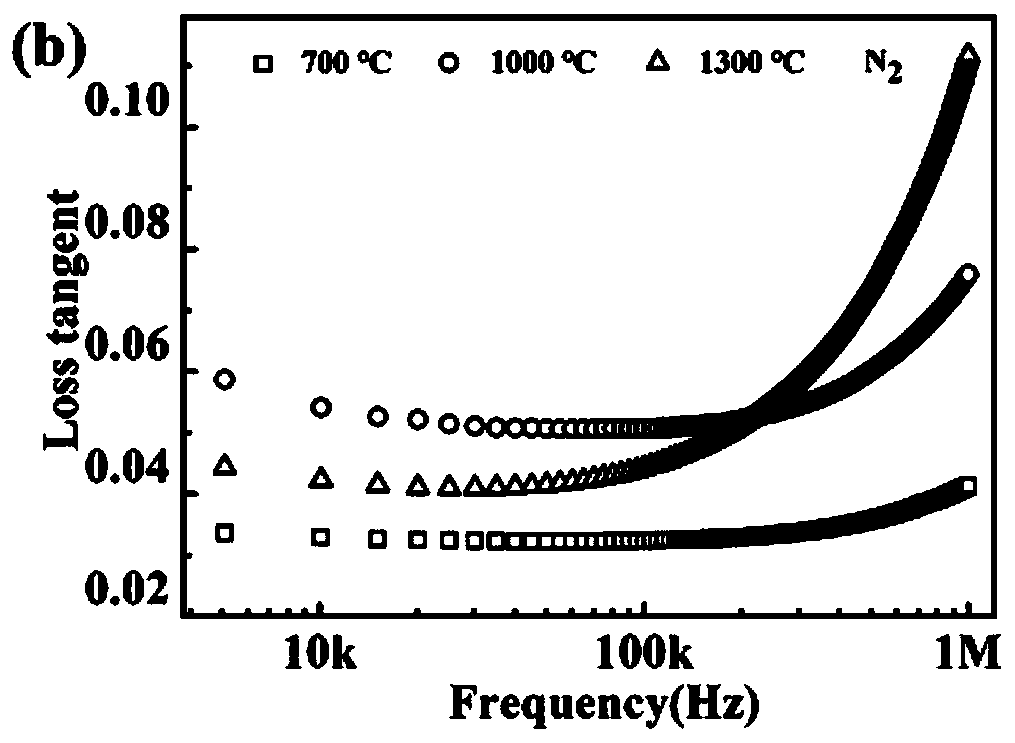

Embodiment 2

[0051] The preparation method of the polymer-based high-dielectric composite material based on the three-dimensional core-shell structure, and the preparation process of the foamed nickel / barium titanate / epoxy resin composite material. Compared with Example 1, the difference between this embodiment is: controlled sintering The temperature is 1000°C, and a foamed nickel / barium titanate / epoxy resin composite material with a sintering temperature of 1000°C is prepared.

Embodiment 3

[0053] The preparation method of the polymer-based high-dielectric composite material based on the three-dimensional core-shell structure, and the preparation process of the foamed nickel / barium titanate / epoxy resin composite material: Compared with Example 1, the difference lies in: controlled sintering The temperature is 1300°C, and a foamed nickel / barium titanate / epoxy resin composite material with a sintering temperature of 1300°C is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com