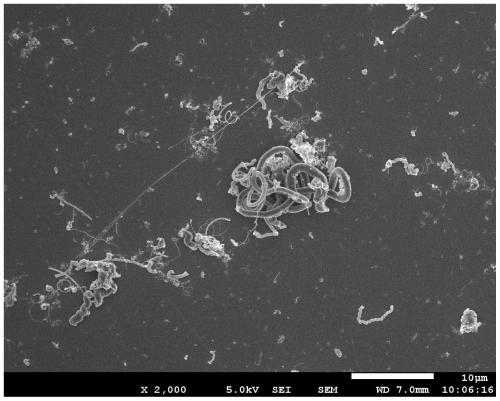

Spiral carbon nanotube prepared through molten salt method and preparation method and application thereof

A carbon nanotube and helical technology, which is applied in the field of preparation of helical carbon nanotubes, can solve the problems of complex preparation methods, low product purity, and long time consumption, and achieve excellent hydrogen and oxygen evolution performance, large specific surface area, and good mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of Mn@N-CN-1 (no molten salt)

[0043] Preparation of Mn@N-CNT-1: Dissolve 0.2g of manganese nitrate and 1.562g of melamine in 40mL of ethanol, stir ultrasonically for 30 minutes, then spin evaporate at 45°C for 1h, and evaporate the ethanol to obtain a solid sealant. Put the obtained solid powder into a ceramic crucible, then place it in a tube furnace, pass nitrogen gas into the tube furnace from the inlet of the tube furnace, and after exhausting the air, fix the balloon on the gas outlet of the tube furnace on, to seal the air outlet. The temperature was raised to 800°C at a heating rate of 2.5°C / min and held at this temperature for 180 minutes. Then, at 5°C min -1 The cooling rate cooled the temperature to 30 °C. The resulting product was dissolved in 1M HNO 3 The solution was treated for 24 hours to remove unreacted manganese salts. After acid treatment, it was washed with water until the pH was neutral, and dried at 60 °C for 12 hou...

Embodiment 2

[0044] Example 2: Preparation of Mn@N-CN-2 (without ball milling)

[0045] Preparation of Mn@N-CNT-2: 0.2 g of manganese nitrate and 1.562 g of melamine were dissolved in 40 mL of ethanol, stirred ultrasonically for 30 minutes, and then rotated at 45 °C for 1 h to evaporate the ethanol. The obtained solid powder is simply mixed with 0.3163g of calcium chloride, and the particle size distribution of the raw materials is 90-200nm. Then put it into a ceramic crucible, and then place it in a tube furnace. Nitrogen is introduced into the tube furnace from the inlet of the tube furnace. After the air is exhausted, the balloon is fixed on the gas outlet of the tube furnace and sealed. gas outlet. The temperature was raised to 800°C at a heating rate of 2.5°C / min and held at this temperature for 180 minutes. Then, at 5°C min -1 The cooling rate cooled the temperature to 30 °C. The resulting product was dissolved in 1M HNO 3 The solution was treated for 24 hours to remove unreacte...

Embodiment 3

[0046] Example 3: Preparation of Mn@N-CNT-3 (ball milled for 6 hours)

[0047] Preparation of Mn@N-CNT-3: 0.2 g of manganese nitrate and 1.562 g of melamine were dissolved in 40 mL of ethanol, stirred ultrasonically for 30 minutes, and then rotated at 45 °C for 1 h to evaporate the ethanol. The obtained solid powder and 0.3163 g of calcium chloride were ball milled in a zirconium casserole at 6000 rpm for 6 hours, and the particle size of the raw material after ball milling was 200-400 nm. After that, put the mixture into a ceramic crucible, then place it in a tube furnace, pass nitrogen gas into the tube furnace from the inlet of the tube furnace, and after the air is exhausted, fix the balloon on the gas outlet of the tube furnace , to seal the air outlet. The temperature was raised to 800°C at a heating rate of 2.5°C / min and held at this temperature for 180 minutes. Then, at 5°C min -1 The cooling rate cooled the temperature to 30 °C. The resulting product was dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com