Photosensitive microcapsule containing photochromic material, and preparation method and application thereof

A technology of photosensitive discoloration and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, application, etc., can solve the problems of insufficient stability and interface polymerization of organic discoloration materials, and achieve good light transmission performance, good mechanical properties, The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

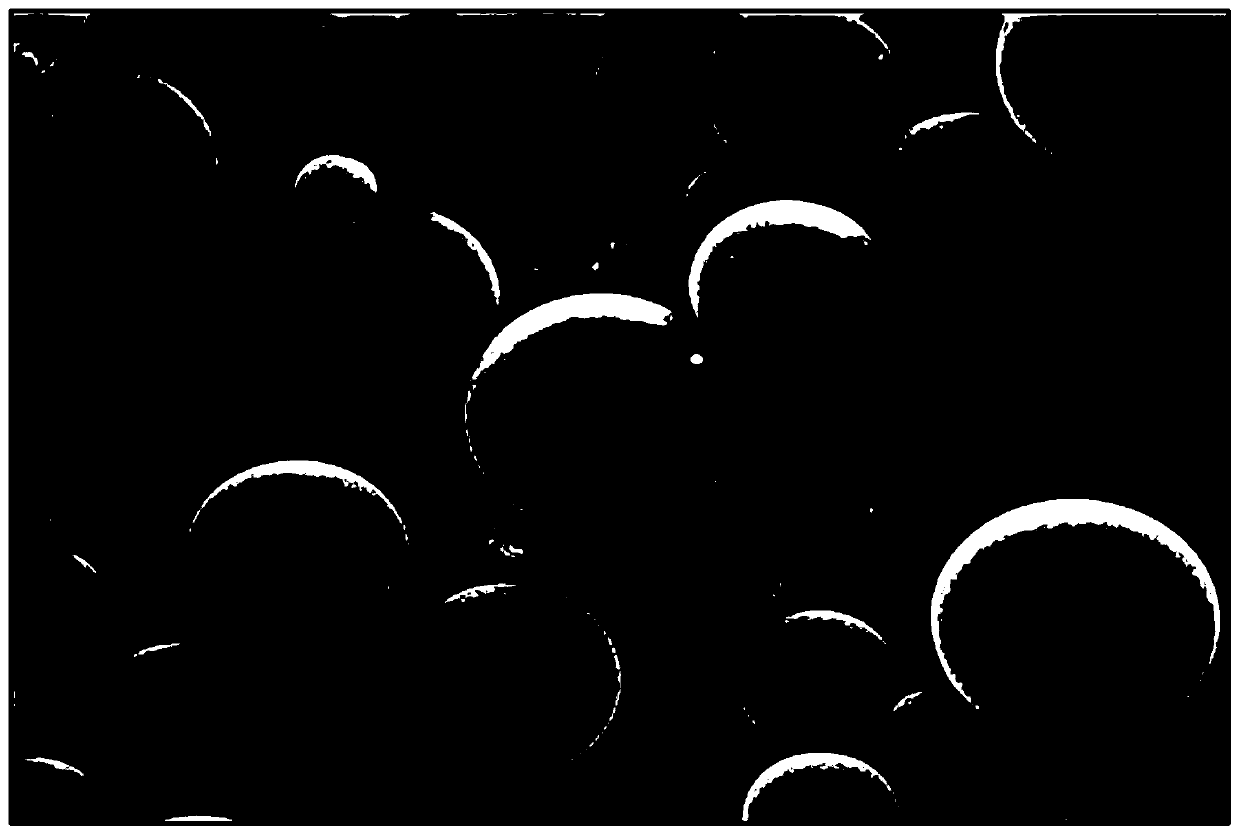

Image

Examples

Embodiment 1

[0049] Add 28 grams of floating refined acid anhydride (FULGIDE, Beijing Donghua Lituo Technology Development Co., Ltd.), 10 grams of pentaerythritol tetraacrylate (PETTA, purchased from Shanghai Fushun International Trade Co., Ltd.) into an internally illuminated 500ml quartz photochemical reactor (L60-45, Beijing Pofeilai Technology Co., Ltd.), heat up to 80 ° C, stir and mix, add 0.25 grams of Span40 (sorbitan palmitic acid monoester, Span-40, Jiangsu Hai'an petrochemical plant) to continue stirring for 30 minutes.

[0050] Add 150ml of deionized water to the above photochemical reactor, stir at a high speed of 3000 rpm for 5 minutes, add 0.5 grams of WB-4784 (benzophenone is the derivative of the parent, and the substituent is 2-hydroxypropoxyl) to the system. -Trimethylammonium chloride salt, AR, Shanghai Fushun Group International Trade Co., Ltd.) and 5ml acetone, continue to stir for 30 minutes, turn on the ultraviolet light source and react with light for 1.5h under th...

Embodiment 2

[0062]30 grams of dithiophene ethylene compound (2-Vinylthiophene, AR, Anaiji Chemical Co., Ltd.) with maleic anhydride as an ene bridge, 8.0 grams of 1,6-hexanediol diacrylate (HDDA, purchased from Shanghai Fushun International Trading Co., Ltd.) was added into the photochemical reactor made of 500ml quartz in the interior illumination type, the temperature was raised to 80° C., stirred and mixed, and when it was cooled to near room temperature, 0.25 gram of Span80 (sorbitan fatty acid ester, Jiangsu Haian Petrochemical Plant, ) to continue stirring for 30 minutes.

[0063] Add 150ml of deionized water into the photochemical reactor, stir at a high speed of 5000 rpm for 5 minutes, add 0.5 grams of WB-4784 (benzophenone is the derivative of the parent, and the substituent is 2-hydroxypropoxy- Trimethylammonium chloride salt, AR, Shanghai Fushun Group International Trade Co., Ltd.) and 5ml acetone, continued to stir for 30 minutes, turned on the ultraviolet light source (wavele...

Embodiment 3

[0066] 28 grams of azobenzene (purchased from Shanghai Shifeng Biotechnology Co., Ltd.), 8 grams of acrylonitrile (purchased from AN Jiangsu Sailbang Petrochemical Co., Ltd.), and 1.2 grams of butyl acrylate (purchased from Pinghu Petrochemical Co., Ltd.) were added to the In an internally illuminated 500ml quartz photochemical reactor, the temperature was raised to 80° C., stirred and mixed, and when it was cooled to near room temperature, 0.3 g of Span40 was added and stirred for 30 minutes.

[0067] Add 150ml of deionized water into the photochemical reactor, stir at a high speed of 3500 rpm for 15 minutes, add 0.5 grams of WB-4698 (benzophenone is the derivative of the parent, and the substituent is 2-sodium methylsulfonate , AR, Shanghai Fushun Group International Trade Co., Ltd.) and 8ml acetone, continue to stir for 30 minutes, turn on the ultraviolet light source (wavelength 365nm) light reaction 2.5h.

[0068] After the light reaction is completed, the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com