Lithium ion battery diaphragm, preparation method thereof, and lithium ion battery

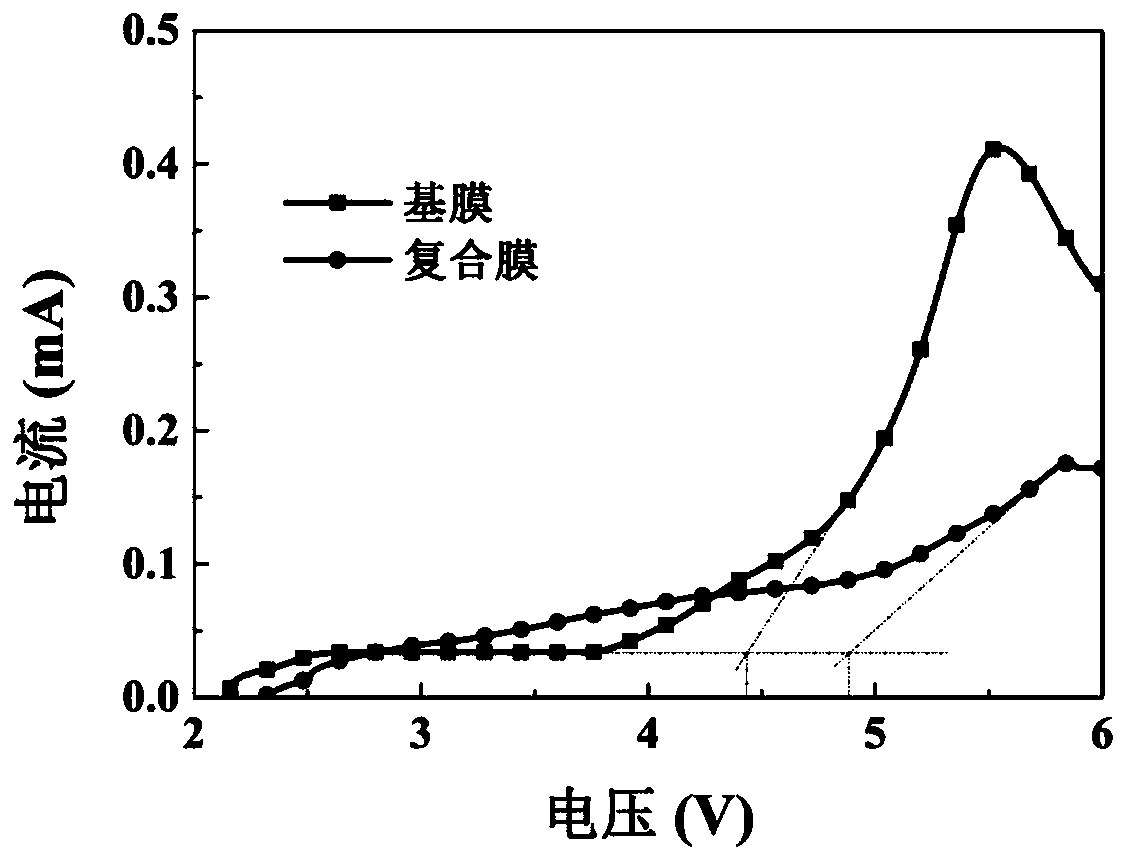

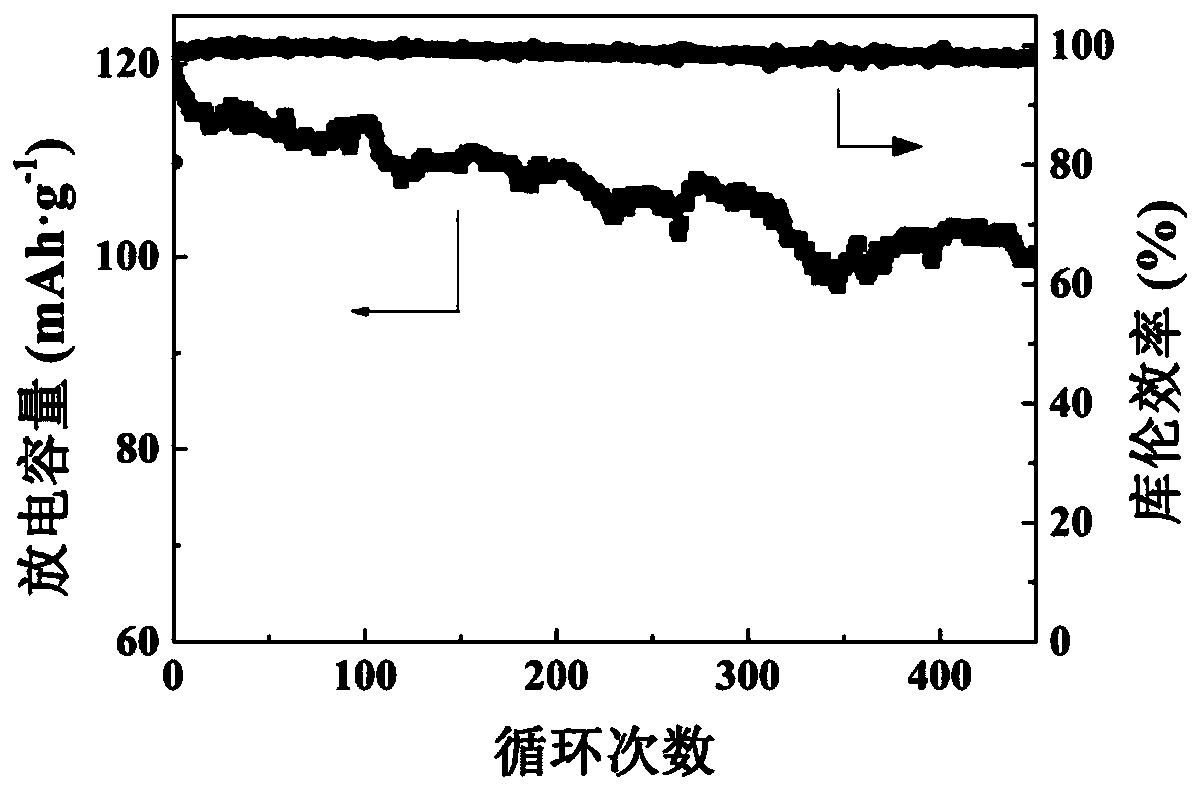

A technology for lithium-ion batteries and diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of reducing the electrochemical performance of batteries, reducing the porosity of diaphragms, and shedding of coating layers, so as to improve electrochemical stability The effect of window, high discharge capacity retention rate, and excellent electrolyte absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of above-mentioned lithium-ion battery diaphragm, comprises the following steps:

[0054] A) performing plasma treatment on the porous polyolefin-based membrane to obtain a pretreated porous polyolefin-based membrane;

[0055] B) first immersing the pretreated porous polyolefin base film in a phenolic solution, then adding silicate substances and aldehyde substances, and reacting to obtain a lithium-ion battery diaphragm.

[0056] In an embodiment of the present invention, the source of the porous polyolefin-based membrane is the same as above, and will not be repeated here.

[0057] In an embodiment of the present invention, before performing the plasma treatment on the porous polyolefin-based membrane, it also includes cleaning and drying the porous polyolefin-based membrane. In some embodiments, the cleaning agent includes acetone or absolute ethanol. The present invention has no special limitation on...

Embodiment 1

[0078] The porous polyolefin base film is a porous polyethylene film, which is prepared from polyethylene through a wet double-drawing process. The thickness of the porous polyethylene film is 25 μm, the porosity is 66%, the electrolyte absorption rate is 183%, and the ion conductivity is 0.206mS·cm -1 .

[0079] The porous polyethylene film is cleaned in acetone, then dried, the dried porous polyethylene film is placed in a plasma cleaning machine, and plasma treatment is performed for 10 minutes to obtain a pretreated porous polyethylene film;

[0080] Add 3-aminophenol into the solvent to prepare a phenolic solution. The solvent includes absolute ethanol with a volume ratio of 80:1:200, ammonia water and water with a mass concentration of 25 wt%.

[0081] Immerse the pretreated porous polyolefin base film in the phenolic solution for 10 minutes, then add tetraethyl orthosilicate and formaldehyde, the molar ratio of 3-aminophenol, tetraethyl orthosilicate and formaldehyde ...

Embodiment 2

[0089] The porous polyolefin base film is a porous polyethylene film, which is prepared from polyethylene through a wet double-drawing process. The thickness of the porous polyethylene film is 25 μm, the porosity is 66%, the electrolyte absorption rate is 183%, and the ion conductivity is 0.206mS·cm -1 .

[0090] The porous polyethylene film is cleaned in acetone, then dried, the dried porous polyethylene film is placed in a plasma cleaning machine, and plasma treatment is performed for 10 minutes to obtain a pretreated porous polyethylene film;

[0091] Add 3-aminophenol into the solvent to prepare a phenolic solution. The solvent includes absolute ethanol with a volume ratio of 60:1:220, ammonia water and water with a mass concentration of 25 wt%.

[0092] Immerse the pretreated porous polyolefin base film in the phenol solution for 10 minutes, then add tetraethyl orthosilicate and formaldehyde, the molar ratio of 3-aminophenol, tetraethyl orthosilicate and formaldehyde is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com