A kind of positive electrode slurry of lithium ion battery and its preparation method and lithium ion battery

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as improving the wettability of powder materials, enhance ion/electron transmission capacity, and reduce battery internal resistance. , Improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

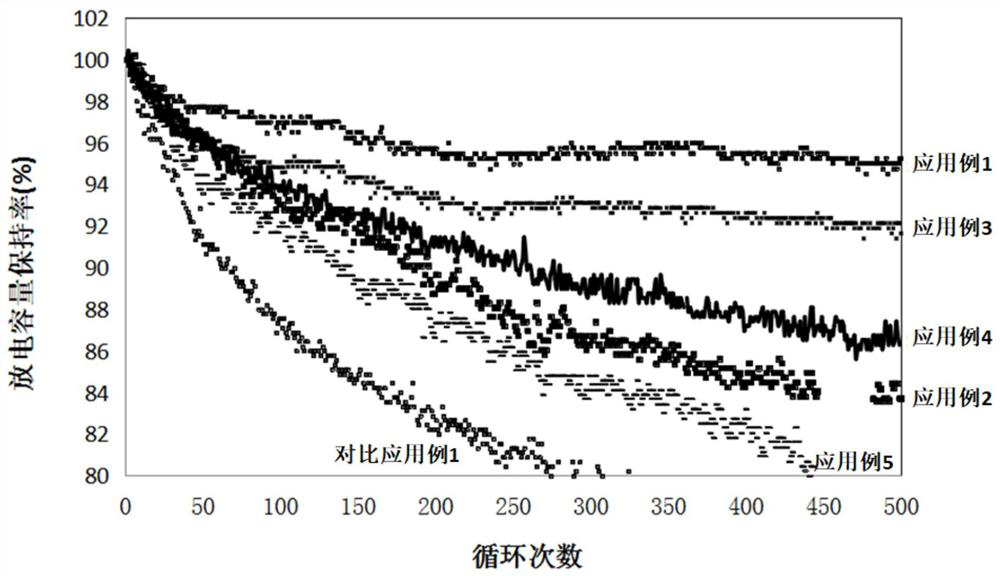

Examples

Embodiment 1

[0065] This embodiment provides a method for preparing a positive electrode slurry for a lithium ion battery, the preparation method comprising the following steps:

[0066] (1) Mix the positive electrode active powder nickel cobalt lithium manganate and the conductive agent powder T300 carbon fiber, and obtain the first powder after degassing; the degassing process is carried out simultaneously with heating and vacuuming, and the heating temperature is 150°C , the absolute vacuum degree of vacuuming is 0.005Pa; the time of degassing treatment is 20min;

[0067] (2) Pass the humidity-promoting gas carbon dioxide with a gauge pressure of 0.5 MPa into the first powder, and obtain the second powder after adsorption saturation;

[0068] (3) Stirring at a rate of 300 rpm for 15 minutes to mix the second powder and N-methylpyrrolidone, and obtain an intermediate slurry after degassing treatment; the degassing treatment is carried out simultaneously with heating and vacuuming, and th...

Embodiment 2

[0073] This embodiment provides a method for preparing a positive electrode slurry for a lithium ion battery, the preparation method comprising the following steps:

[0074] (1) Mix the positive electrode active powder nickel cobalt lithium aluminate and the conductive agent powder T700 carbon fiber, and obtain the first powder after degassing treatment; the degassing treatment is carried out simultaneously with heating and vacuuming, and the heating temperature is 125°C , the absolute vacuum degree of vacuuming is 0.003Pa; the time of degassing treatment is 15min;

[0075] (2) The moisture-promoting gas ammonia whose gauge pressure is 0.25 MPa is passed into the first powder, and the second powder is obtained after adsorption saturation;

[0076] (3) Stirring at a rate of 200rpm for 12.5min to mix the second powder and N-methylpyrrolidone, and obtain an intermediate slurry after degassing; the degassing process is performed simultaneously by heating and vacuuming, and the hea...

Embodiment 3

[0081] This embodiment provides a method for preparing a positive electrode slurry for a lithium ion battery, the preparation method comprising the following steps:

[0082] (1) Mix the positive electrode active powder lithium iron phosphate and the conductive agent powder M30 carbon fiber, and obtain the first powder after degassing; the degassing process is heating and vacuuming at the same time, and the heating temperature is 175 ° C. The absolute vacuum degree of vacuum is 0.008Pa; the time of degassing treatment is 25min;

[0083] (2) The moisture-promoting gas formaldehyde with a gauge pressure of 0.75MPa is passed into the first powder, and the second powder is obtained after adsorption saturation;

[0084] (3) Stirring at a rate of 400rpm for 17.5min to mix the second powder and N-methylpyrrolidone, and obtain an intermediate slurry after degassing; the degassing process is performed simultaneously by heating and vacuuming, and the heating temperature is 95°C , the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com