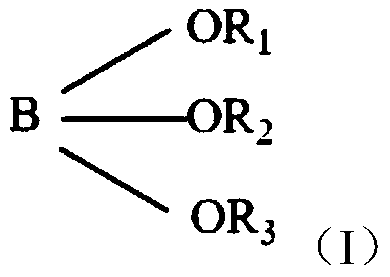

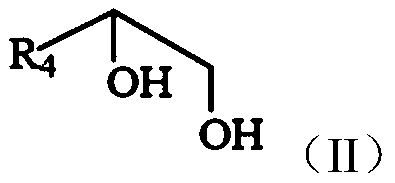

Boron-containing dopant slurry and application thereof

A boron doping and slurry technology, applied in the directions of diffusion/doping, electrical components, crystal growth, etc., can solve the problems of high cost, high cost of silicon ball preparation, high temperature, etc., to prevent aggregation, reduce the influence of attenuation, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1) Trihexyl borate 35g, 1,2-butanediol 20g, decyl dihydroxyethylamine 2g, erucic acid dimethyl ammonium acetate 1.5g, polyvinyl alcohol 0.8g, calcium oxide 18g, capric acid Add 1.5 g of stearyl alcohol ester and 23 g of water into the reaction kettle in sequence, and stir and mix evenly at 70 ° C to obtain the boron-containing dopant slurry;

[0057] 2) Select a P-type oriented monocrystalline silicon wafer with a resistivity of 1-3Ω·cm, after conventional cleaning, polishing and pickling, and then print the slurry obtained in step 1) on the silicon wafer. The printing pattern is a line shape structure, with a line width of 100 microns and a line spacing of 1.5 mm; after printing, dry at 300°C for 2 to 3 minutes;

[0058] 3) Place the silicon wafer treated in step 2) in a chain diffusion furnace for boron diffusion. The diffusion temperature is controlled at 775-780°C, and the diffusion time is controlled at 15-18 minutes; the resistance after diffusion is 58-67Ω / □ ; ...

Embodiment 2

[0061] 1) Diheptyl methoxy borate 35g, 1,2-butanediol 20g, dodecyl dihydroxyethylamine 2g, erucic acid dimethyl ammonium acetate 1.5g, polyvinyl alcohol 0.4g, oxidation Add 10g of magnesium, 1.5g of stearyl laurate, and 30g of water into the reaction kettle in sequence, and stir and mix evenly at 70°C to obtain a boron-containing dopant slurry;

[0062] 2) Select a P-type oriented monocrystalline silicon wafer with a resistivity of 1-3 Ω·cm, after conventional cleaning, polishing and pickling, and then print the slurry obtained in step 1) on the silicon wafer. The printing pattern is a circle Dot structure, 80 microns in diameter, 400 microns center-to-center; dry at 300°C for 1 to 2 minutes after printing;

[0063] 3) Place the silicon wafer treated in step 2) in a tubular diffusion furnace for boron diffusion, the diffusion temperature is controlled at 825-830°C, the diffusion time is controlled at 30 minutes, and the diffusion resistance is 60-70Ω / □; After the borosilicat...

Embodiment 3

[0065] 1) Dibutyl methoxy borate 45g, 1,2-hexanediol 10g, dodecyl dihydroxyethylamine 3g, oleic acid dimethyl ammonium acetate 1.5g, polyvinyl alcohol 1.3g, oxidation Add 5g of magnesium, 5g of calcium oxide, 1.5g of stearyl acetate, and 20g of water into the reaction kettle in sequence, and stir and mix evenly at 70°C to obtain a boron-containing dopant slurry;

[0066] 2) Select a P-type oriented monocrystalline silicon wafer with a resistivity of 1-3Ω·cm, go through conventional cleaning, alkali texturing and pickling; then print the slurry obtained in step 1) on the silicon wafer, and after printing Dry at 300°C for 2 to 3 minutes;

[0067] 3) Place the silicon wafer treated in step 2) in a chain diffusion furnace for boron diffusion, the diffusion temperature is controlled at 740-745°C, and the diffusion time is controlled at 15-20 minutes; the resistance after diffusion is 60-70Ω / □ ; After pickling to remove the borosilicate glass, the minority carrier lifetime of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com