LED transparent organosilicon pouring sealant with high refractive index and high viscosity and preparation method of LED transparent organosilicon pouring sealant

A silicone potting compound, high refractive index technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of poor refractive index and mechanical properties of silicone materials. , High moisture and oxygen permeability, difficult moisture and oxygen permeability, etc., to achieve the effect of increasing mechanical properties and bonding properties, improving refractive index, and small moisture and oxygen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

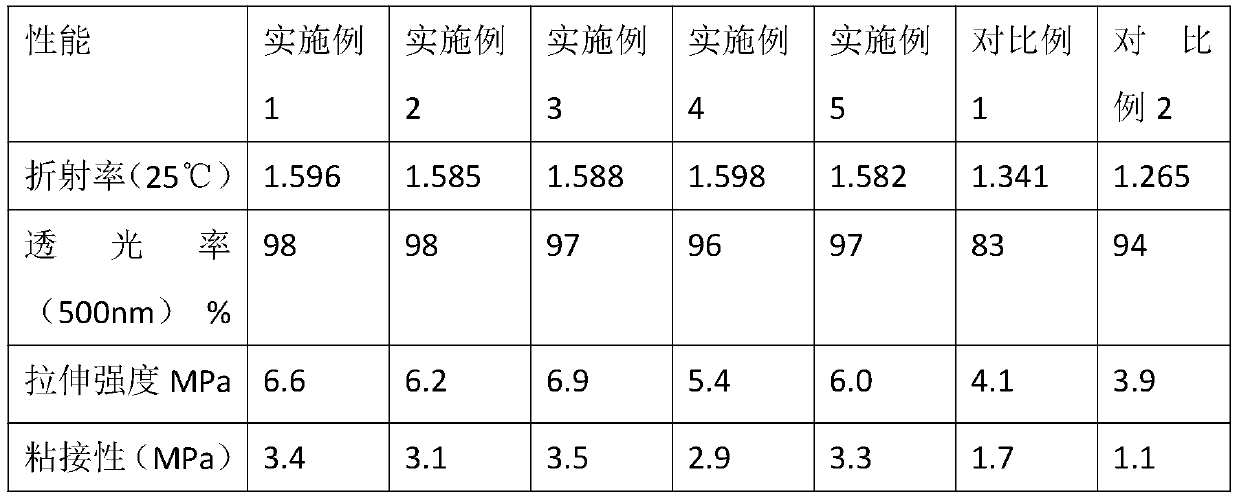

Examples

Embodiment 1

[0017] Example 1: A high refractive index and high viscosity LED transparent silicone encapsulant, which is composed of component one and component two:

[0018] The weight ratio of the component one raw material is: 65 parts of vinyl silicone oil, 20 parts of bleached shellac resin, 6 parts of hydrogen-containing silicone oil, 12 parts of melamine formaldehyde resin, 8 parts of beeswax liquid, and 0.8 parts of trisodium phosphate. Parts, 30 parts of modified gas phase titanium dioxide, the weight ratio of the component two raw materials: 12 parts of vinyl silicone oil and 0.6 parts of platinum catalyst.

[0019] Further, the preparation method of the modified vapor-phase titanium dioxide is: placing the dried vapor-phase titanium dioxide and vapor-phase aluminum oxide in a NaOH solution with a concentration of 10 mol / L, stirring and heating to 60° C., adding under heat preservation and stirring The epichlorohydrin solution with a mass ratio of 5:1 to the gas phase titanium dioxide...

Embodiment 2

[0026] Example 2: A high refractive index and high viscosity LED transparent silicone encapsulant, which is composed of component one and component two:

[0027] The weight ratio of the component one raw material is: 60 parts of vinyl silicone oil, 15 parts of bleached shellac resin, 5 parts of hydrogen-containing silicone oil, 8 parts of melamine formaldehyde resin, 5 parts of beeswax liquid, and 0.5 parts of trisodium phosphate. 15 parts by weight of modified gas phase titanium dioxide. The weight ratio of the two raw materials is: 10 parts of vinyl silicone oil and 0.4 parts of platinum catalyst.

[0028] Further, the preparation method of the modified gas phase titanium dioxide is the same as that of Example 1.

[0029] The method for preparing a high refractive index and high viscosity LED transparent silicone encapsulant includes the following steps:

[0030] (1) Mix bleached shellac resin and trisodium phosphate and heat to 80°C, keep warm and stir evenly;

[0031] (2) The beesw...

Embodiment 3

[0035] Example 3: A high refractive index and high viscosity LED transparent silicone encapsulant, which is composed of component one and component two:

[0036] The weight ratio of the component one raw materials is: 70 parts of vinyl silicone oil, 25 parts of bleached shellac resin, 8 parts of hydrogen-containing silicone oil, 15 parts of melamine formaldehyde resin, 10 parts of beeswax liquid, and 1 part of trisodium phosphate. Parts, 40 parts of modified gas phase titanium dioxide, the weight ratio of the second component: 15 parts of vinyl silicone oil and 0.8 parts of platinum catalyst.

[0037] Further, the preparation method of the modified gas phase titanium dioxide is the same as that of Example 1.

[0038] The method for preparing a high refractive index and high viscosity LED transparent silicone encapsulant includes the following steps:

[0039] (1) Mix bleached shellac resin and trisodium phosphate and heat to 90°C, keep warm and stir evenly;

[0040] (2) The beeswax liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com