A special nylon material for Velcro and its preparation method

A Velcro and nylon technology, applied in the field of nylon materials, can solve the problems of poor crystallization behavior and mold release, and achieve the effect of reducing surface energy, improving fluidity, and reducing the degree of easy dirt and sticky dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

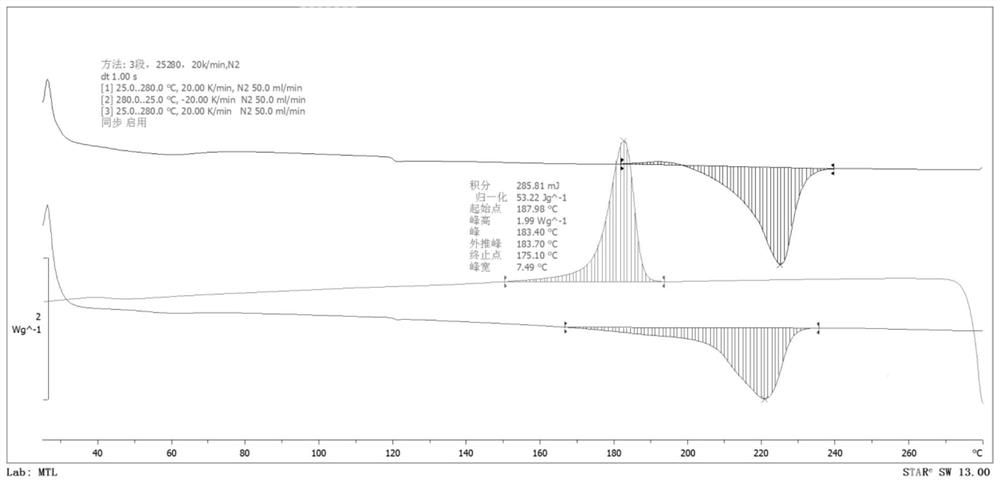

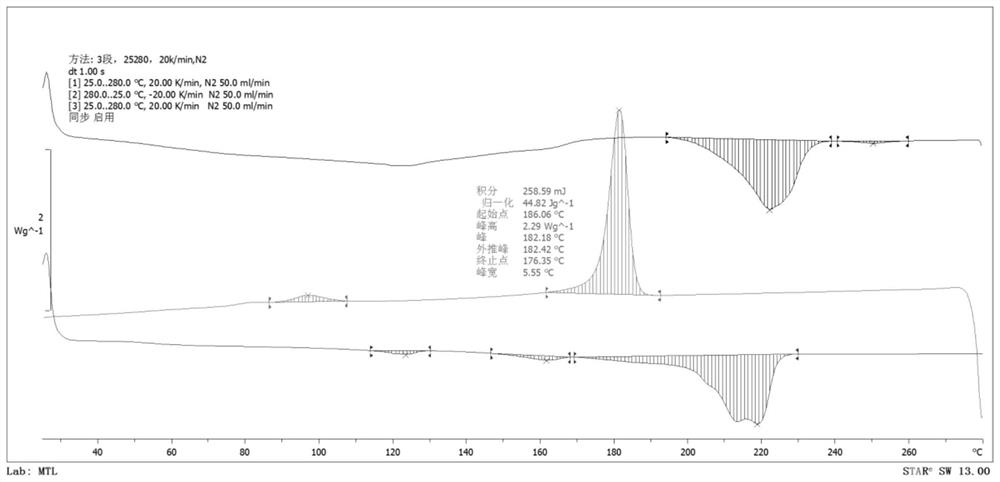

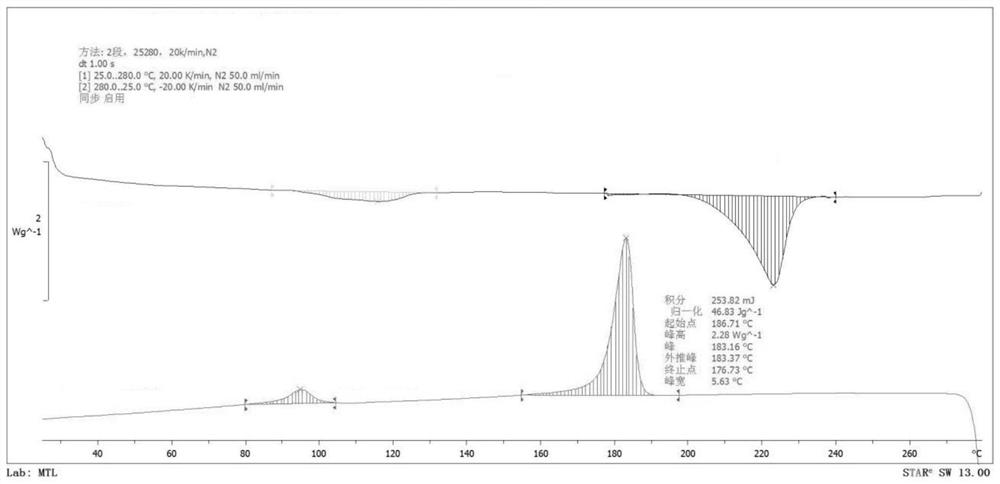

Image

Examples

Embodiment 2

[0062] The polyamide of embodiment 2 selects PA6, η=2.8, Zhonglun SC28; Toughening agent selects 10% Jiayong CMG9801 and 10% Dupont E100 for use; Dendrimer selects CYD-701M for use; Nucleating agent selects Bruggmann for use P22; 2% white oil and 0.5% calcium stearate are selected as the release agent; N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) is selected as the antioxidant Hexamethylenediamine; other additives include 0.1% anti-hydrolysis agent, 0.2% coupling agent and 0.2% plasticizer.

Embodiment 3

[0063] The polyamide of embodiment 3 selects PA6, η=2.8, Zhonglun SC28 for use; Toughener selects DuPont E100 for use; Dendrimer selects CYD-701D for use; Nucleating agent selects calcium montanic acid salt CAV102 for use; Release agent selects stearic acid for use Calcium; N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine is selected as an antioxidant; other additives include 0.1% coupling agent and 0.1% lubricant.

Embodiment 4

[0064] The polyamide of embodiment 4 selects PA6, η=2.4, Xinhui Meida M2400; Toughener selects DuPont N416 for use; Dendrimer selects CYD-701D for use; Nucleating agent selects calcium montanic acid salt CAV102 for use; Release agent selects silicon for use Ketone powder; N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine is selected as the antioxidant; other additives include 0.2% anti-hydrolysis agent, 0.1 % plasticizer and 0.2% pigment.

[0065] The present invention also provides the comparative example 1-4 raw material proportioning (each component is by weight percentage) as table 2:

[0066] Table 2

[0067]

[0068]

[0069] Among them, the polyamide of comparative example 1 is selected: PA6, η=2.4, Xinhui Meida M2400; the release agent is selected: white oil 1% and calcium stearate 0.5%; the antioxidant is selected: N, N'-bis- (3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine; other additives include: 0.1% antistat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com